Device for triggering the gas spring

A gas spring and trigger technology, which is applied in the direction of springs, gas shock absorbers, spring/shock absorbers, etc., can solve the problems of impossible adjustment of gas spring speed, difficult trigger measurement, etc., to achieve compact structure, durable and reliable manufacturing , Reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] exist Figure 9 An exemplary use of the device 10 for activating a gas spring 1 for a seat 30 with an adjustable backrest 34 is shown schematically at a medium height. The backrest 34 is mounted rotatably about an axis of rotation 66 (arrow D) and is coupled to the gas spring 1 via a lever mechanism with a piston rod. In the inactive state of the device 10 , the gas spring 1 locks the swivel position of the backrest 34 via a lever mechanism. The device 10 is coupled via the actuating device 2 to the switching unit 32 and acts on the trigger of the gas spring. If the switching unit 32 is actuated, the device 10 acts on the trigger of the gas spring, whereby the rotational movement D of the backrest 34 is released. As soon as the switching unit 32 is deactivated, the gas spring 1 locks a further rotational movement D of the backrest 34 .

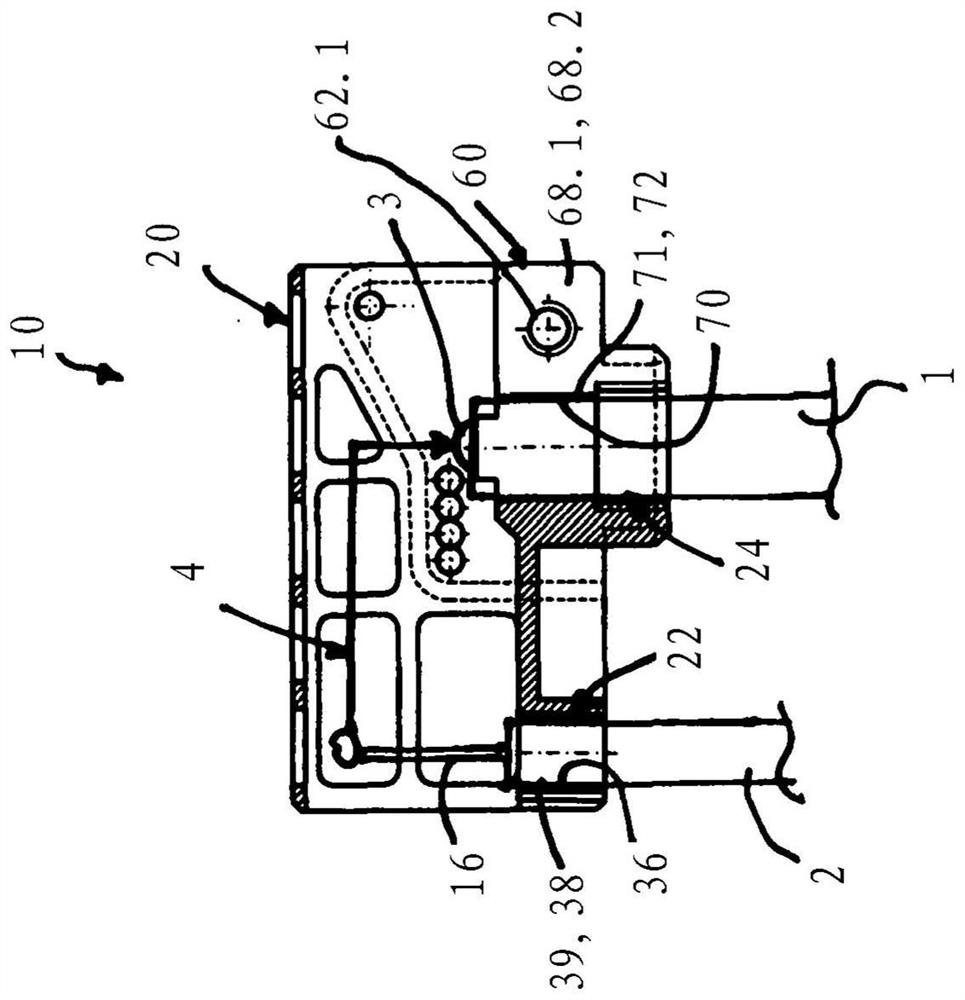

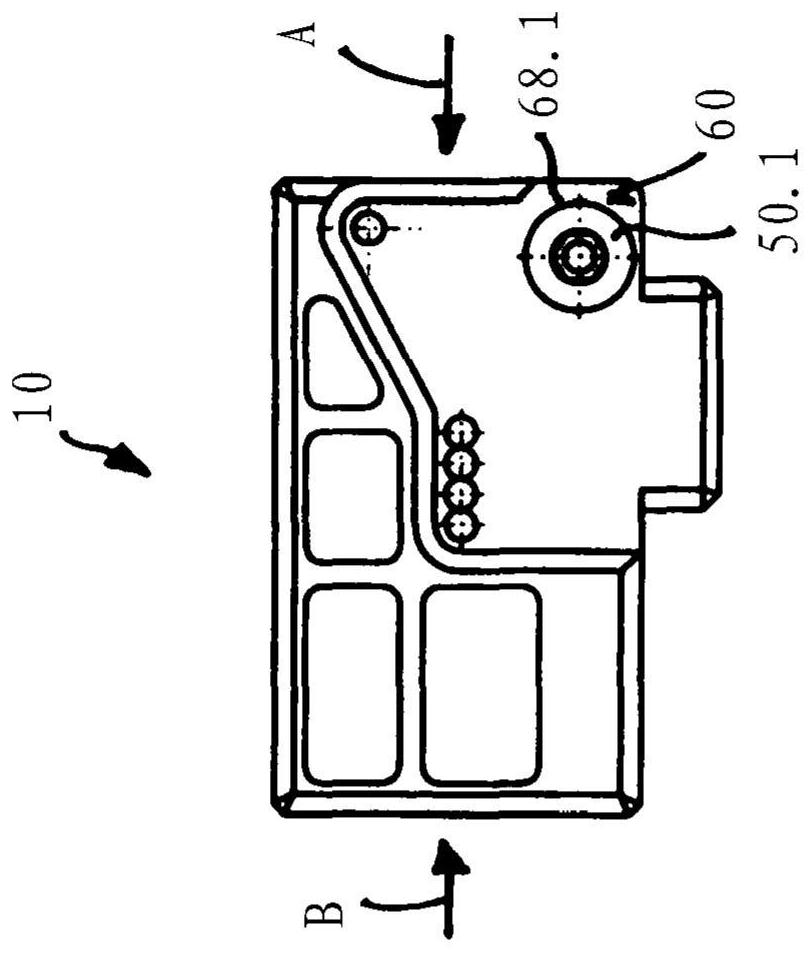

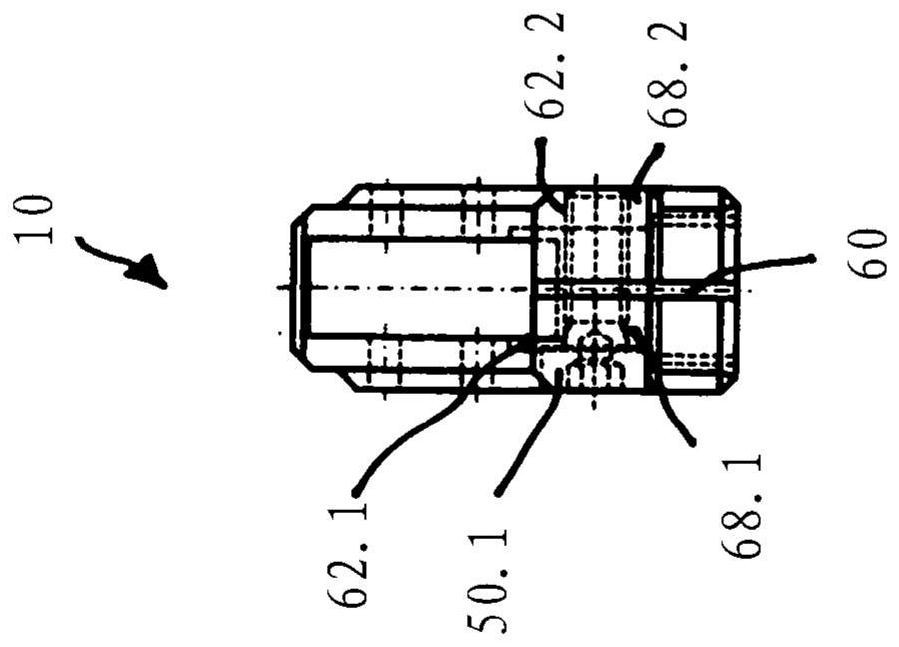

[0044] A first embodiment of a device 10 for triggering a gas spring is in Figures 1 to 4 is schematically shown in .

[0045] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com