Walking mechanism and trackless multifunctional automatic installation machine using walking mechanism

A technology of automatic installation and running mechanism, which is applied in the direction of transportation and packaging, ship parts, ships, etc. It can solve the problems of affecting traffic and other operations, inconvenient operation and storage, and large body, and achieves light weight, flexible and convenient use, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

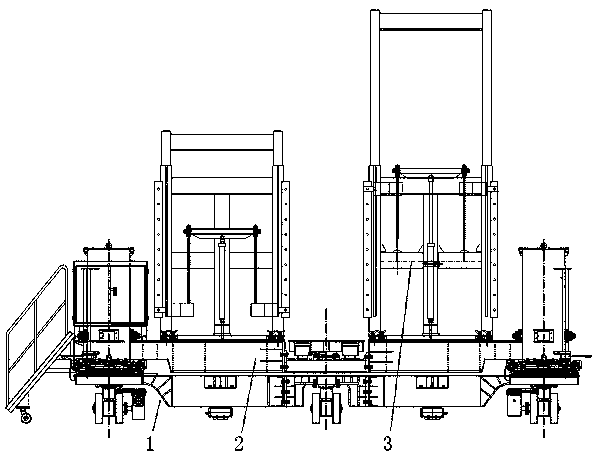

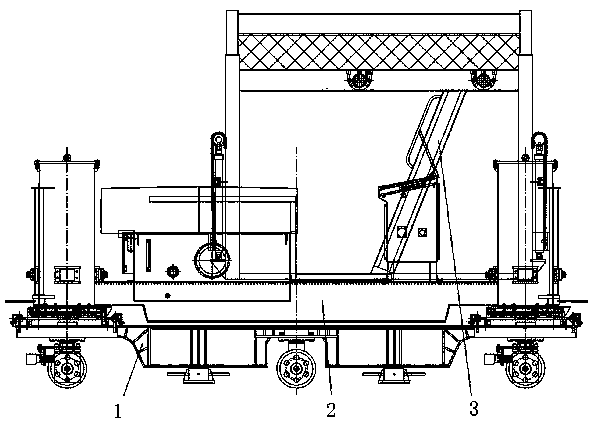

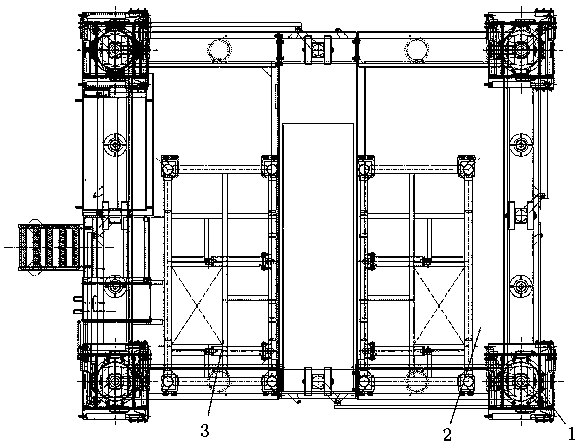

[0046] like Figure 4-8 As shown, the present invention is a kind of running mechanism, and it comprises a plurality of traveling wheel groups 12, jacking oil cylinder 13, jacking fixture 14 that are installed on frame body 11 lower ends, and described traveling wheel group 12 includes being installed on axle 121, Wheel 122, described wheel 122 is installed on wheel shaft 121 both sides, and described wheel shaft 121 is equipped with driving device, and driving device adopts hydraulic motor 125, is connected with speed reducer 124 on the hydraulic motor, and hydraulic motor 125 drives wheel 122 to walk, and walking wheel Group 12 can be made up of active travel wheel group, driven travel wheel group, and driven action wheel group has no drive device, can add a plurality of steel wheel bearings under the vehicle frame, and the middle part of described wheel axle 121 is installed on the main shaft 15 lower end, both axes Vertically, the main shaft 15 is a vertical shaft, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com