Knock-on type wall insulation board continuity detection device and detection method

A technology of detection device and thermal insulation board, which is applied in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. Achieve the effect of reducing transmission and diffusion, improving accuracy, and avoiding sound diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

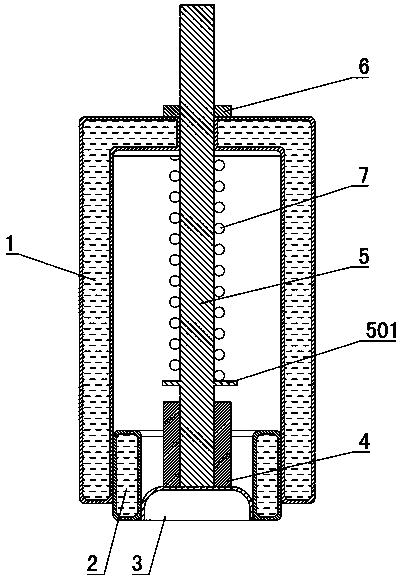

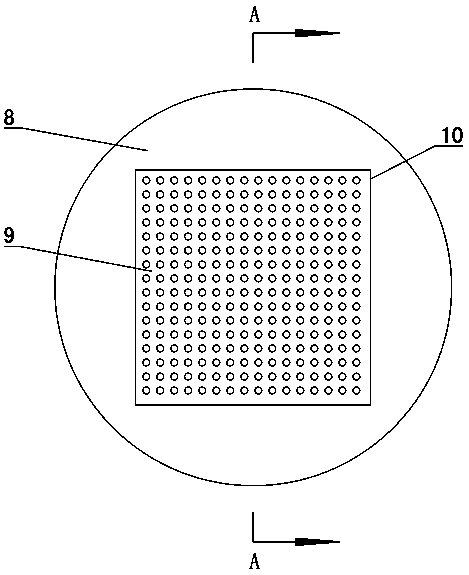

[0043] Such as figure 1 As shown: the outer cover 1 is a cylindrical shape with a closed upper end, the side wall of the outer cover 1 is provided with an annular cavity coaxially arranged with the outer cover 1, and the top of the outer cover 1 is also provided with a disc-shaped cavity coaxially arranged with the outer cover 1, thereby Form the sound-insulating cavity of the outer cover, and the sound-insulating cavity of the outer cover is filled with liquid. In this embodiment, the liquid filled in the sound-insulating cavity of the outer cover is water, so that the sound emitted between the percussion module and the sounding body 3 can be isolated, and the diffusion of the sound can be reduced. Improve detection accuracy. The elimination of noise can also be realized by arranging sound-proof cotton on the outer wall of the outer cover 1 .

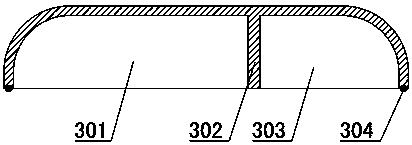

[0044] The sounding body 3 is a cylinder with a closed upper end, the sounding body 3 is coaxially arranged with the outer cover 1, ...

Embodiment 2

[0070] Such as Figure 5 As shown: the difference between embodiment 2 and embodiment 1 is that: the outer cover 1 is not provided with an outer cover sound-proof chamber, which reduces the weight of the outer cover 1, thereby greatly reducing the weight of the entire device.

Embodiment 3

[0072] Such as Figure 6 Shown: the difference between embodiment 3 and embodiment 1 is: sound insulation ring 2 is not set between sounding body 3 and outer cover 1, the outer diameter of sounding body 3 is slightly smaller than the inner diameter of outer cover 1, and the top of sounding body 3 stretches into outer cover within 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com