Furnace body in cooling section of industrial reaction furnace

A technology of industrial reaction and cooling section, which is applied in the direction of furnaces, furnace components, furnace cooling devices, etc., and can solve problems such as large amount of coolant usage, low cooling efficiency, and complex structure of the furnace body in the cooling section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

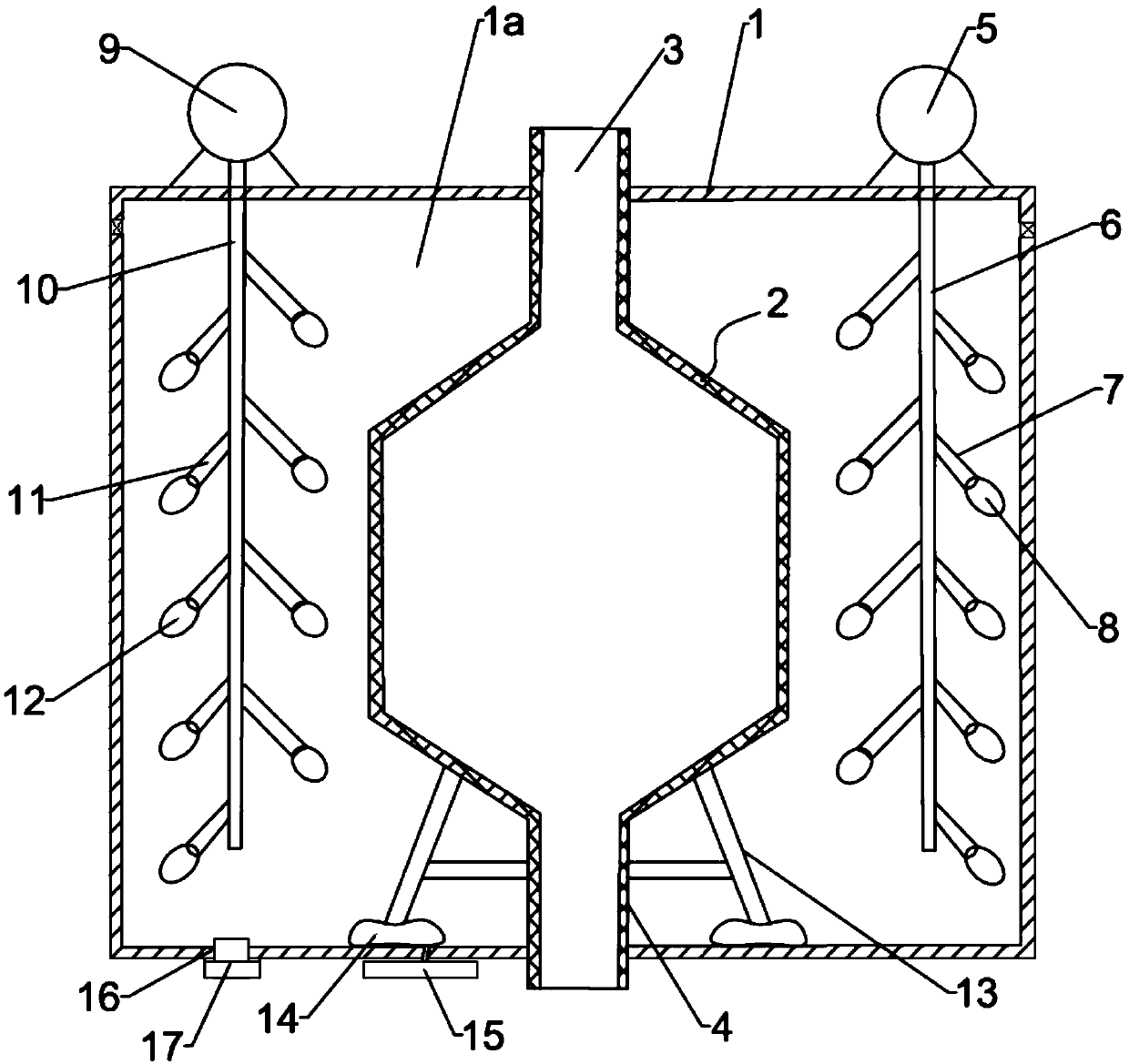

[0016] Please refer to the attached figure 1 As shown, the present invention provides a furnace body in the cooling section of an industrial reaction furnace, comprising an outer furnace body 1 with a cooling chamber 1a, a cooling furnace body 2 is arranged in the cooling chamber 1a, and the top of the cooling furnace body 2 passes through an upper through pipe 3 Pass through the outer furnace body 1 to communicate with the outside, and the bottom of the cooling furnace body 2 passes through the outer furnace body 1 to communicate with the outside through the lower through pipe 4; the top outer wall of the outer furnace body 1 is provided with a first motor 5, and the cooling chamber 1a The first rotating rod 6 driven by the first motor 5 is arranged inside, and the first rotating rod 6 is arranged close to the cooling furnace body 2. On the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com