Novel concept pot

A new concept, pot lid technology, applied in multi-unit cooking utensils, overflow prevention, cooking utensil lids, etc., can solve problems such as defective overflow prevention function, inability to use steamer, and failure to solve the problem of lid opening and closing. Ideal overflow effect, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

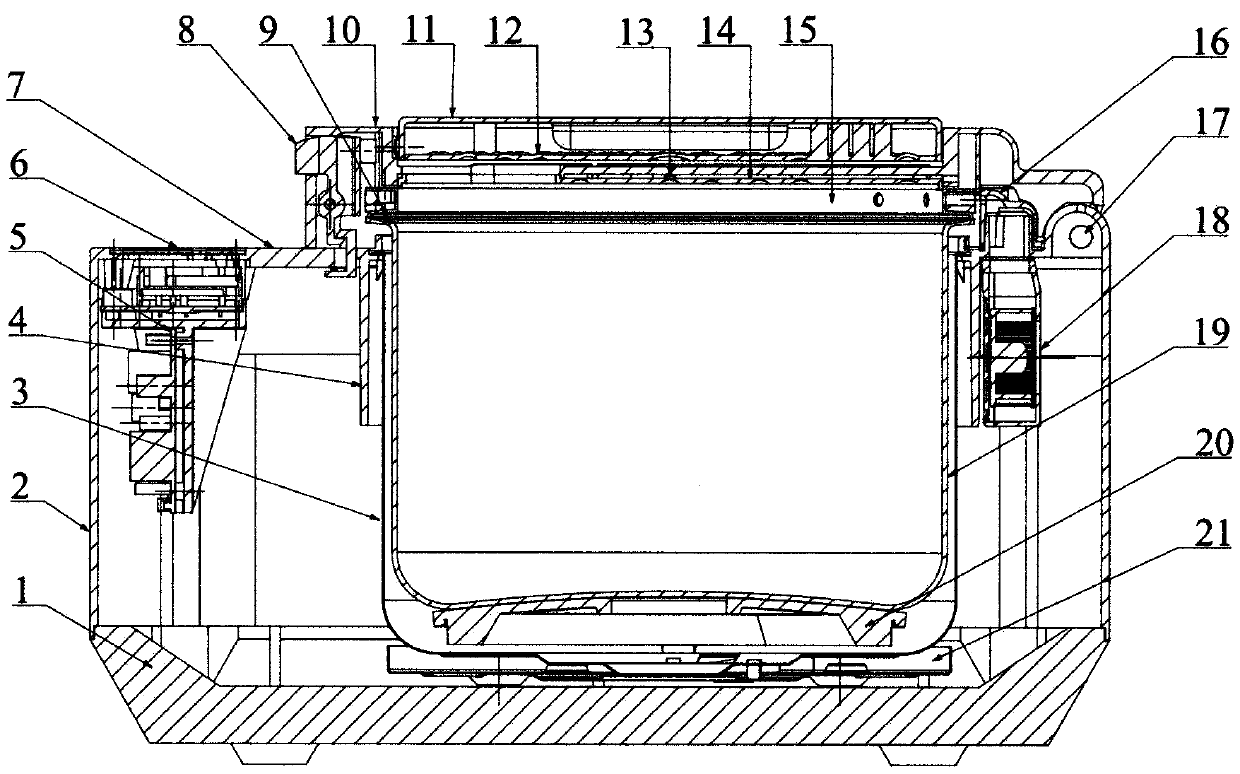

[0087] figure 1 It is a sectional view of the new concept pot.

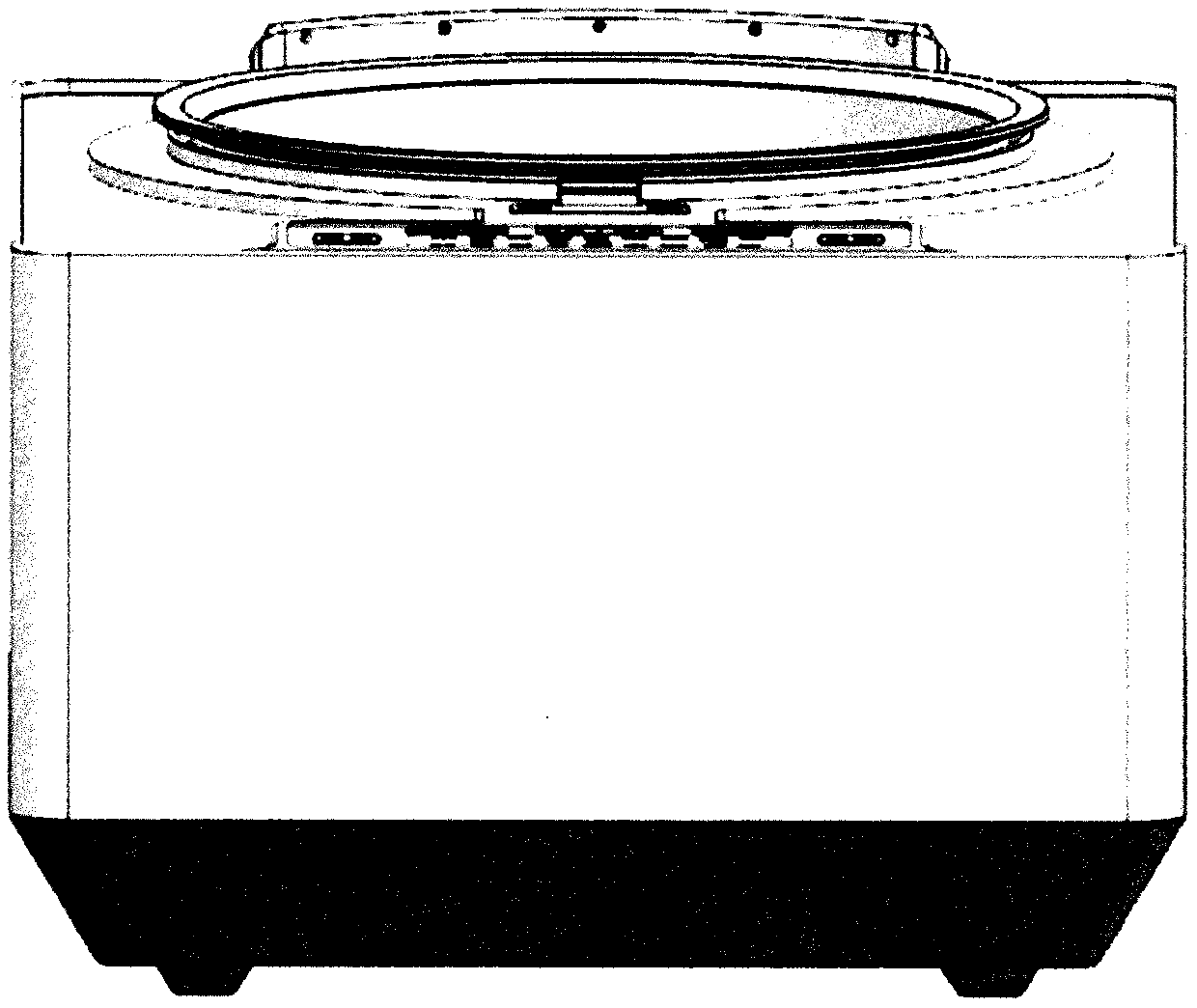

[0088] figure 2 It is the cuboid casing of the new concept pot body, the upper end surface of the cuboid casing is a pot platform, an operation panel is set in the center of the front of the pan platform, and a pot cover switch is set at the rear of the operation panel to buckle;

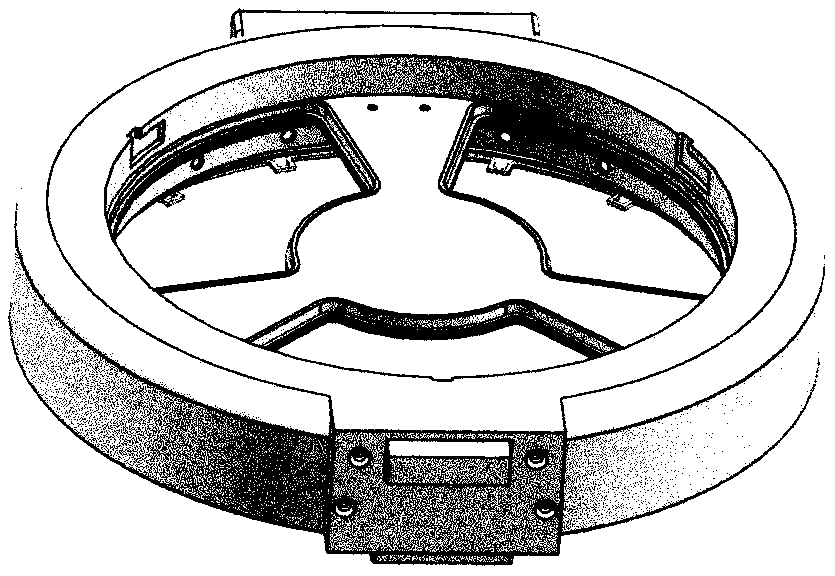

[0089] A circular hollow window is set behind the button of the lid switch; an outer pot is set in the circular hollow window; an inner pot is set on the mouth of the outer pot; the outer pot and the inner pot are clearance fit; Air ducts are set on the edge of the rear end of the pot;

[0090] Below the pot platform, a blower fan is set in the cavity between the outer pot and the casing of the pot body; the air duct air inlet and the fan air outlet on the pot platform are seamlessly conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com