Underground powerhouse caverns for hydropower stations

A technology for hydropower stations and workshops, applied in the directions of hydropower stations, hydropower generation, underwater structures, etc., can solve the problems of unfavorable workshop work, traffic and long-term operation, damp workshops, and low drainage guarantee rate, etc. It is convenient for large-scale promotion, good waterproof performance and smooth drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention more clear, the specific content of the present invention will be described in detail below in conjunction with the accompanying drawings.

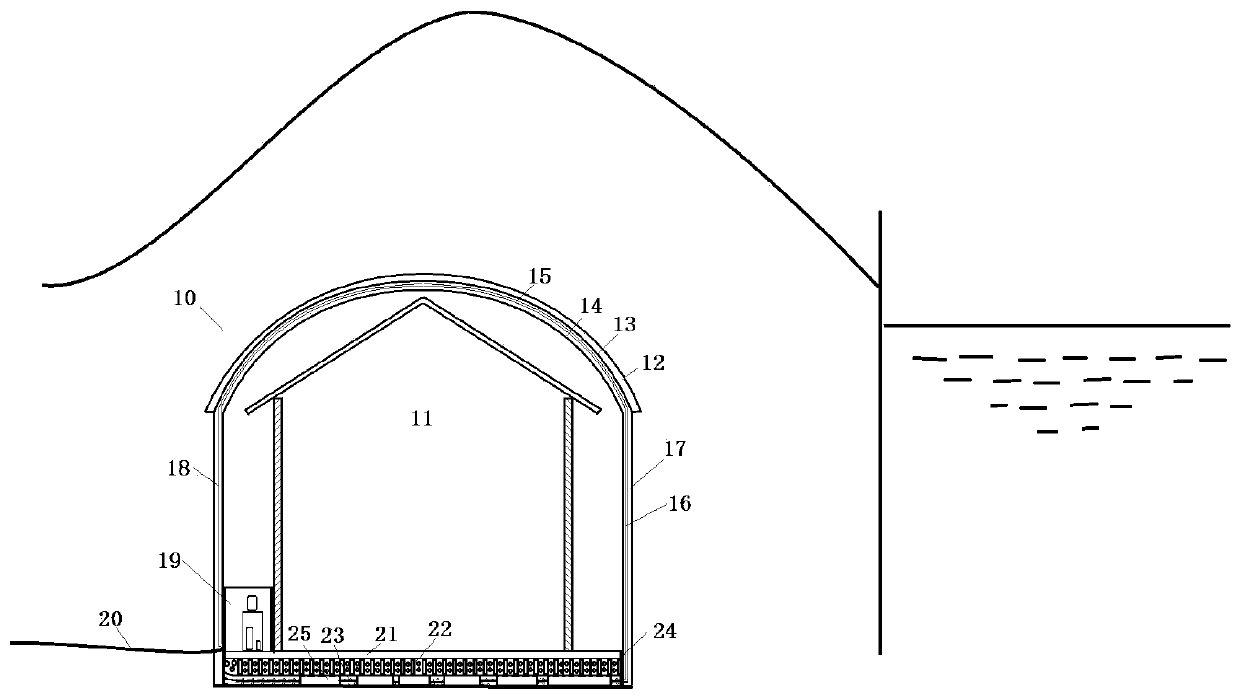

[0023] see figure 1 and 2 , shows the underground powerhouse cavern 10 for the hydropower station of the present invention, which is located in the mountain body.

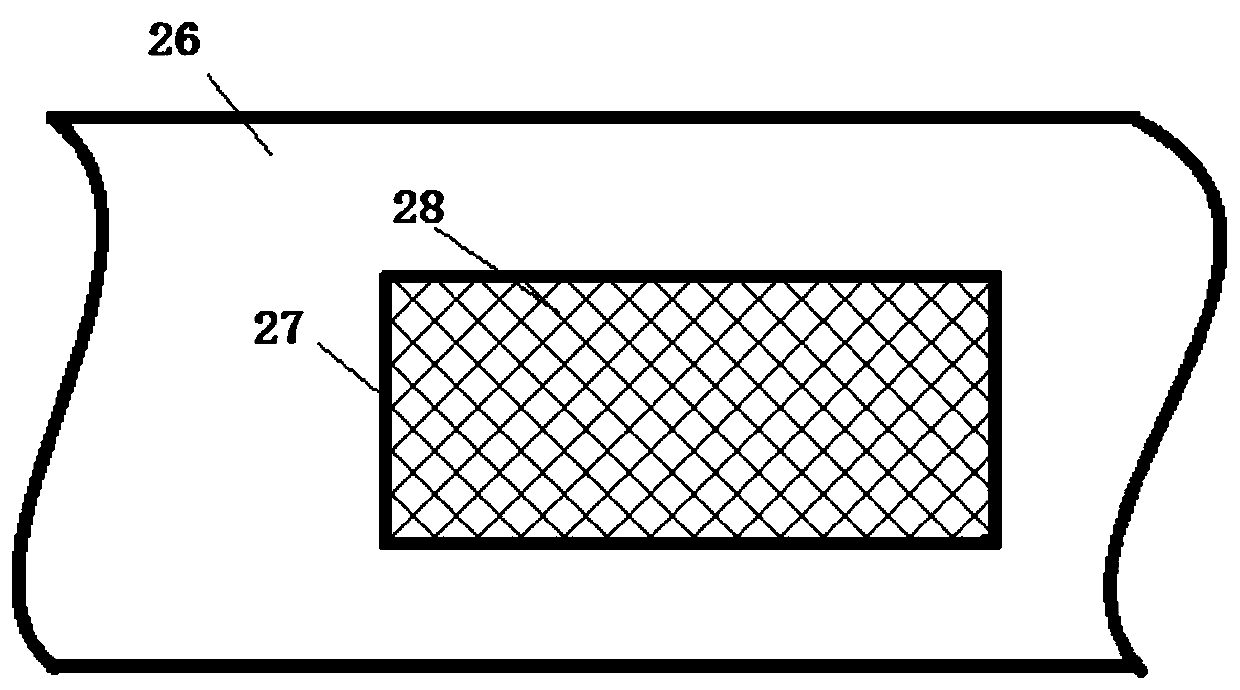

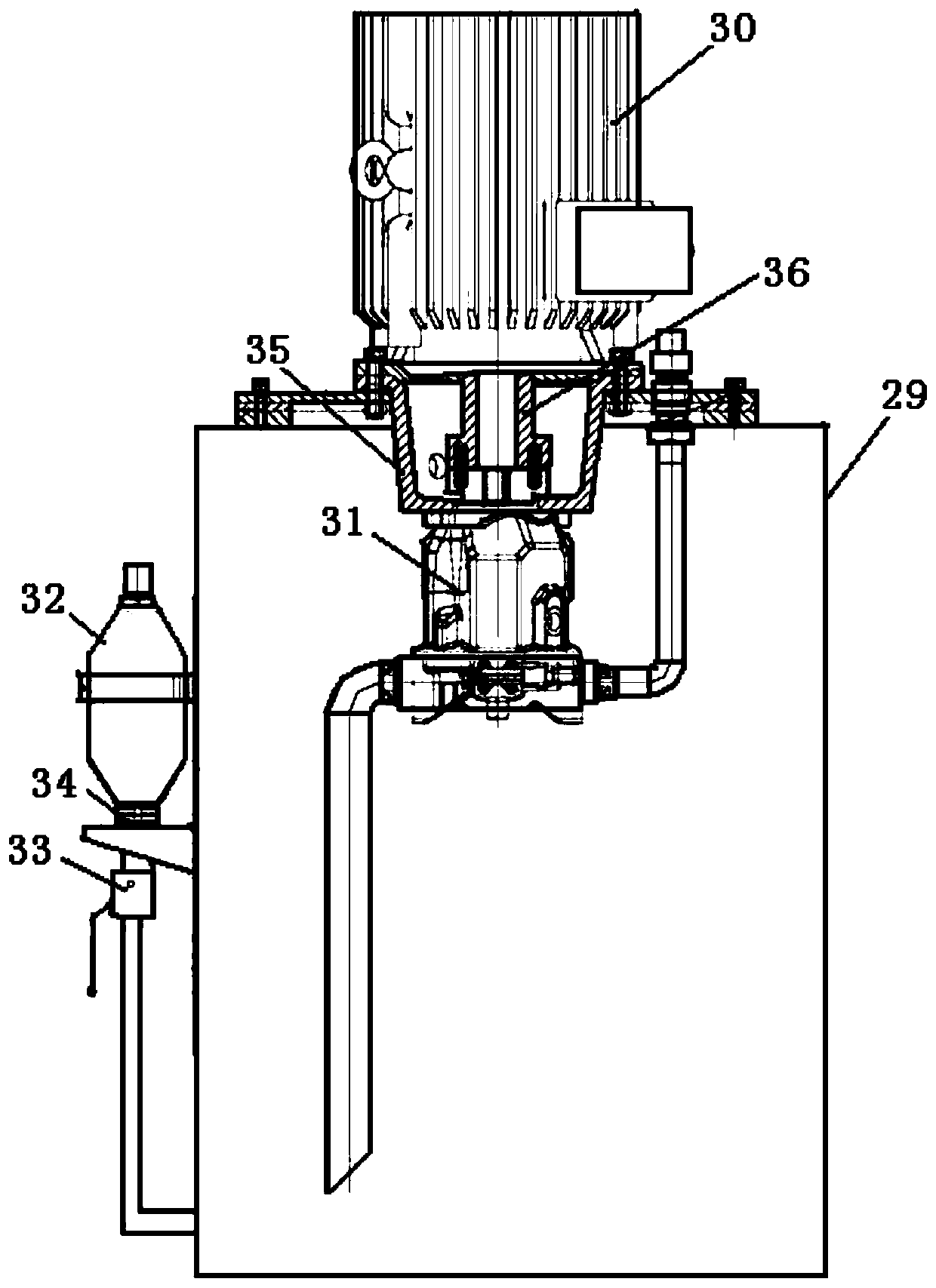

[0024] The underground powerhouse cavern 10 for the hydropower station includes a powerhouse structure 11 and a supporting structure, the powerhouse structure 11 is located in the supporting structure, and the supporting structure includes a top structure, an intermediate structure, a bottom structure and an integrated pumping station 19, so The top structure includes an arc-shaped water-resistant layer, and the arc-shaped water-resistant layer is divided into an outer sheath 12 and an inner sheath, and the outer sheath 12 and the inner sheath are both arc-shaped and the inner shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com