Spiral rib lining connecting piece for carat tubes

A technology of connectors and spiral ribs, which is applied in the field of spiral rib lining connectors, can solve the problems of poor appearance, low strength, and poor quality of products, and achieve the effects of good connection effect, fast connection positioning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

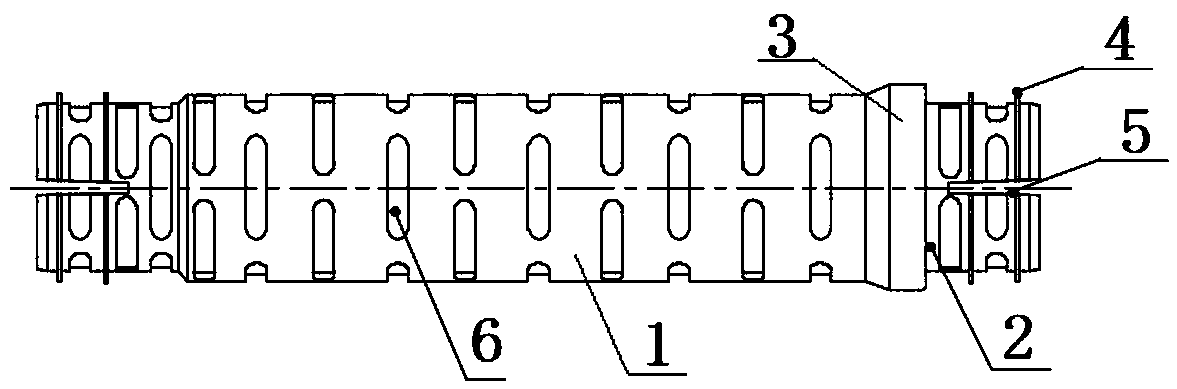

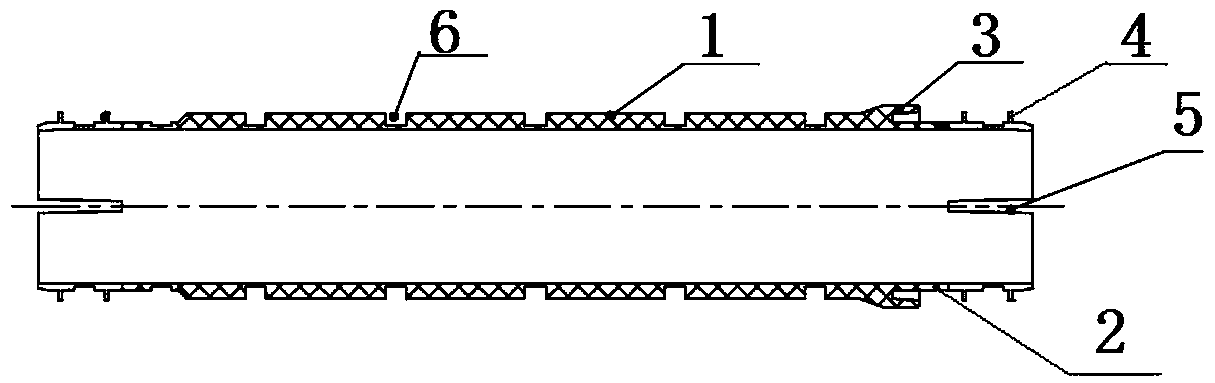

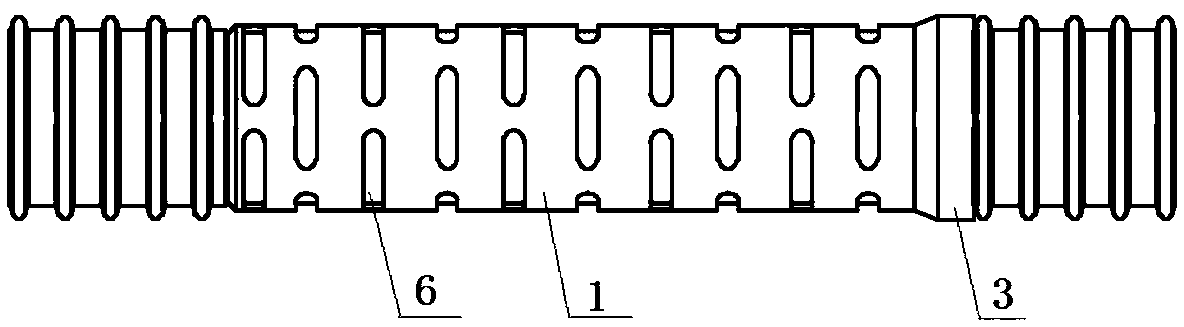

[0023] Such as Figure 1 to Figure 4 As shown, a spiral rib lining connector of a carat tube, which includes a transition body 1, the two ends of the transition body 1 are provided with a socket 2, and the socket 2 at one end of the transition body 1 is provided with a receiving groove 3, The outer wall of the socket 2 is provided with ribs 4, and the connecting piece uses the sockets 2 at both ends to connect the inner bellows of the spiral ribs on the periphery of the two carat tubes.

[0024] The lining connector is composed of two parts, the transition body 1 and the socket 2. It is connected to the lining bellows of the spiral rib through the rib 4 of the socket 2 and the receiving groove 3. After the position is limited, it is quickly positioned and connected to the lining pipe. . The convex rib 4 makes the connection between the socket 2 and the lining bellows of the spiral rib increase the frictional force, and the convex rib 4 cooperates with the receiving groove 3 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap