Press hole device for auto parts

A technology for auto parts and pressing rods, which is applied in drilling/drilling equipment, portable drilling rigs, metal processing equipment, etc., can solve the problems of easy damage of auto parts, and the depth achieved is easy to control and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

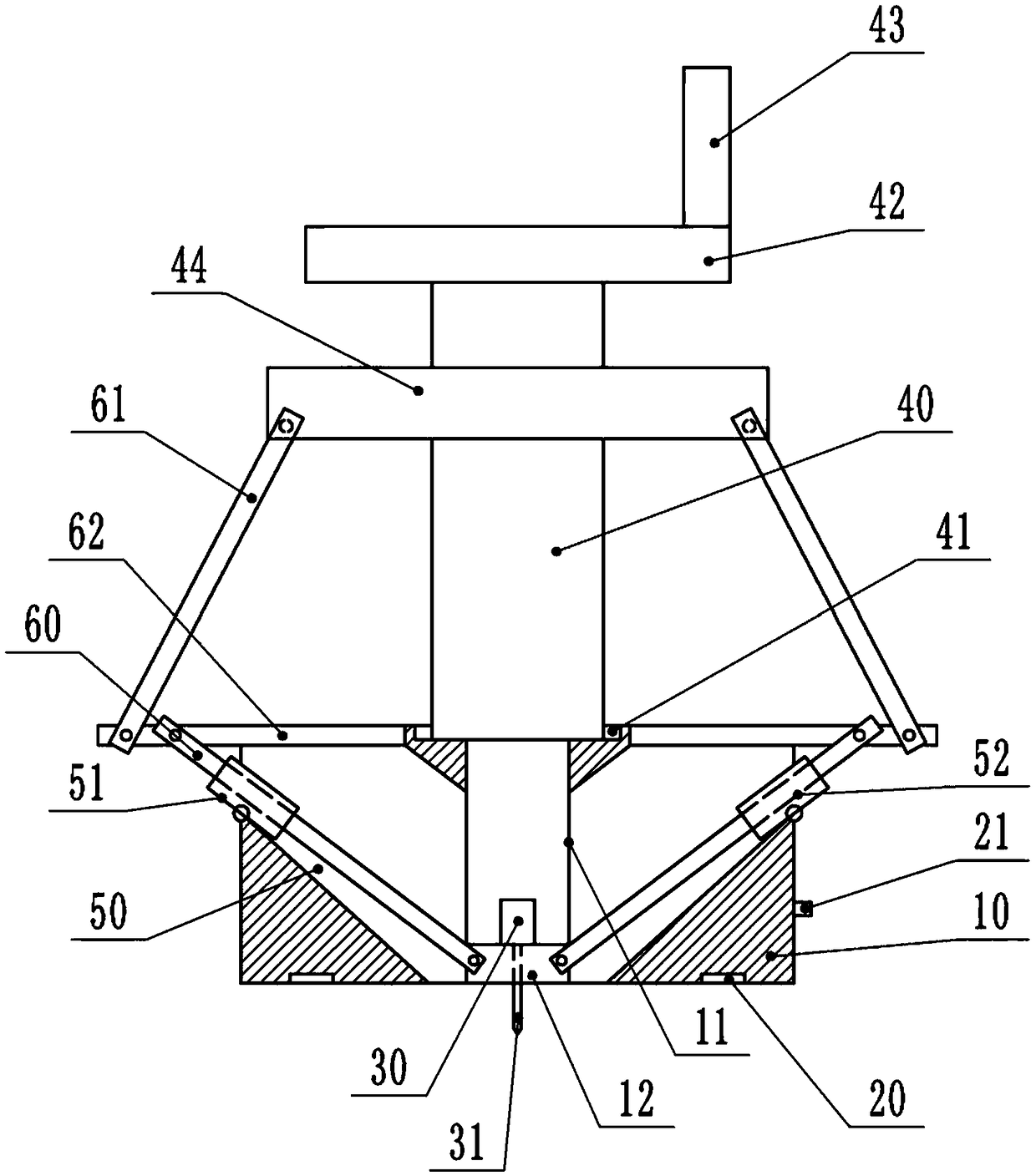

[0015] The reference signs in the accompanying drawings of the description include: base 10, sliding cavity 11, slider 12, electromagnet 20, switch 21, motor 30, drill bit 31, pole 40, bearing 41, turntable 42, handle 43, rotating frame 44 , Rotating cavity 50, rotating block 51, chute 52, depression bar 60, connecting rod 61, telescopic bar 62.

[0016] Such as figure 1 As shown, the pressure hole device for auto parts includes a base 10 and a support rod 40, as well as a plurality of pressure rods 60, connecting rods 61 and telescopic rods 62 with the same number. In this embodiment, the pressure rods 60, connecting rods There are four rods 61 and telescopic rods 62 . The slide chamber 11 in the vertical direction is set at the center of the base 10 , a slide block 12 is set up and down in the slide chamber 11 , a drill bit 31 is provided at the slide block 12 lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com