Injection molding device used for injection-molded component with zero rotating stop structure and double internal threads with different pitches

A technology for injection molded parts and internal threads, which is applied in the field of injection molding devices, and can solve problems such as double internal threads that cannot achieve simultaneous demoulding, damage to small pitch parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

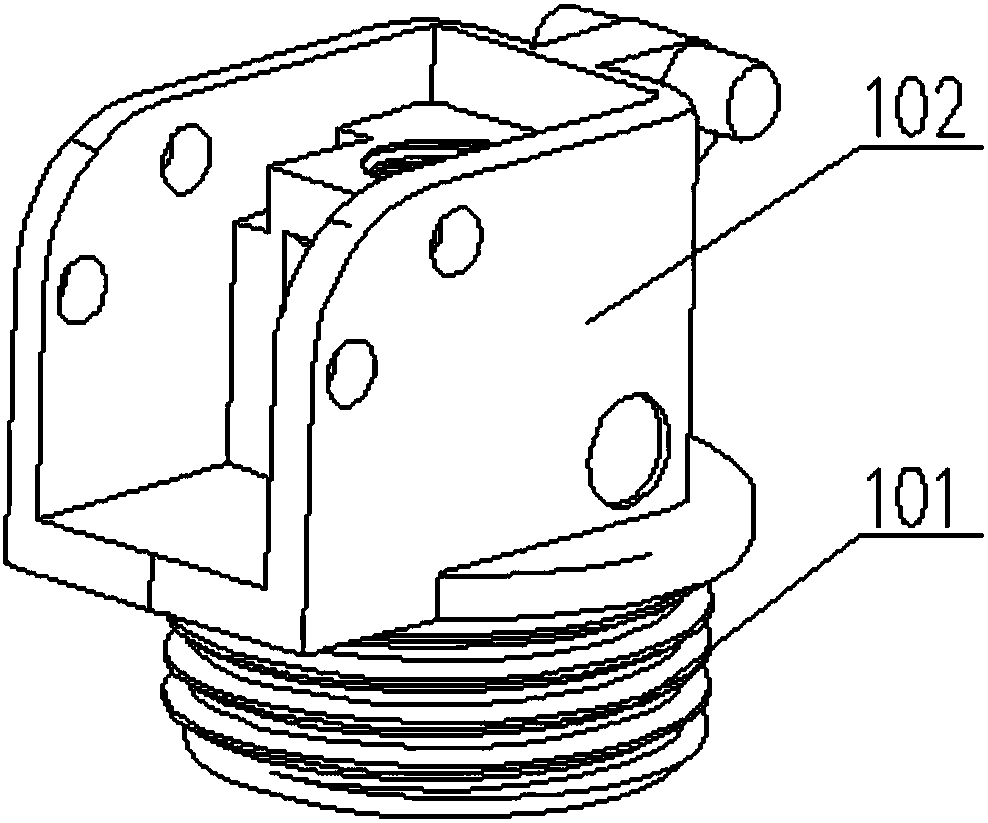

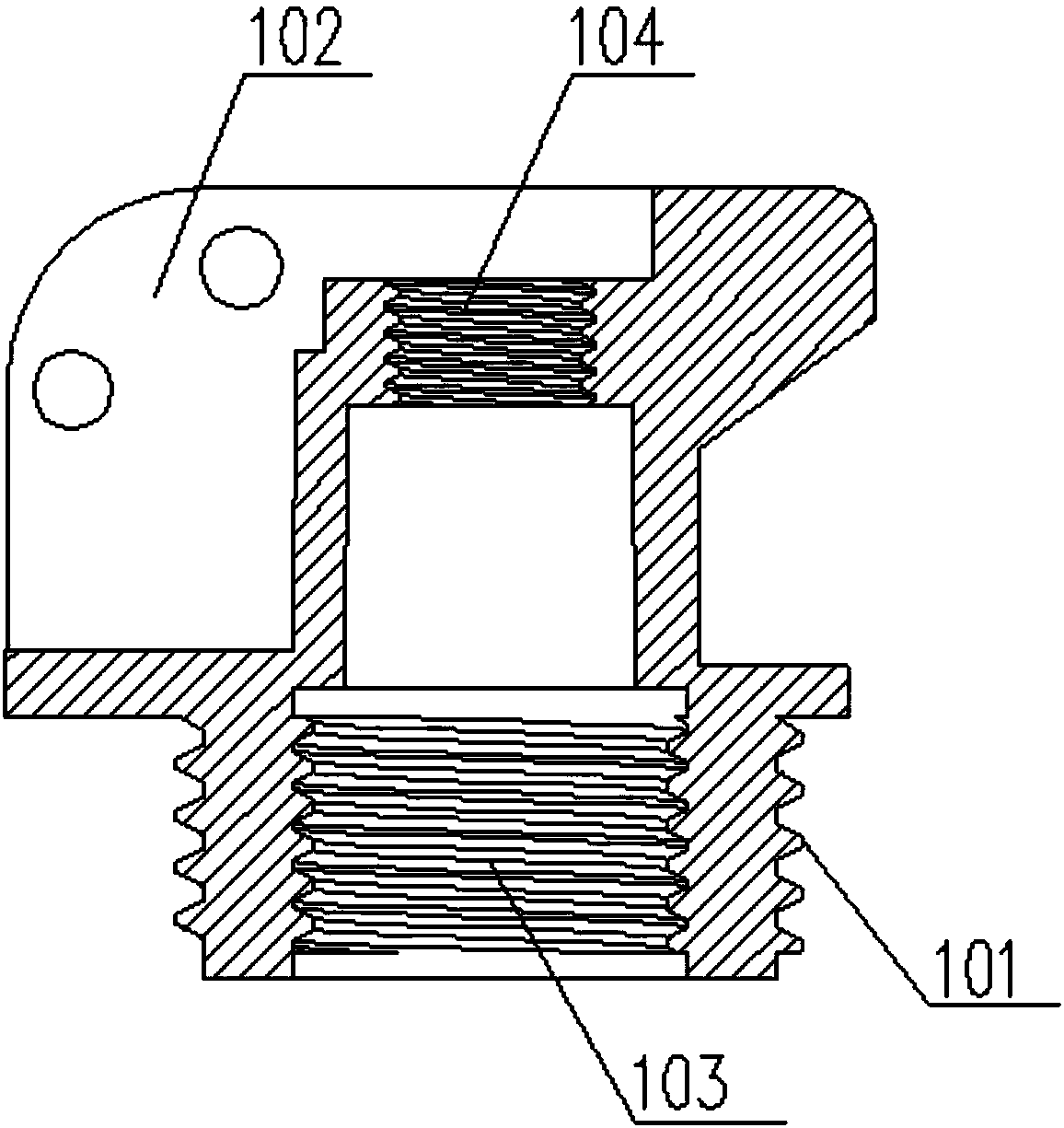

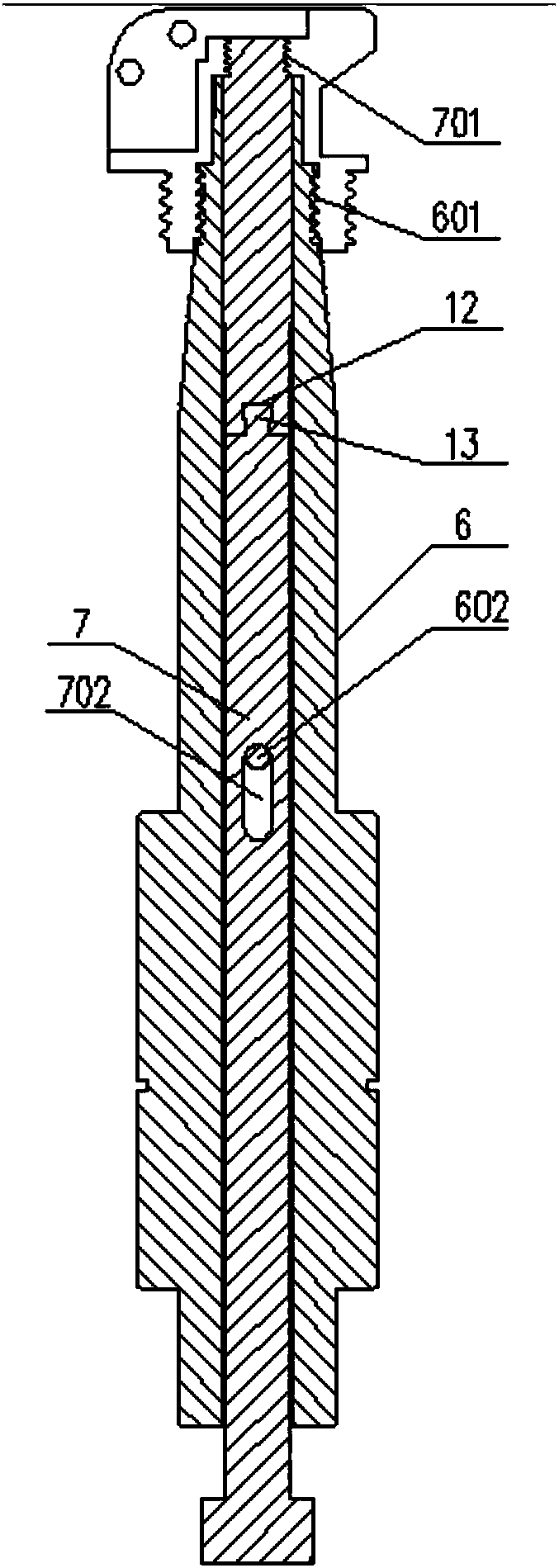

[0024] The present invention relates to an injection molding device for an anti-rotation structure and a double internal thread injection molded part with different pitches. The injection molded part 1 is a pipe fitting provided with an external thread 101 and two internal threads with different pitches, and the upper end of the pipe fitting is provided with a clamping structure 102 The injection molding device includes a moving module 2 with a front mold 201 and a fixed module 3 with two symmetrical sliders 302 and a rear mold. The front mold 201, the rear mold and the two sliders 302 are closed to form an injection molding cavity 4. The module 2 is provided with an injection hole 5 communicating with the injection cavity 4, the rear mold is a threaded shaft for rotary demoulding, and the fixed module 3 is also provided with an ejection mechanism for the injection molded part 1 and a power mechanism for the threaded shaft, The fixed module 3 is provided with a clamping mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com