A kind of recovery and purification process of alkaline magenta mother liquor

A mother liquor recovery and process technology, applied in organic dyes, chemical instruments and methods, diaryl/triaryl methane dyes, etc., can solve the problems of long production process, environmental hazards, and high pollutant discharge, and achieve efficient purification , Efficient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

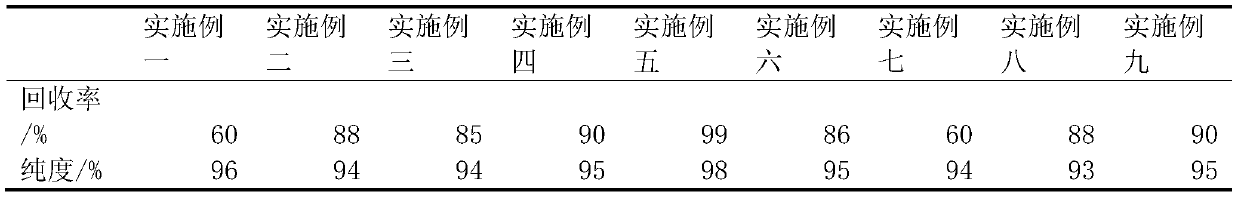

Examples

Embodiment 1

[0028] Embodiment one: the process of recovering and purifying the mother liquor of alkaline magenta comprises the following steps:

[0029] S1. Adjustment process:

[0030] Add a certain amount of water to the alkaline magenta mother liquor to make the mass concentration of alkaline magenta reach 55% to 65%, stir under the condition of aeration, after stirring for 10 minutes, stop the aeration and stirring, and adjust the temperature to 25 ℃, continue to stir, and slowly add liquid caustic soda, so that the pH value of the solution reaches 2-3, stop stirring after the chroma reaches 15%;

[0031] S2, neutralization process:

[0032] Slowly add liquid caustic soda to the solution obtained in S1 while stirring, so that the pH value of the solution reaches 4 to 5, and the color of the solution is light purple, stop stirring, and obtain the neutralized mother liquor;

[0033] S3, color base preparation process:

[0034] Add liquid caustic soda to the neutralized mother liquor ...

Embodiment 2

[0042] The difference from Example 1 is that in S1, when the chromaticity reaches 15% and remains unchanged for 1 hour, the stirring is stopped. If the color changes within 1 hour, liquid caustic soda is added dropwise to adjust until the chromaticity remains constant for 1 hour. Change.

Embodiment 3

[0044] The difference from Example 1 is that the stirring is stopped after the color of the solution in S2 remains unchanged for 20 minutes, and if the color changes within 20 minutes, liquid caustic soda is added dropwise to adjust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com