A kind of tea drying rack

A technology for withering racks and drying greens, applied in the field of tea withering racks, can solve the problems of high speed, difficulty in meeting multi-form markets, etc., and achieve the effects of improving management and speeding up the withering process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

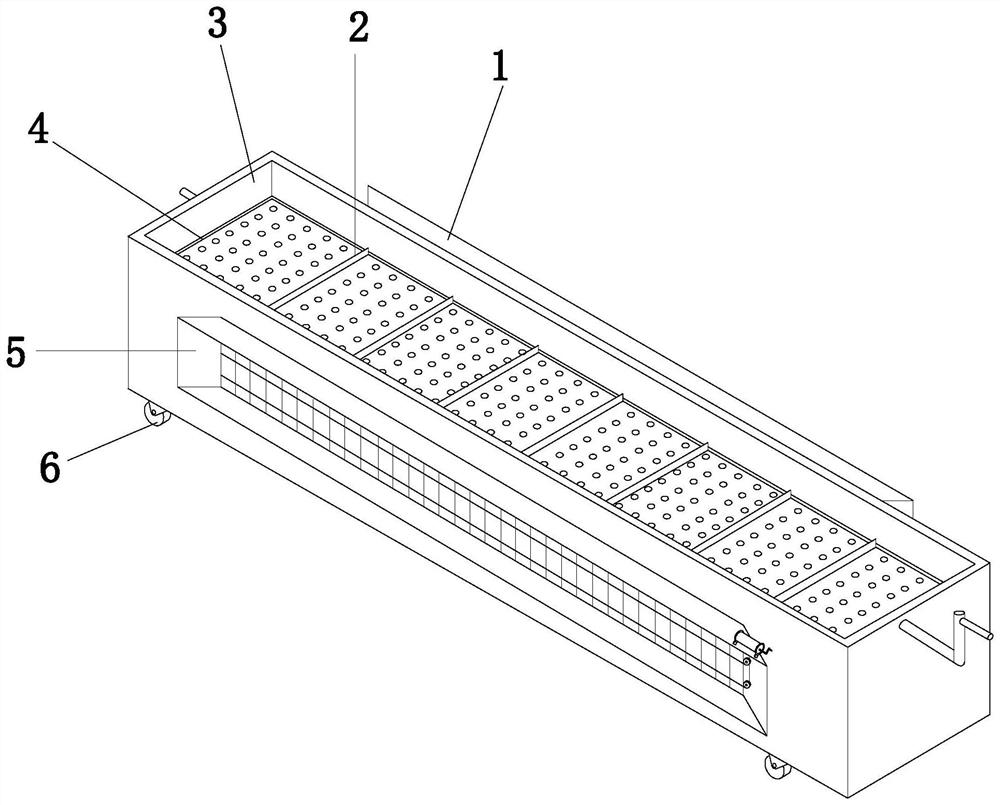

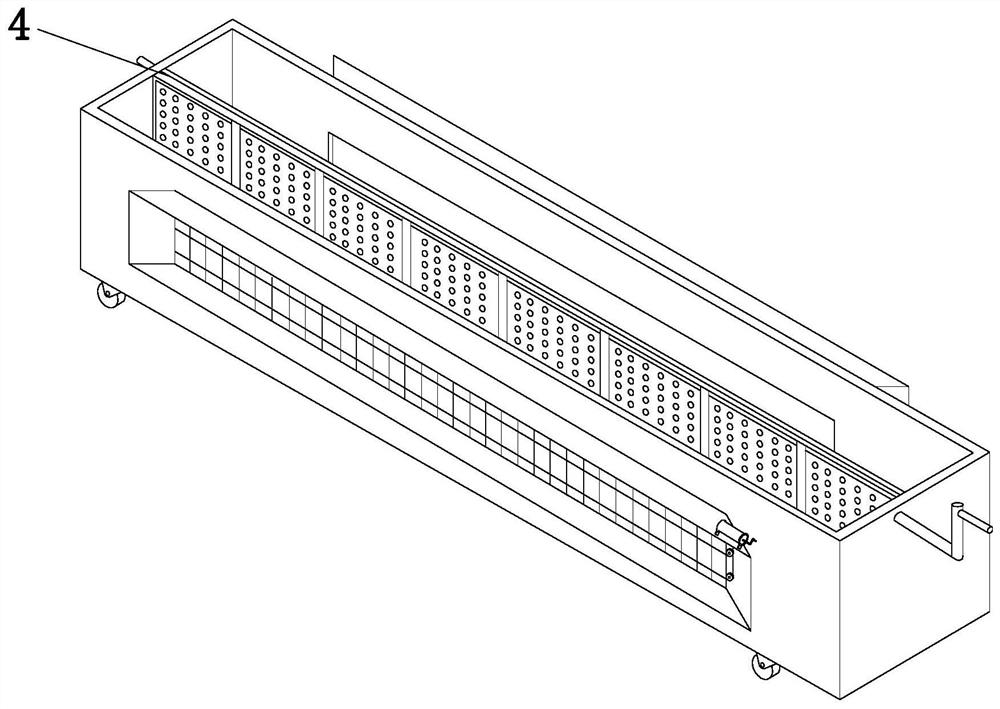

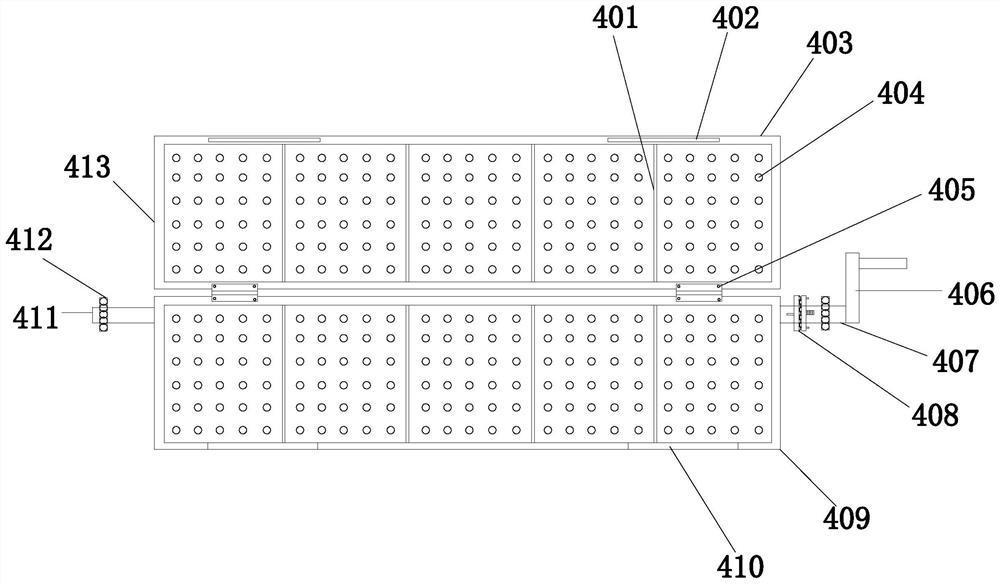

[0028] see Figure 1-Figure 5, the present invention provides a tea drying and green withering rack, the structure of which includes an airflow guide cover 1, a withering rack partition 2, a frame 3, a withering rack 4, an air guiding adjustment cover 5, and casters 6; the frame 3 is a rectangular structure And the bottom is provided with four casters 6 evenly and equidistantly. The casters 6 are fixed on the bottom of the frame 3 by screws. The air guide adjustment cover 5 is buckled and fixed on the frame 3, the airflow guide cover 1 and the frame 3 are welded together, the inner center of the frame 3 is provided with a withering frame 4, and the withering frame 4 and the frame 3 adopt Clearance fit, the said withering frame 4 is provided with withering frame partitions 2 side by side equidistantly, and the described withering frame partition 2 and the withering frame 4 match; the described withering frame 4 is fixed by the partition plate slot 401, bar 402, air circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com