Natural gas high-flow real flow verification system

A technology of large flow and natural gas, applied in the field of large flow real-flow verification system of natural gas, can solve the problems of low measurement uncertainty of the system, inability to accurately verify small flow, and large capacity of the verification pipeline, so as to improve the measurement uncertainty of the system. The effect of improving the speed, verification function, and simplifying the setting of the retractor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

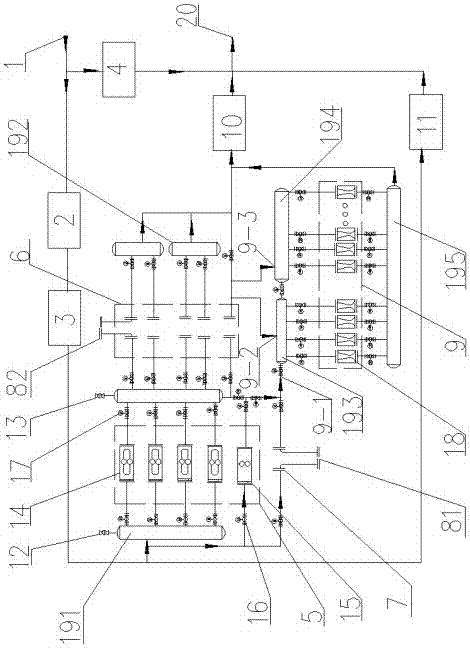

[0033] This embodiment provides a natural gas large flow real flow verification system, such as figure 1As shown, it includes an air inlet 1, a filter separation device 2, a pressure regulating valve group 3, a bypass flow regulating valve group 11 and an exhaust port 20 connected in sequence, including between the air inlet 1 and the exhaust port 20 The over-station regulating valve group 4 includes a verification station 6, a high-precision verification station 7, a working level standard device 5, a secondary standard device 9, a main flow regulating valve group 10 and a mobile verification vehicle interface, which is characterized in that: In addition to being connected with the bypass flow regulating valve group 11, the lower end of the pressure-stabilizing regulating valve group 3 is also connected with a working-level standard device 5 and a high-precision verification platform 7 respectively, and the working-level standard device 5 includes 4 parallel sets The turbine...

Embodiment 2

[0054] In this embodiment, on the basis of Embodiment 1, the described work-level standard device 5 is specifically described, as figure 1 The diameter of 3 of the 4 turbine flowmeters 14 of the working level standard device 5 is 250mm, the diameter of 1 is 150mm, the diameter of 1 waist wheel flowmeter 15 is 100mm, the turbine flowmeter 14 and An ordinary electric valve 16 is provided between the first manifold 191 at the upper end, a forced sealing ball valve 17 is provided between the turbine flowmeter 14 and the first manifold 191 at the lower end, and the upper end of the working standard device 5 is first A nitrogen purge pipeline 12 is provided on the manifold 191 , and a venting pipeline 13 is provided on the first manifold 191 at the lower end.

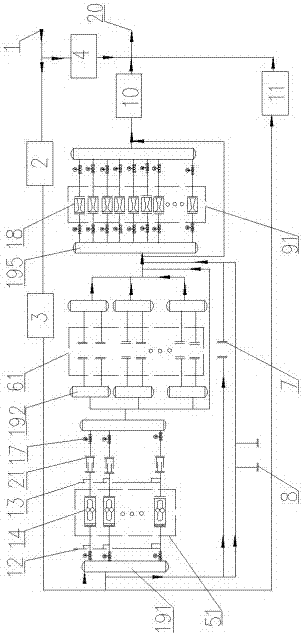

[0055] Such as figure 2 , the working-level standard device 5 in the traditional natural gas large-flow real-flow verification system generally uses the turbine flowmeter 14 as the working-level standard meter, but the smal...

Embodiment 3

[0059] In this embodiment, on the basis of Embodiment 1, the secondary standard device 9 is described in detail, as figure 1 As shown, the secondary standard device 9 includes a critical flow Venturi nozzle 18, a third manifold 193 and a fourth manifold 194 at the upper end and a fifth manifold 195 at the lower end, and the lower end of the third manifold 193 is provided with 4 The critical flow Venturi nozzles 18 that are arranged side by side, the lower end of the fourth manifold 194 can be provided with 11 parallel critical flow Venturi nozzles 18, and the lower ends of all the critical flow Venturi nozzles 18 are connected to the fifth manifold 195; The first inlet 9-1 of the secondary standard device and the second inlet 9-2 of the secondary standard device are arranged on the third manifold 193, and the third inlet 9-3 of the secondary standard device is arranged on the fourth manifold 194 superior.

[0060] The diameter of the 4-way critical flow Venturi nozzle 18 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com