Gas turbine combustor and method of use thereof

A gas turbine and combustion chamber technology, applied in the direction of combustion methods, combustion chambers, continuous combustion chambers, etc., can solve the problems of difficult ignition of low calorific value fuels, easy extinguishment of combustion chambers, and easy extinguishment, so as to facilitate ignition and full combustion, avoid Effect of tempering and high combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

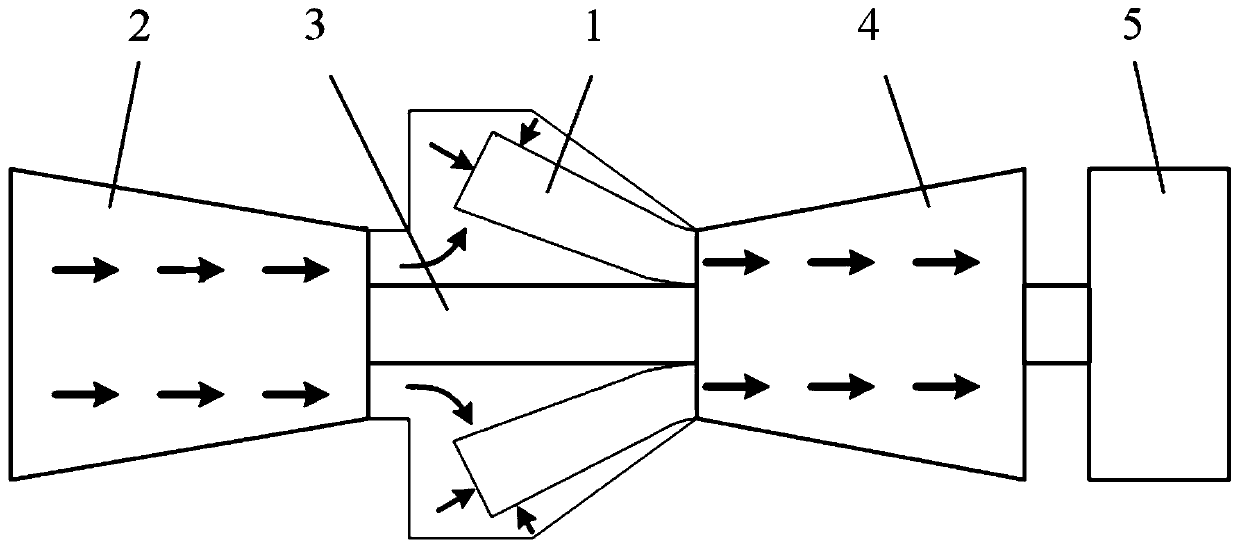

[0073] figure 1 A schematic block diagram of a gas turbine according to an embodiment of the present invention is shown, showing gas flow paths. Such as figure 1 As shown, the gas turbine may include a compressor 2 , a combustor 1 and a turbine 4 . The air is compressed into high-pressure gas by the compressor 2, and then the high-pressure gas is mixed with fuel in the combustion chamber 1 to participate in combustion to form high-pressure and high-speed gas. Finally, the high-pressure and high-speed gas drives the turbine 4 to rotate and generate power, and supplies power to the load 5 . A connecting shaft 3 is arranged between the compressor 2 and the turbine 4 , and the connecting shaft 3 is used to connect the compressor 2 and the turbine 4 together so as to realize the transmission connection between the turbine 4 and the compressor 2 .

[0074] Gas turbines in the prior art have the disadvantages that combustion chamber 1 is prone to flameout during low-load operation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com