Steam valve assembly and rice cooker provided with same

A steam valve and component technology, applied in the field of electric rice cookers, can solve the problems of poor foam breaking and backflow, low heat preservation and heating efficiency, poor anti-overflow performance, etc., so as to reduce steam discharge, increase foam breaking efficiency and anti-overflow performance. , the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

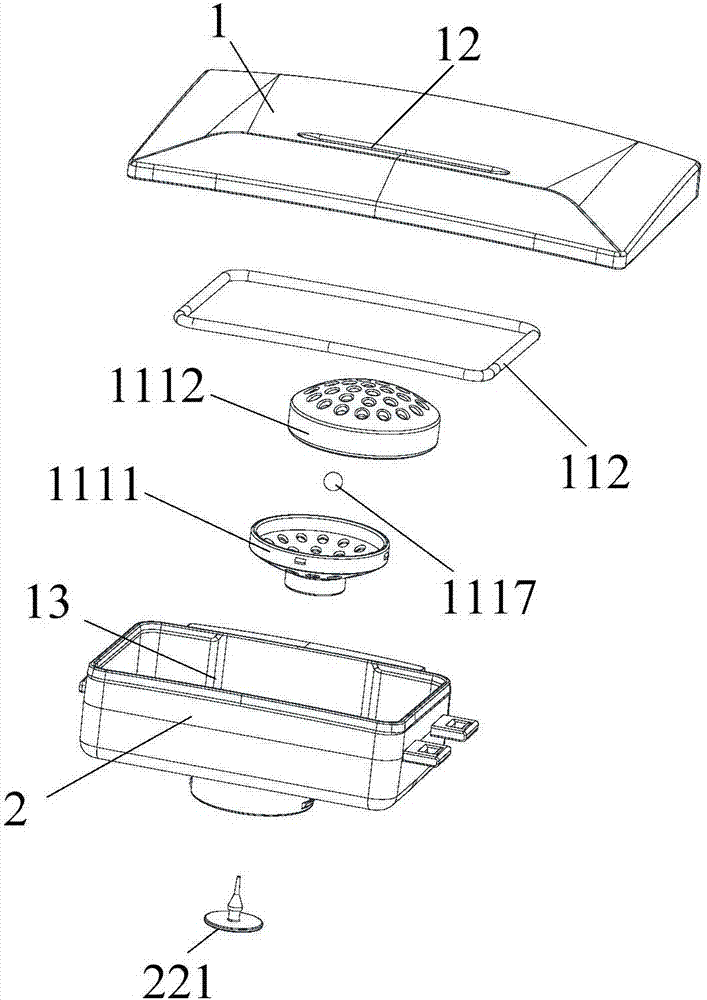

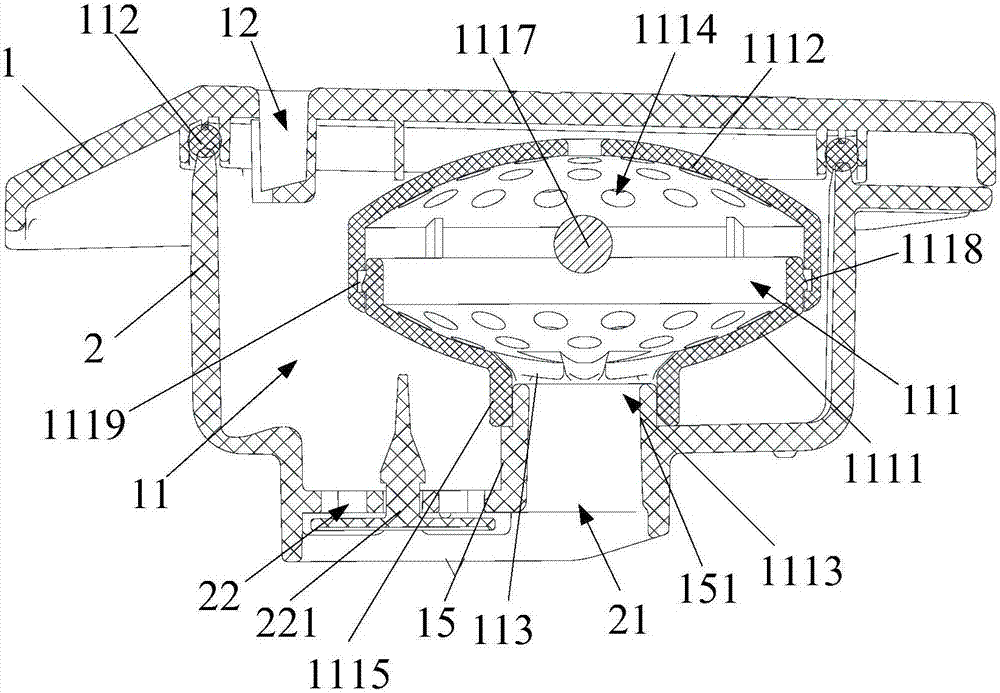

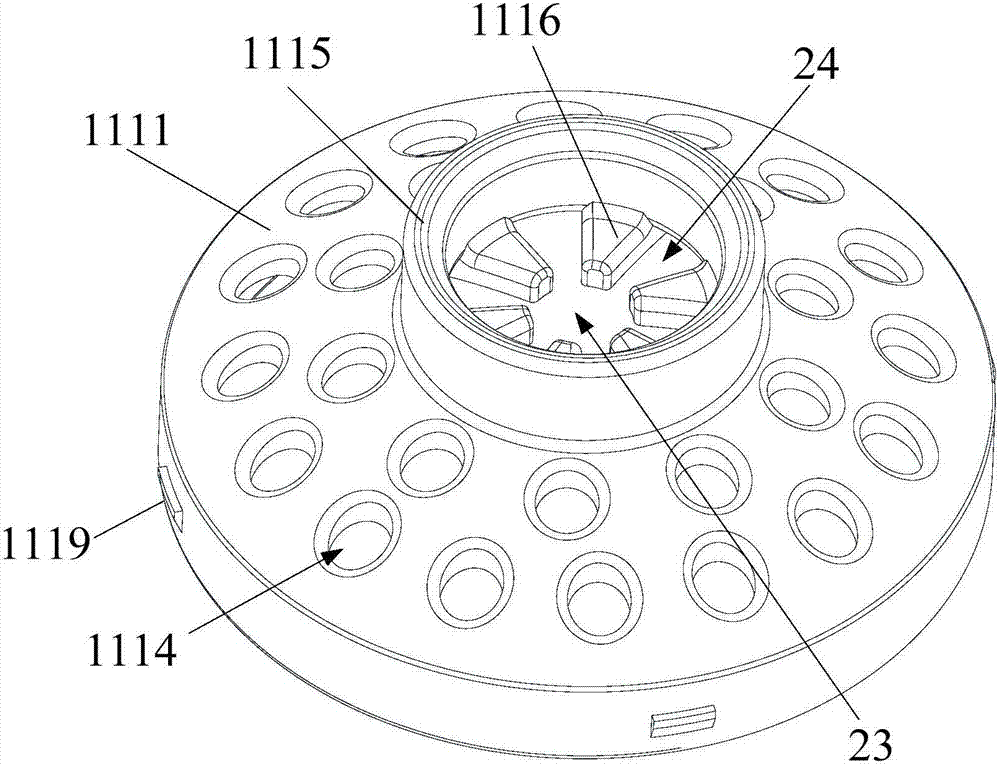

[0029] Such as figure 1 with figure 2As shown, the steam valve assembly provided in this embodiment includes a valve seat 2 and a valve cover 1, and the valve cover 1 covers the valve seat 2 to form a first cavity 11, and at the same time, the first cavity 11 There is also a second cavity 111 inside, the valve cover 1 is provided with a steam outlet 12 communicating with the first cavity 11, the valve seat 2 is provided with a steam inlet 21 and a return hole 22, the first The air inlet 1113 of the second cavity 111 is communicated with the steam inlet 21 through the steam channel; meanwhile, in the present embodiment, a bubble breaker 1117 is also provided in the second cavity 111, and the bubble breaker 1117 can be used in the steam Rolling in the second cavity 111 under action is used to break the foam entering the second cavity 111 . Specifically, the bubble breaker 1117 is a ball arranged in the second cavity 111, and the diameter of the ball is greater than or equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com