Folding type seat

A folding seat technology, applied in vehicle seats, movable seats, detachable/non-detachable seats, etc., can solve problems such as poor structural strength, loud collision sound, and abnormal collision noise, and achieve strong load-bearing capacity , reduce the vertical height, reduce the effect of bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

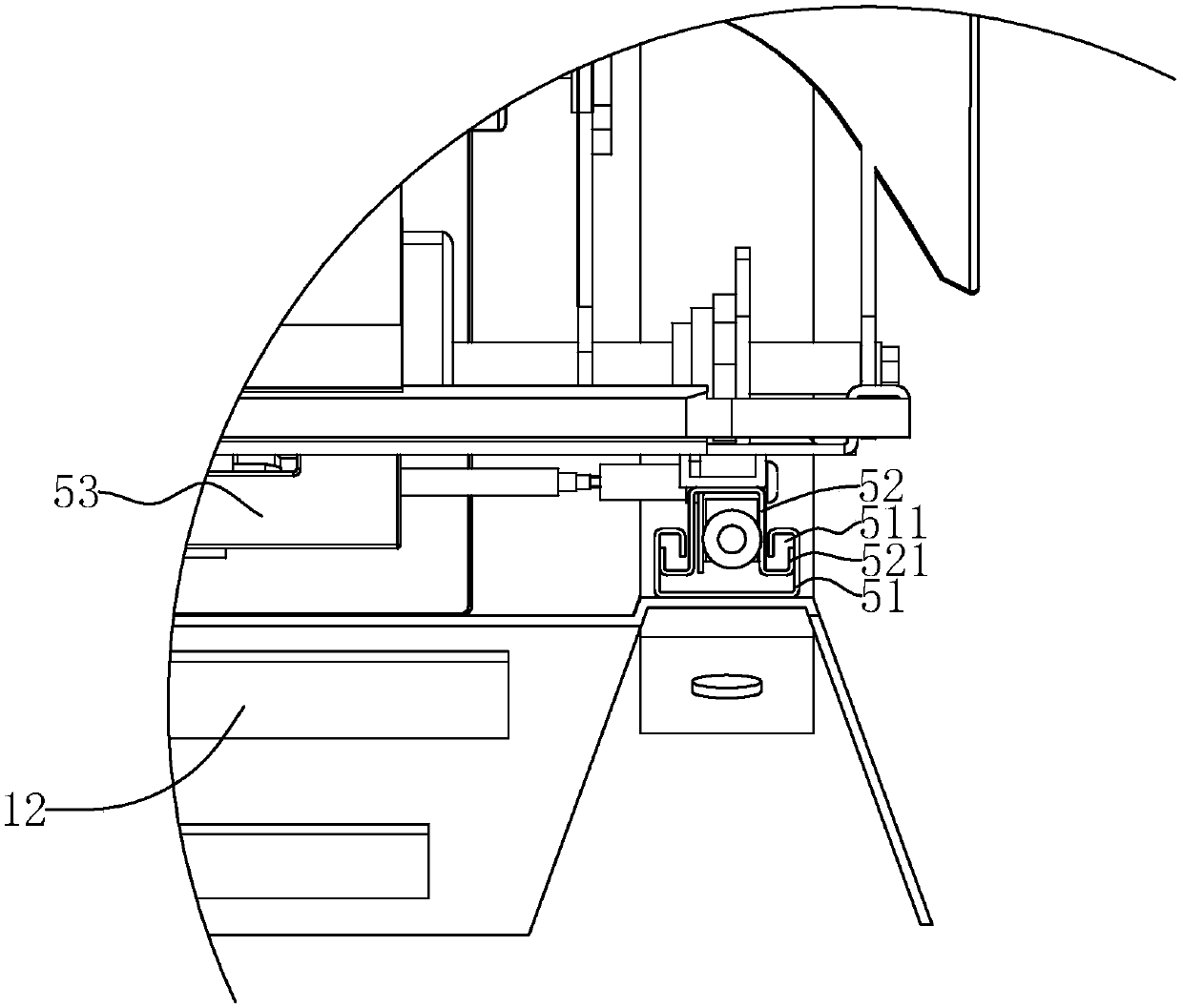

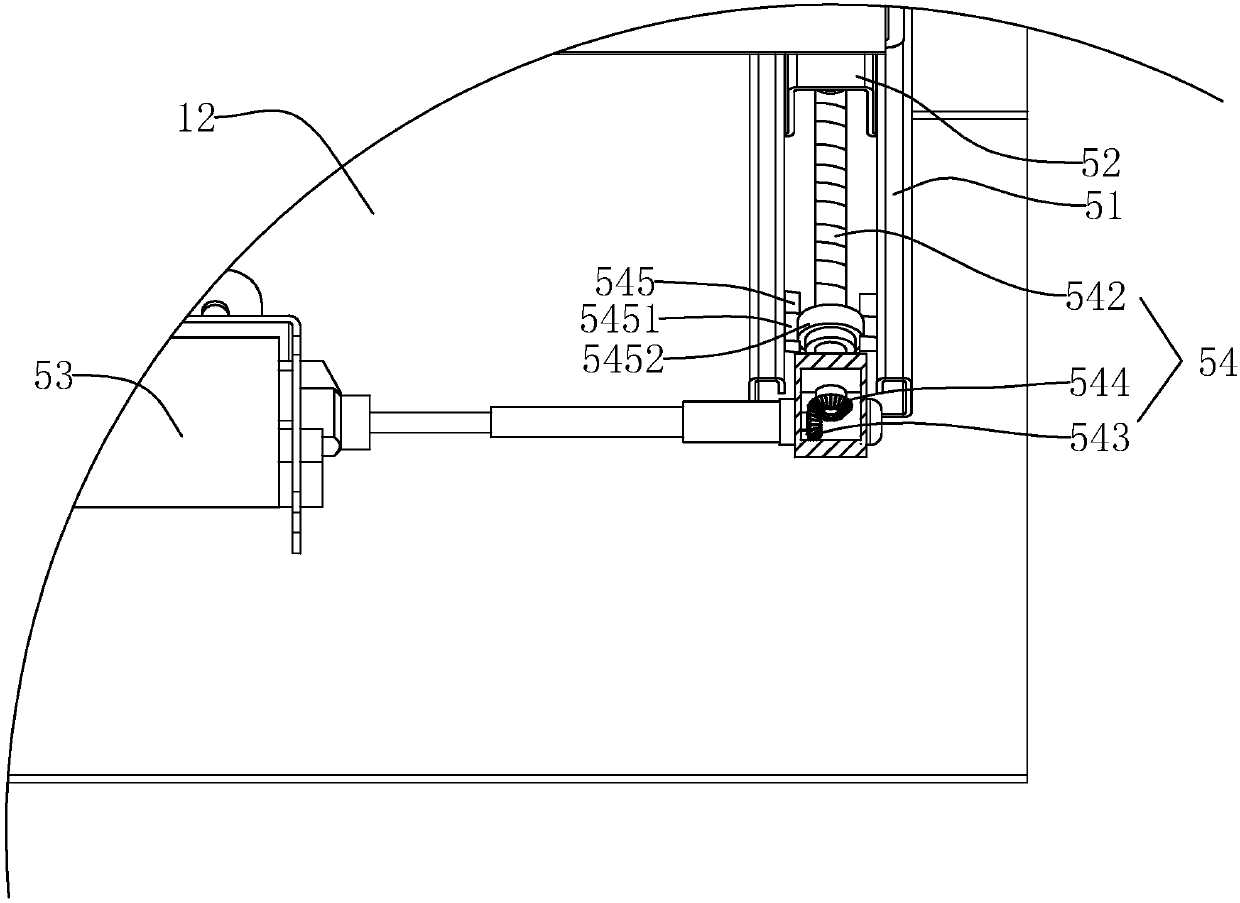

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

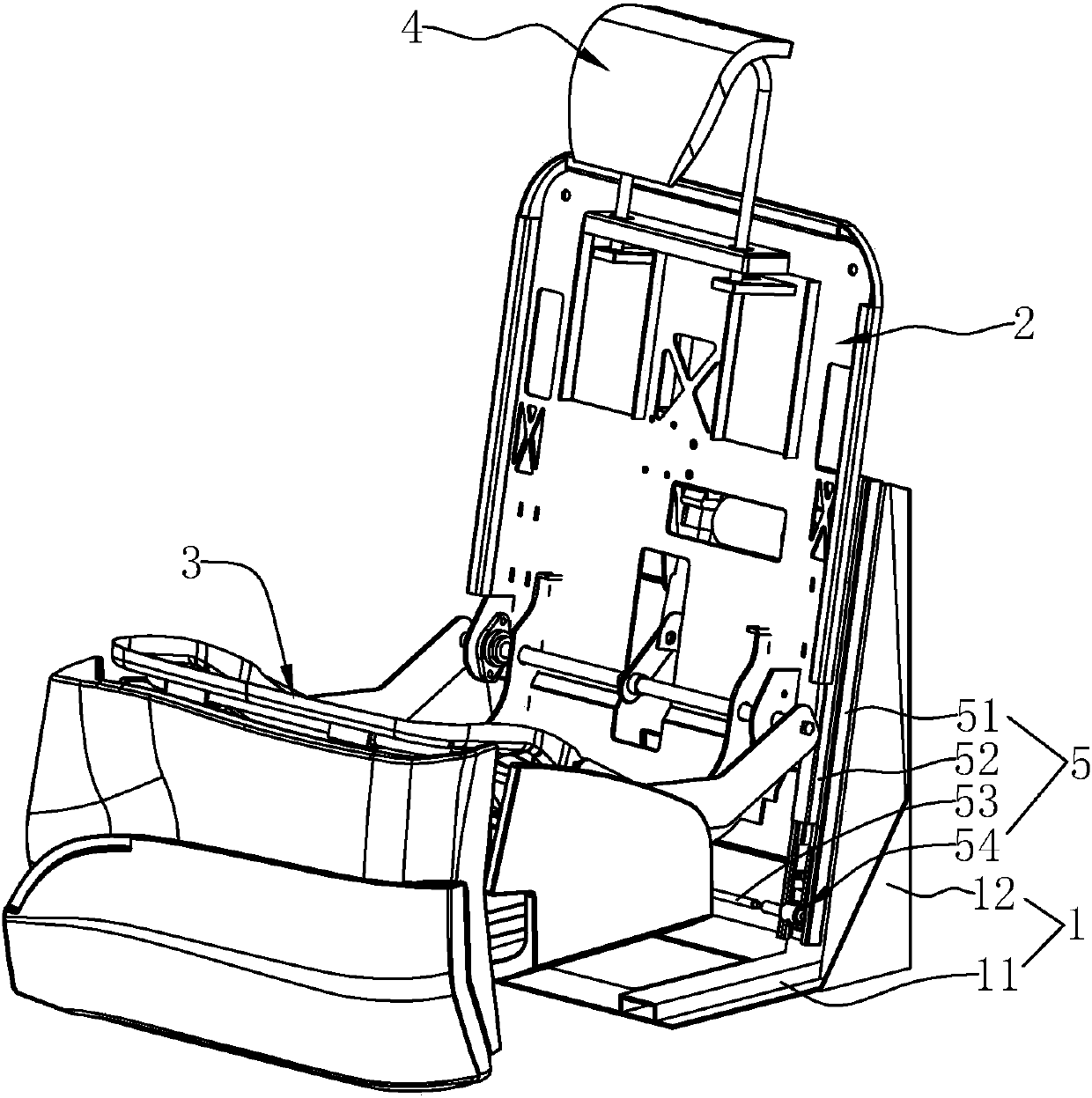

[0040] A folding seat such as figure 1 As shown, it includes a base 1, a back frame 2 slidably arranged on the base 1, a seat cushion frame 3 rotated on the lower side of the back frame 2, and a headrest fixing plate 4 arranged on the upper side of the back frame 2, wherein the seat The cushion frame 3 can rotate 90 degrees along the horizontal axis, so that the seat cushion is rotated to an open state for passengers to ride or a vertically folded state to reduce the space occupancy rate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com