A rotatable inner hole laser cladding device

A technology of laser cladding and inner hole, which is applied in the direction of metal material coating process, coating, etc., can solve problems such as non-rotation, achieve the effect of solving the problem of shaking, expanding the scope of application, and broadening the application prospect of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

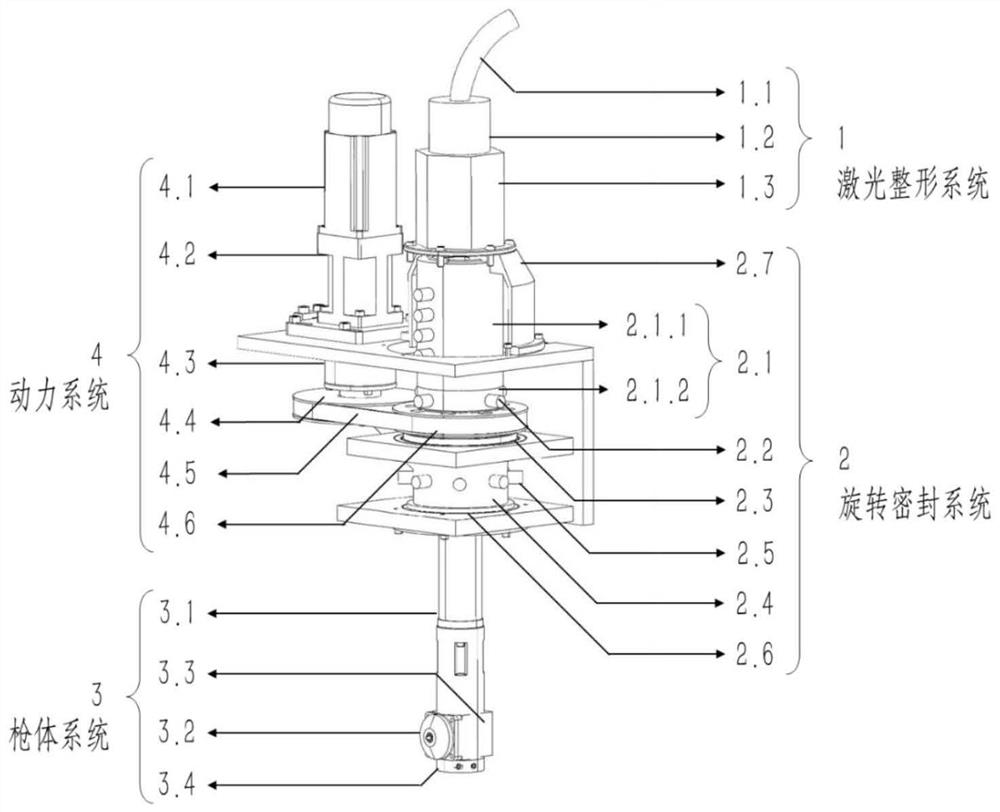

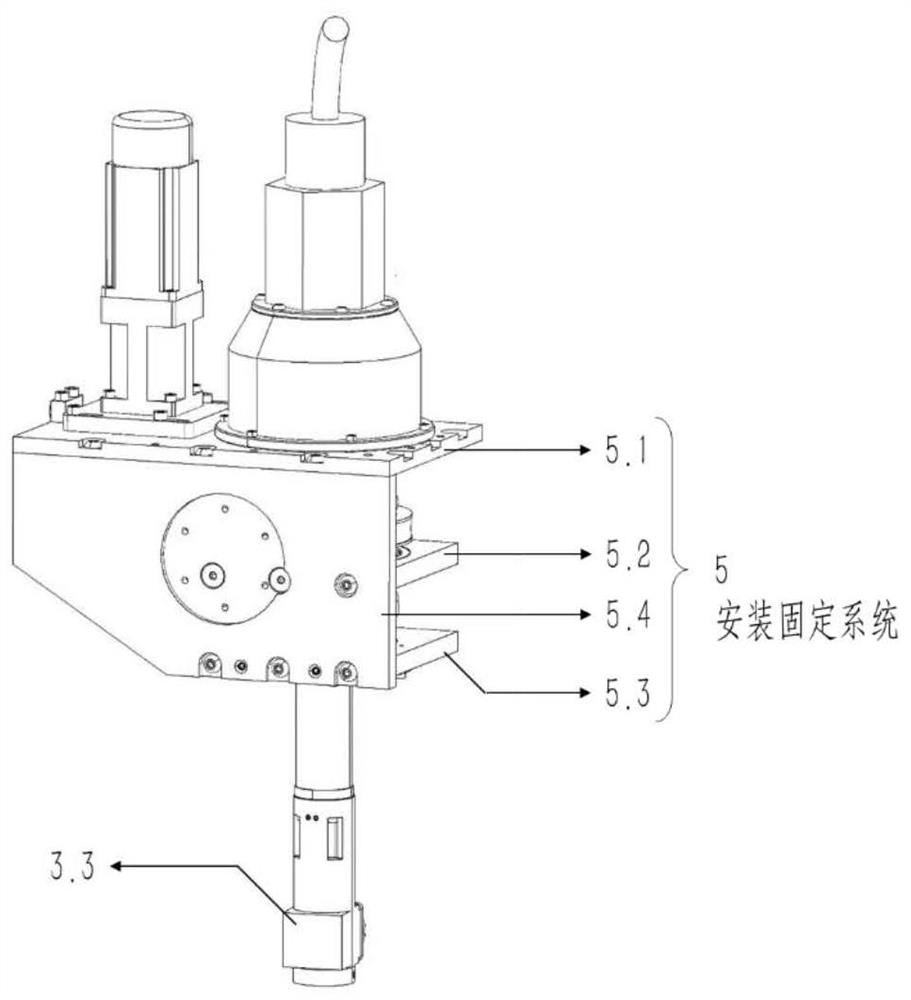

[0033] like Figure 1-Figure 4 Shown: a rotatable inner hole laser cladding device and method, including a laser shaping system 1, a rotary sealing system 2, a cladding gun body system 3, a power system 4 and an installation and fixing system 5.

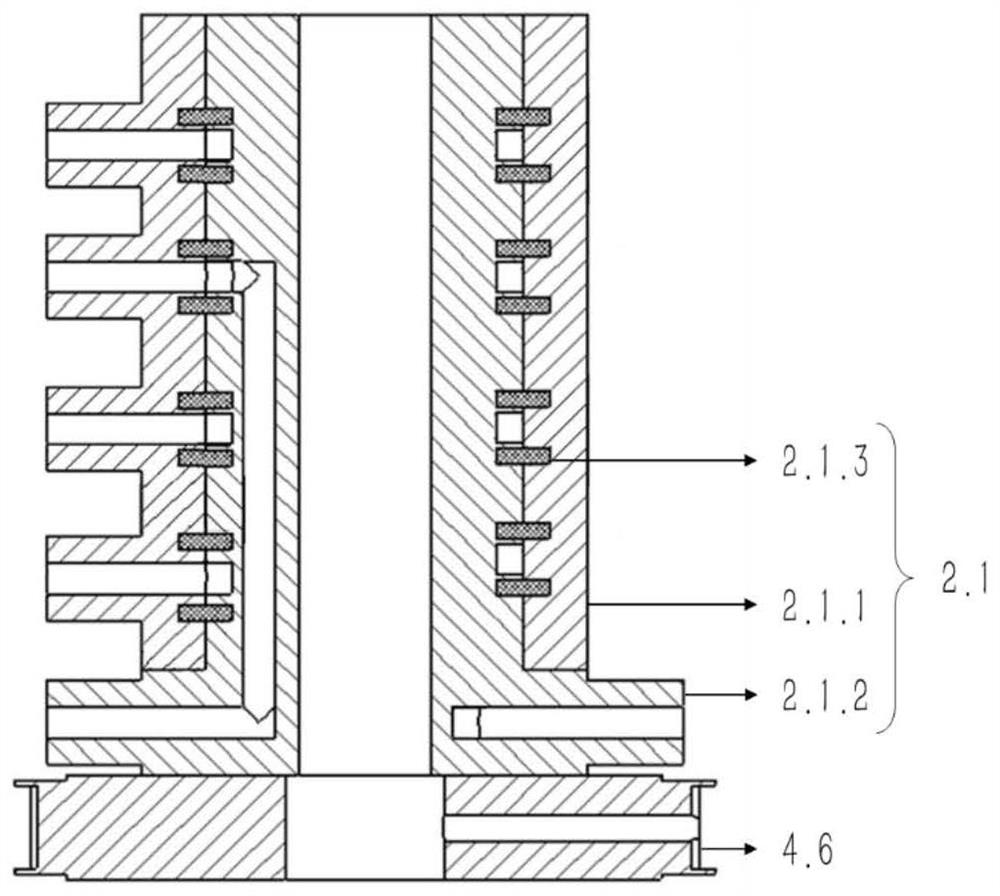

[0034] further, as figure 1 As shown, the laser fiber 1.1 is connected to the lens group 1.3 through the QBH connector 1.2. The lens group 1.3 can shape the Gaussian beam emitted by the fiber 1.1 into a collimated beam and propagate along the axis of the gun body. The lower end of the laser shaping system 1 is connected with the rotary sealing system 2, and the rotary sealing system 2 can realize the supply of water cooling, protective gas and powder required by the gun body system 3 in the rotating state.

[0035] further, as figure 1As shown, the lens group 1.3 is connected with the rotary sealing joint shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com