Heat exchange water tank provided with double coiled pipes

A technology for exchanging water tanks and double coils, which is applied in the direction of heat exchangers, indirect heat exchangers, fixed conduit components, etc. Problems such as water outlet from the water pipe, to achieve the effect of accelerating the water outlet speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

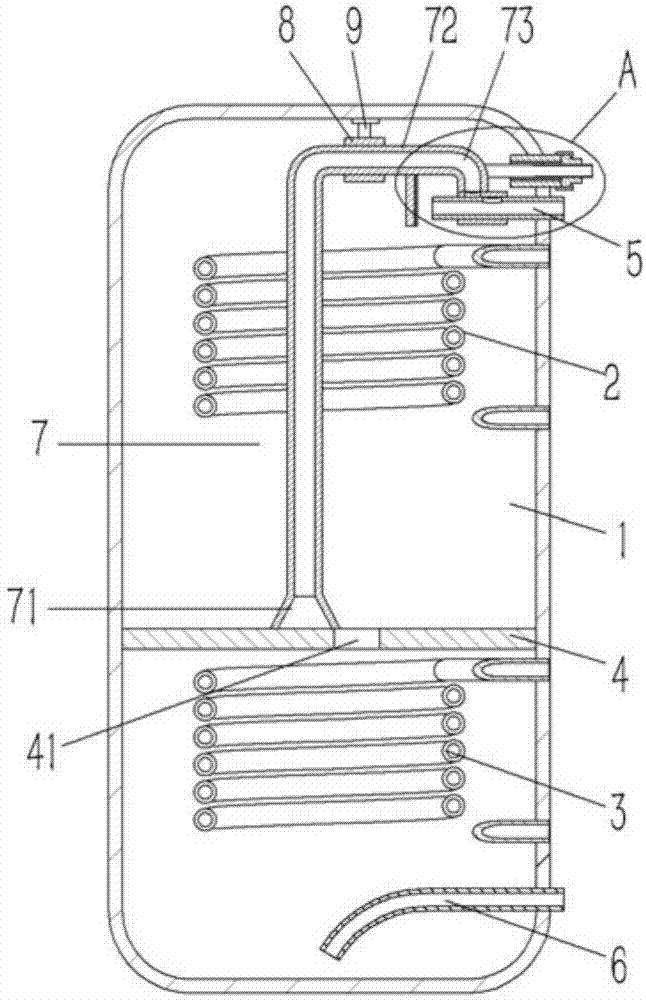

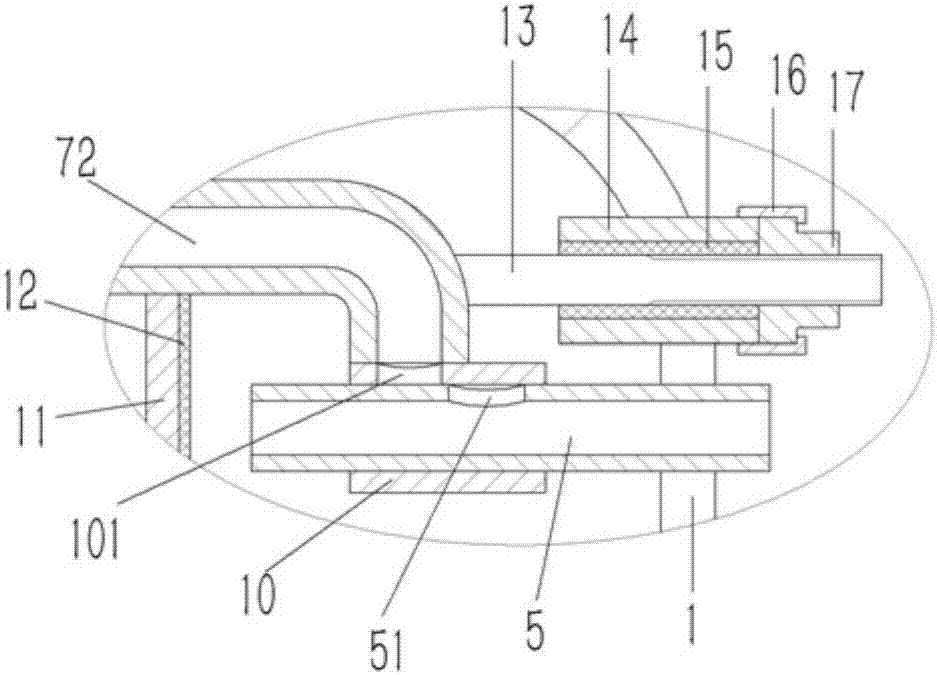

[0015] Example: see figure 1 , 2 As shown, a double-coil heat exchange tank includes an inner tank 1 of the heat exchange tank, an upper coil 2 and a lower coil 3 are respectively inserted at the upper and lower ends of the inner tank 1, and the upper coil 2 and the lower coil 3 are respectively inserted. The lower coils 3 are all fixed on the inner tank 1, the upper coil 2 and the lower coil 3 and the inner tank 1 are inserted with a horizontal partition 4, and the partition 4 is fixed on the inner wall of the inner tank 1, so The top and bottom ends of the liner 1 are distributed and fixed with water inlet pipe 5 and water outlet pipe 6, and the upper coil pipe 2 is inserted with a vertical diversion pipe 7, and the upper end of the diversion pipe 7 is bent to form a horizontal guide. Pipe 72, the guide tube 72 is inserted with a guide sleeve 8, the guide sleeve 8 is fixed on the positioning bracket 9, the positioning bracket 9 is fixed on the inner tank 1, and the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com