A kind of electrostatic spraying equipment beneficial to spraying work

An electrostatic spraying and equipment technology, applied in electrostatic spraying devices, electrostatic heating/cooling devices, spraying devices, etc., can solve the problems of limited nozzle size, affecting work efficiency, and blockage of conveying pipelines, reducing the existence of particulate matter, improving Spraying efficiency, ensuring consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

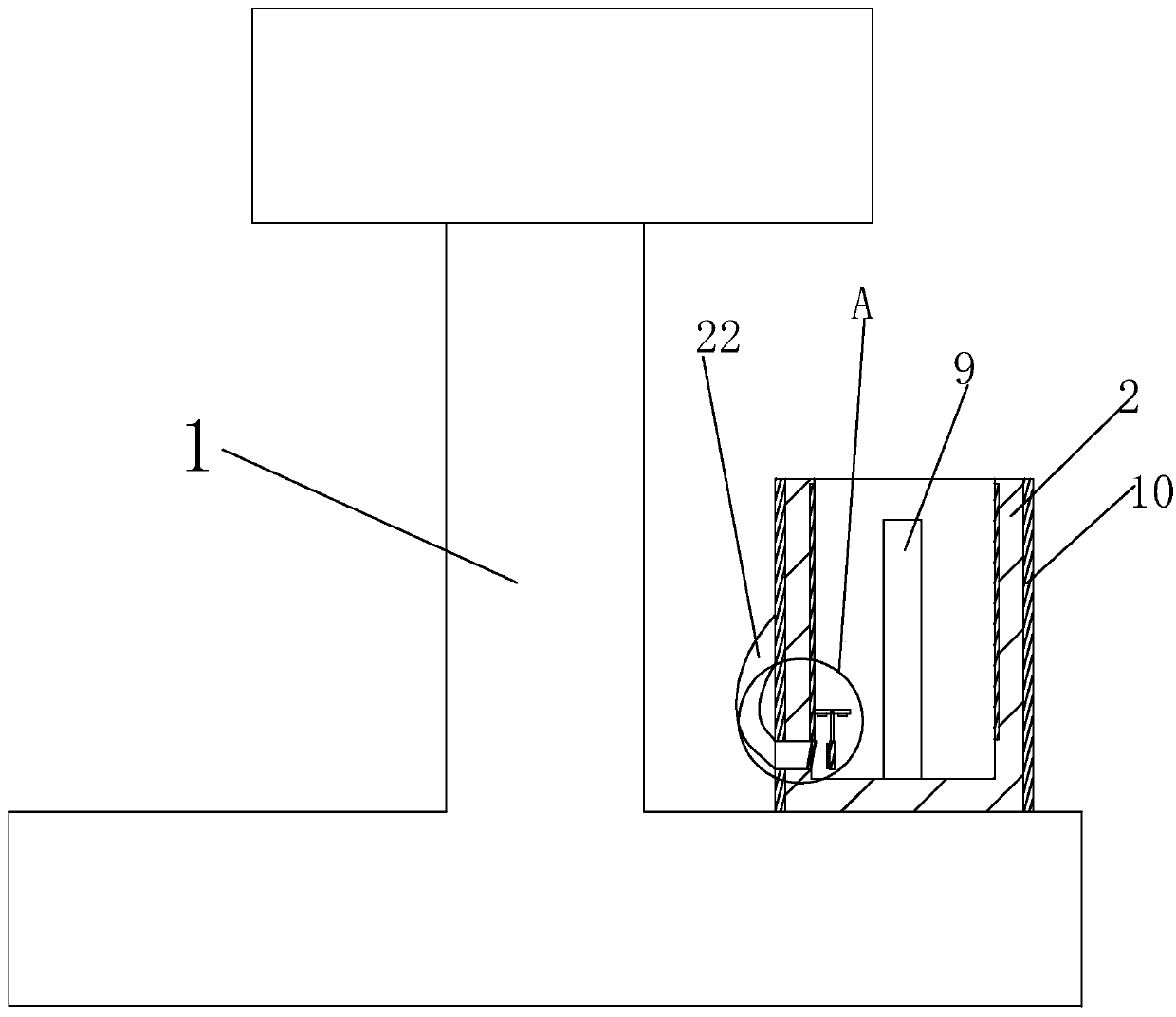

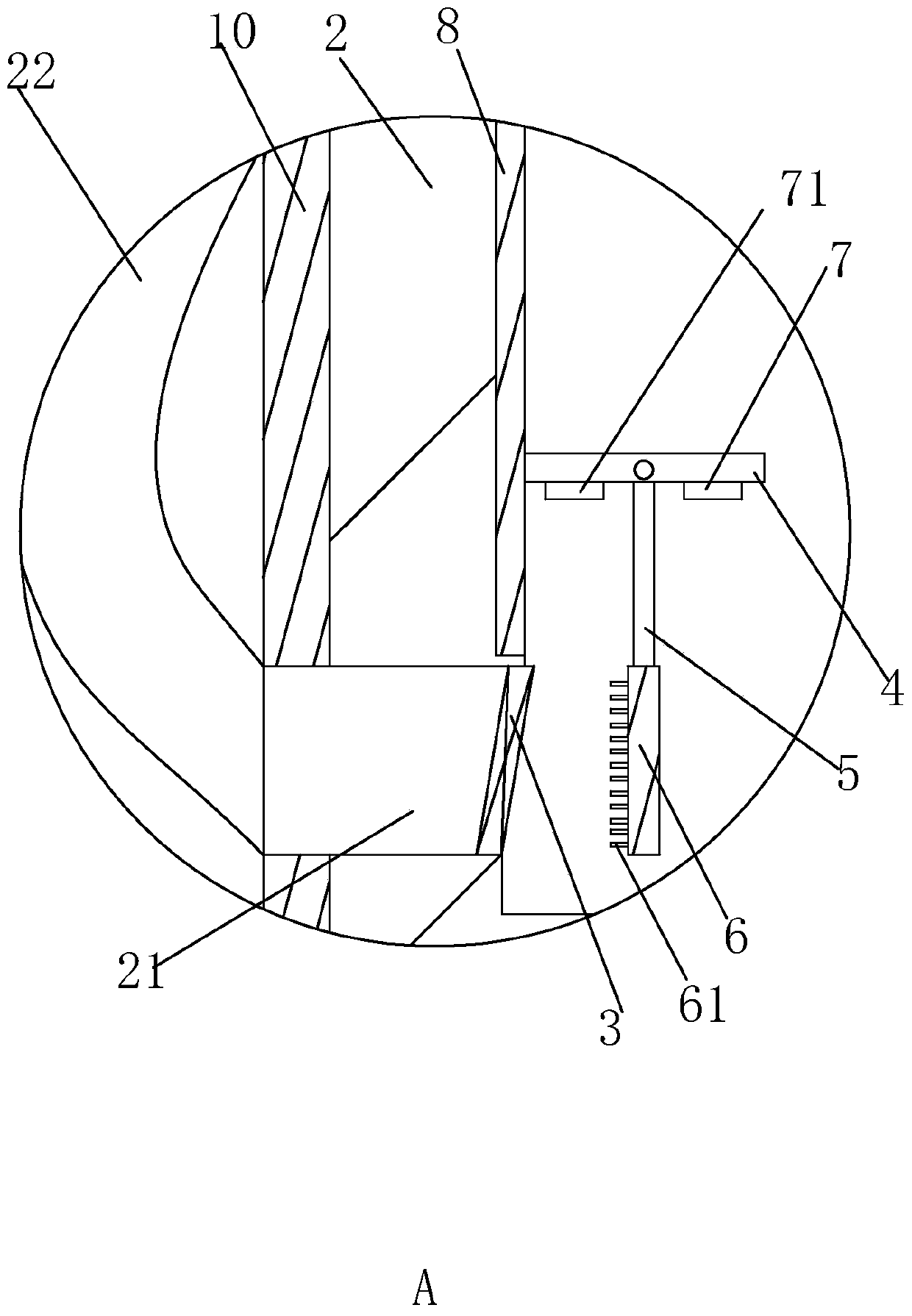

[0016] Embodiment: a kind of electrostatic spraying equipment that is beneficial to spraying work, as figure 1 and 2 As shown, the electrostatic spraying equipment includes a body 1, on which a storage tank 2 is fixed, and the side wall of the storage tank 2 is provided with a discharge port 21 connected to a delivery pipeline 22 near the bottom position, and the discharge An elastic filter screen 3 is fixedly and obliquely installed in the mouth 21. At this time, a connecting plate 4 is fixedly arranged on the inner wall of the storage tank 2 near the discharge port 21, and a connecting plate 4 is hinged to extend downward near the middle position. Connecting rod 5, the bottom of connecting rod 5 is fixedly provided with magnetic post 6, and the outer surface of magnetic post 6 is provided with a plurality of working needles 61, and is positioned at the two ends of connecting rod 5 on connecting plate 4 and is respectively fixed with pair of magnetic posts 6. Electromagnet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com