Anti-overflow device at roller water injection port and roller washing machine

A water injection port and anti-overflow technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of increased cost and difficulty of assembly, increased water and foam overflow, and defective parts, etc., to achieve good anti-overflow effect, The effect of simple parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

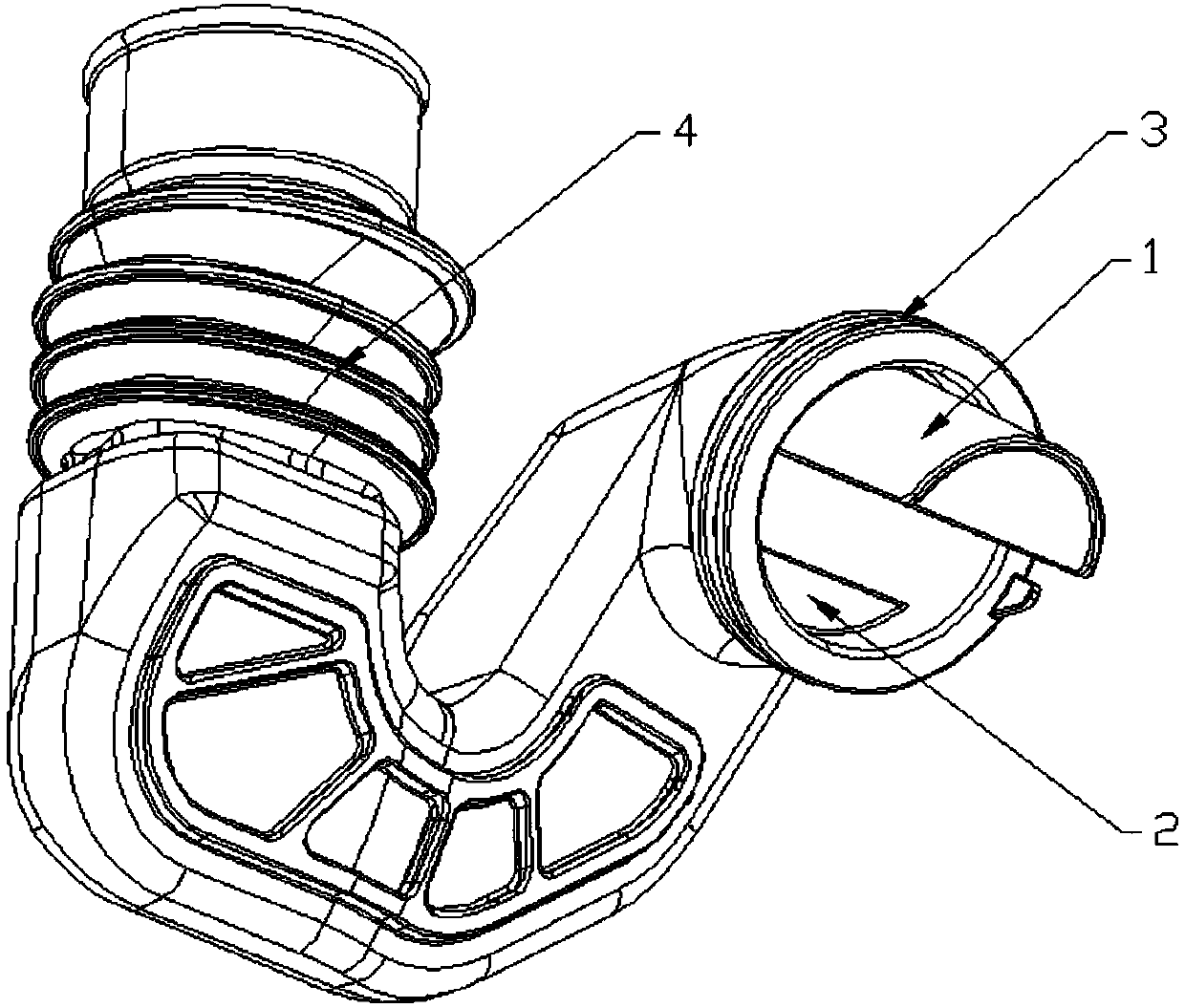

[0041] Such as Figure 2-4 As shown, in this embodiment, the baffle plate 1 of the anti-overflow device of the water injection port of the drum and the water injection end 3 of the water injection hose 4 are integrally formed, and there is no need for assembly before use, and the components are simple and reliable. And good economy.

[0042] The baffle 1 is an arc-shaped plate protruding from the inner wall of the water injection head 3 to match the water injection port. Preferably, the inner surface of the baffle 1 and the inner surface of the water injection head 3 are smooth transition. It can also be a curved plate or an angled prismatic plate that does not match the water injection port. This kind of arc plate or angled prismatic plate can also play the role of baffle, even when the boundary of the baffle exceeds the diameter of the water injection port. The baffle effect is better, but this kind of baffle is not easy to be integrally formed with the water injection end...

Embodiment 2

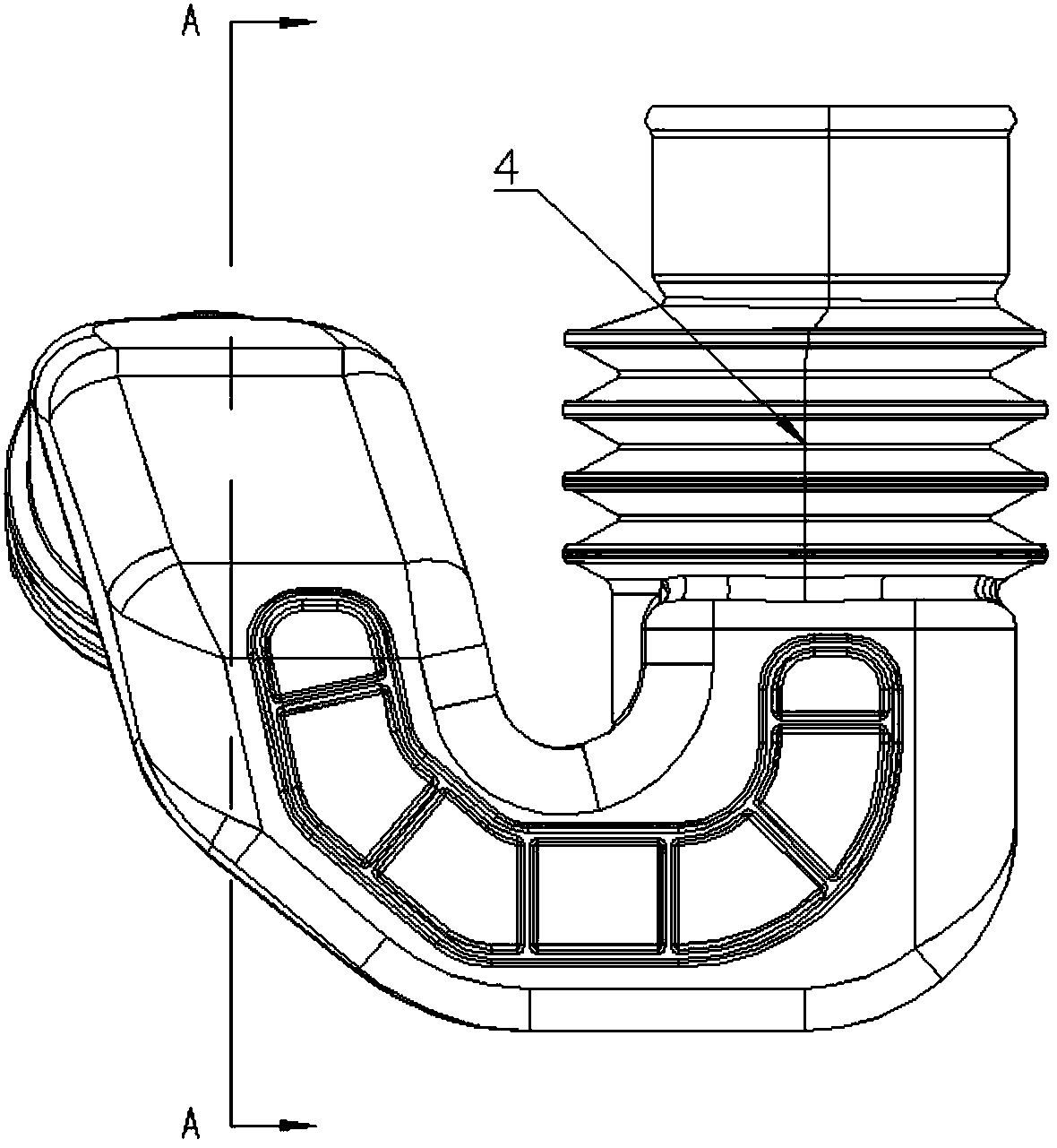

[0047] Such as Figure 5 As shown, in this embodiment, the anti-overflow device of the water injection port of the drum and the water injection end 3 of the water injection hose 4 are separate structures, and the two are connected by threads.

[0048] The baffle is provided with an integrally formed connecting pipe 7 , which is fixed by screwing the connecting pipe 7 and the water injection head 3 . More preferably, the outer cylinder 5 is sandwiched between the baffle 1 and the water injection head 3 . The baffle 1 is an arc-shaped plate protruding from the inner wall of the connecting pipe 7 and matched with the connecting pipe 7 , and the inner surface of the baffle 1 and the inner surface of the connecting pipe 7 transition smoothly . The setting of the connecting pipe 7 has the following two situations: one end of the connecting pipe 7 is fixed with the water injection end 3 of the water injection hose 4, and the other end of the connecting pipe 7 is fixed with the plugg...

Embodiment 3

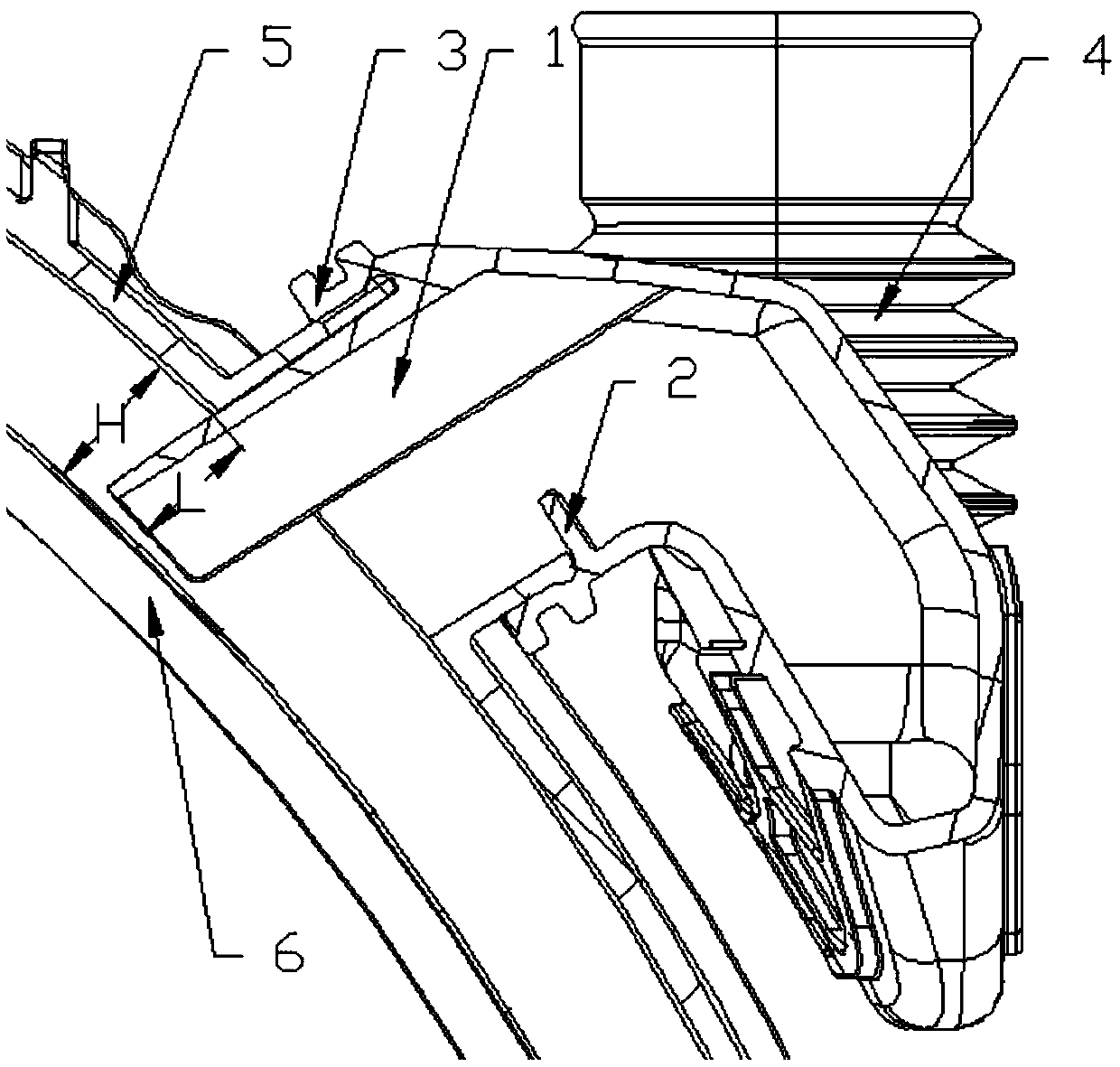

[0053] Such as Figure 1 to Figure 5 As shown, in this embodiment, an anti-overflow device for the water injection port of the drum, the anti-overflow device includes a baffle plate 1, and the baffle plate 1 is installed at the water injection port along the outer cylinder 5 to the inner cylinder 6, The water flow is prevented from flowing back into the water injection port with the high-speed operation of the inner cylinder 6 . According to the principle of fluid mechanics, when the fluid passes through the baffle plate 1 , a diversion flow will be generated to bypass the water injection port and slow down in the region of the water injection port to prevent backflow.

[0054] The ratio L / H of the length L of the baffle plate 1 protruding into the outer cylinder and the distance H between the inner and outer cylinders at the water injection port is greater than 0 and less than 1, preferably between 0.3 and 0.85. The maximum linear width W of the baffle 1 is greater than or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com