Cutter staggered double-face engraving machine

An engraving machine and double-sided technology, which is applied in the field of double-sided engraving machines, can solve the problems of affecting production efficiency and collision between upper and lower knives, and achieve the effects of reducing equipment cost, avoiding knife collision, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

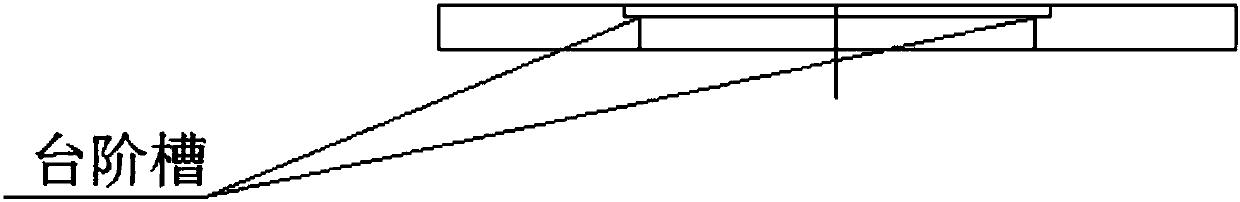

[0028] This embodiment needs to process the step groove used to fix the glass in the middle of the wooden door, such as Figure 1-2 As shown, the following double-sided engraving machines were used:

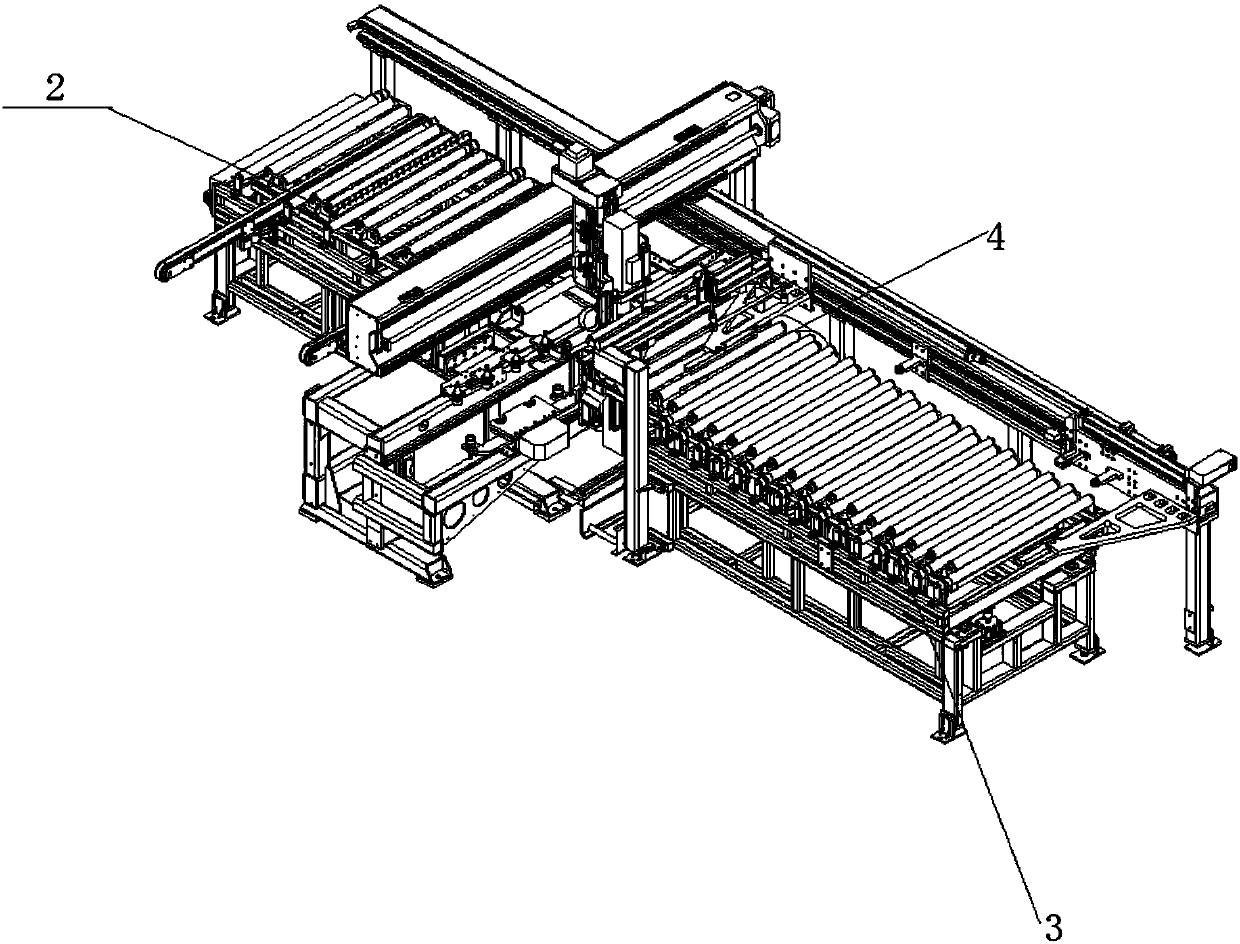

[0029] see Figure 3-Figure 6 , a double-sided engraving machine with cutter dislocation, comprising a feed table 2 and a discharge table 3, the sample feed table and the sample discharge table are arranged along the X axis, and there is a set between the sample feed table and the sample discharge table along the Y axis. The upper processing unit and the lower processing unit; the upper processing unit is located at the upper part of the Z axis, and the lower processing unit is located at the lower part of the Z axis; the respective Z-axis cutter heads on the upper and lower processing units are misaligned in the Y-axis direction during the cutting process; X axis is perpendicular to the Y axis, and the Z axis is perpendicular to the XOY plane.

[0030] In this embodiment, the ...

Embodiment 2

[0033] The processed workpiece of the present embodiment is likewise Figure 1-2 Wooden door shown with step-slot opening for glass.

[0034] see image 3 and Figure 7 , a double-sided engraving machine with tool dislocation, comprising a sample inlet 2 and a sample outlet 3, the sample inlet and the sample outlet are arranged along the X-axis, and there is a set between the sample inlet and the sample outlet along the Y-axis The upper processing unit and the lower processing unit; the upper processing unit is located at the upper part of the Z axis, and the lower processing unit is located at the lower part of the Z axis; the respective Z-axis cutter heads on the upper and lower processing units are misaligned in the Y-axis direction during the cutting process; X axis is perpendicular to the Y axis, and the Z axis is perpendicular to the XOY plane.

[0035] Such as Figure 7 As shown, the upper processing unit and the lower processing unit adopt the same Y-axis power sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com