A method for producing acrylic acid by fermentation of Saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and Saccharomyces cerevisiae, which is applied in the field of biosynthesis of acrylic acid, can solve the problems of unclear synthesis mechanism, low synthesis efficiency, and complex synthesis pathways, and achieve good environmental and occupational health, easy production cost, and easy industrial transformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings. The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

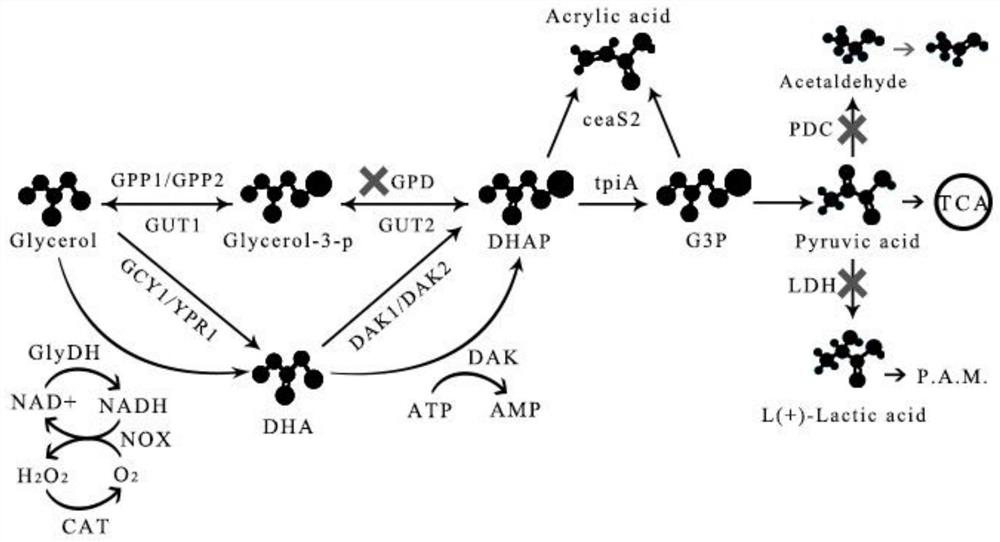

[0041] A method for producing acrylic acid by fermentation of Saccharomyces cerevisiae, the synthetic route of which is as follows figure 1 Said, the synthesis method uses glycerol as a raw material, Saccharomyces cerevisiae as a host bacterium, and is completed through the catalysis of several enzymes in the host bacterium; the host bacterium is constructed and obtained according to the following method:

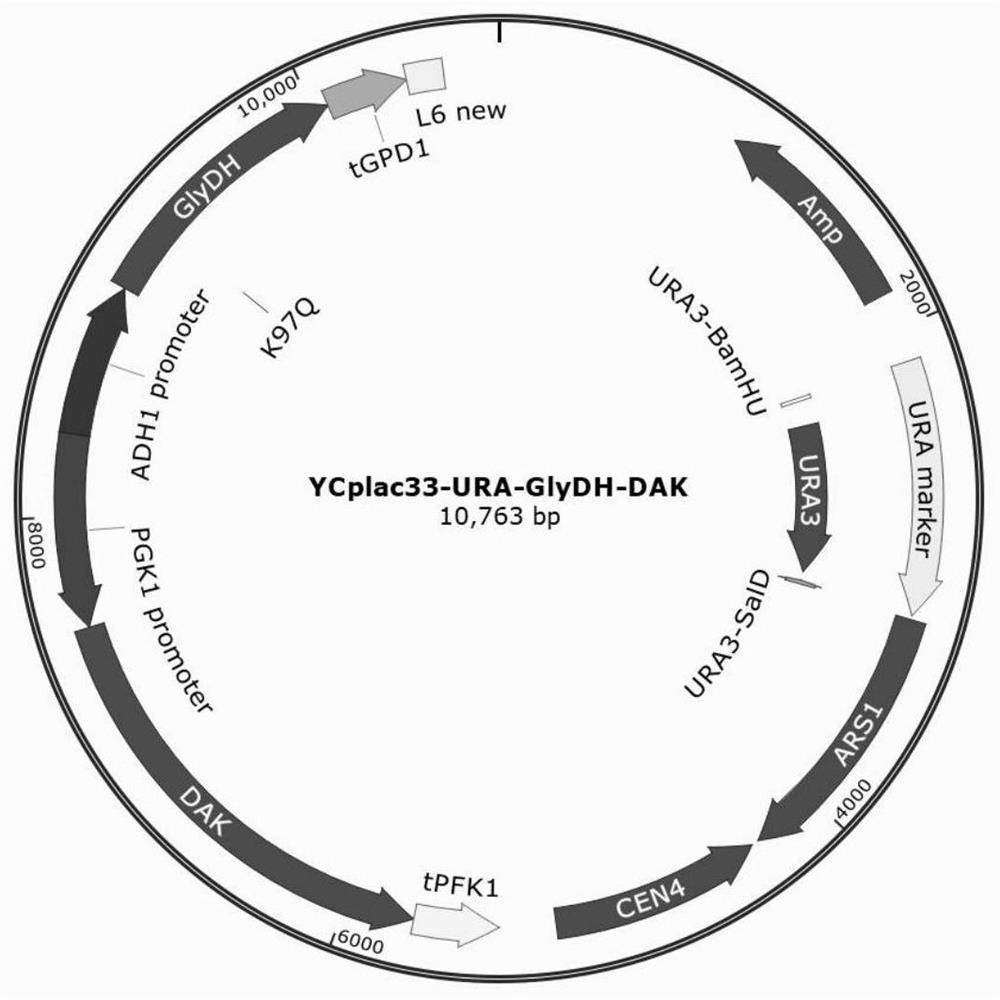

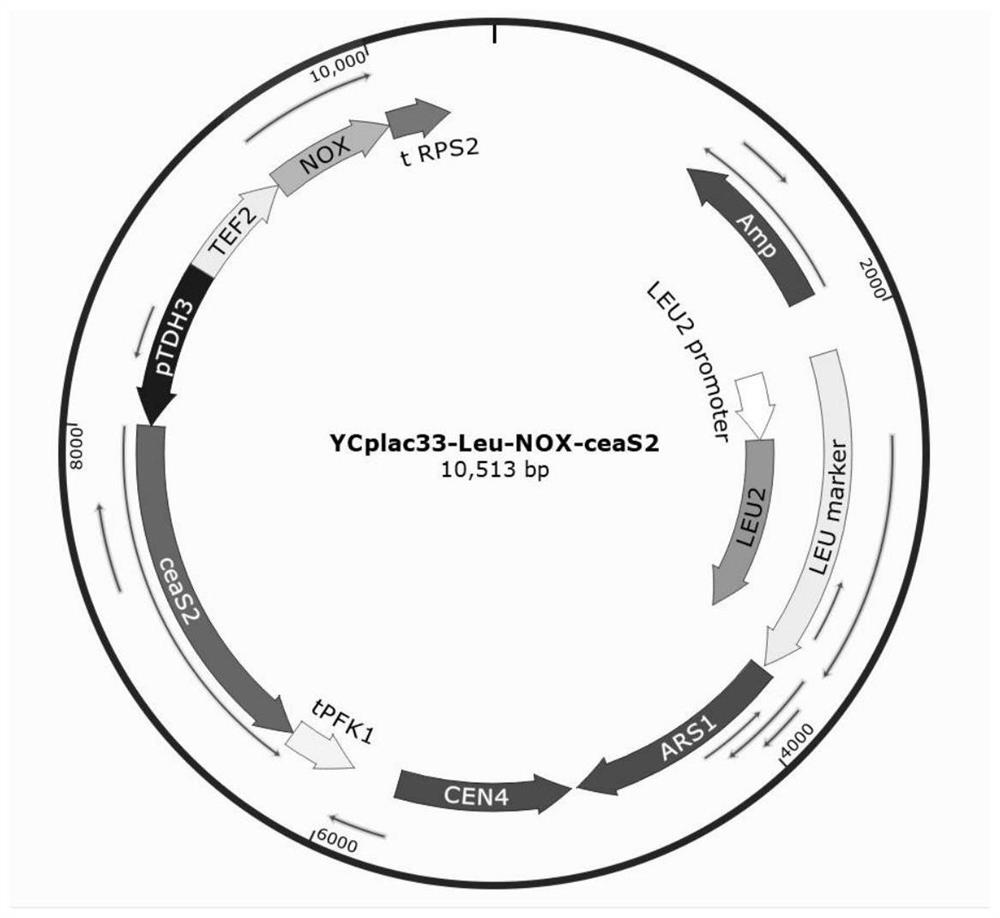

[0042] 1) Optimize the codons of the genes GlyDH and DAK according to the codon preference of Saccharomyces cerevisiae, and then use the bidirectional promoter to construct the two genes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com