Assembling method of roller type overrun clutch

An overrunning clutch and assembly method technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of roller shedding, low success rate, and blockage, so as to ensure the stability and reliability of use, ensure the flexibility of rotation, and avoid The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

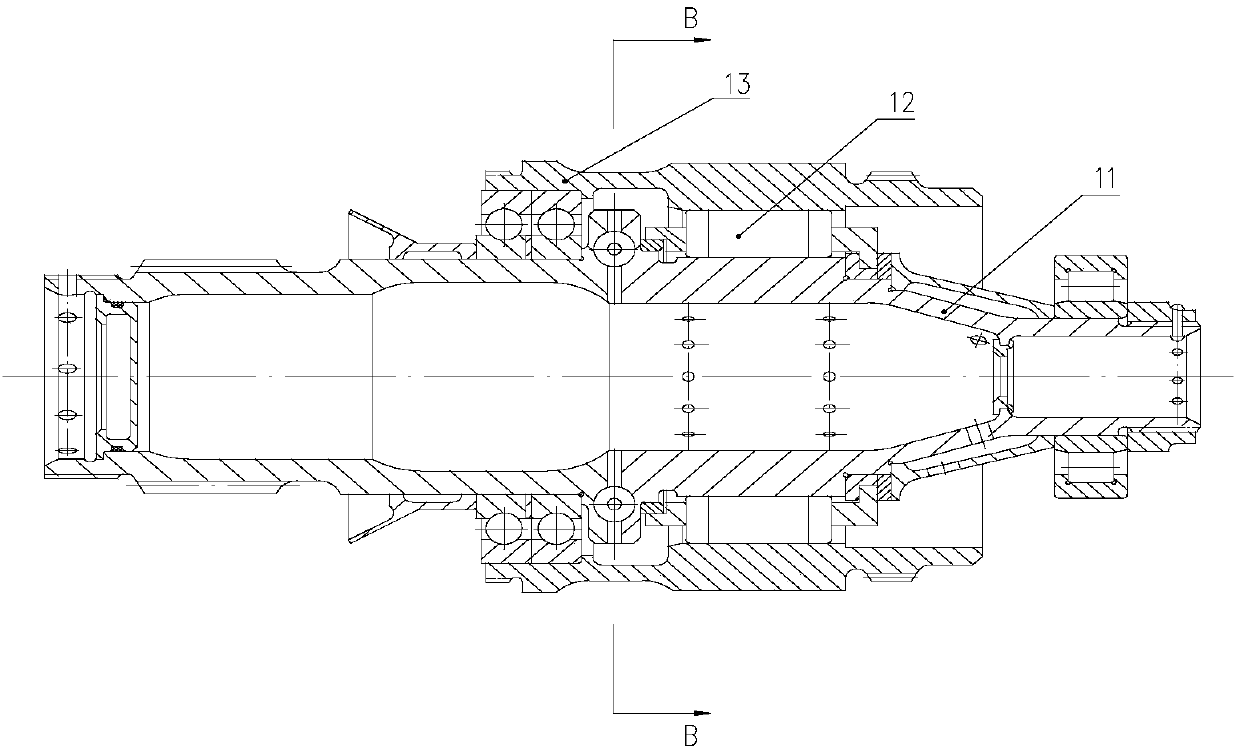

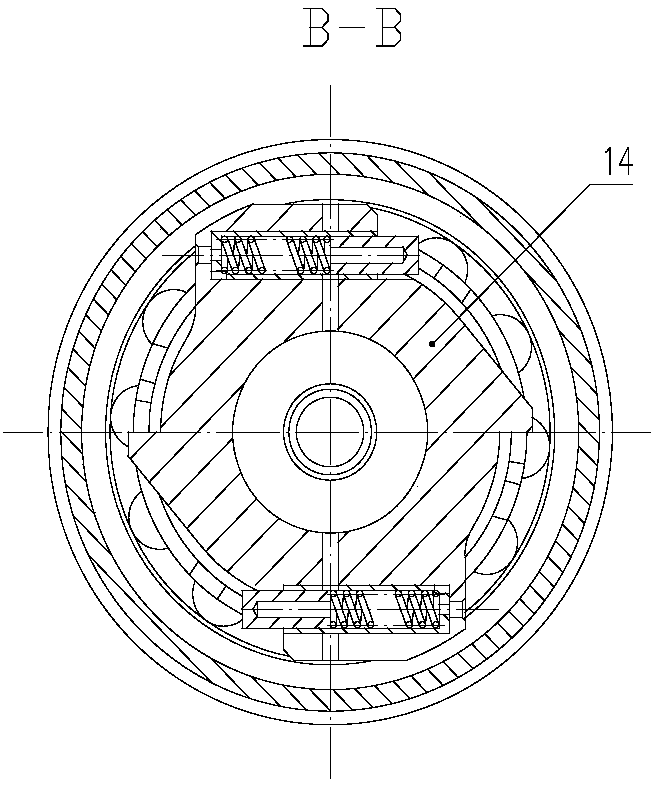

[0020] As shown in the figure, the assembly method of the roller overrunning clutch includes the following steps:

[0021] 1. Assemble the cage to the clutch shaft, and then install the assembly tool of the roller overrunning clutch from the small end of the clutch shaft;

[0022] 2. Install all the rollers in the semicircle of the assembly tool, and use the assembly tool as a guide to assemble the rollers, so that each roller can stay stably in the space formed by the semicircle, the cage and the groove of the clutch shaft;

[0023] 3. Install the outer ring;

[0024] 4. Withdraw the assembly tool from the small end of the clutch shaft to complete the assembly of the roller overrunning clutch.

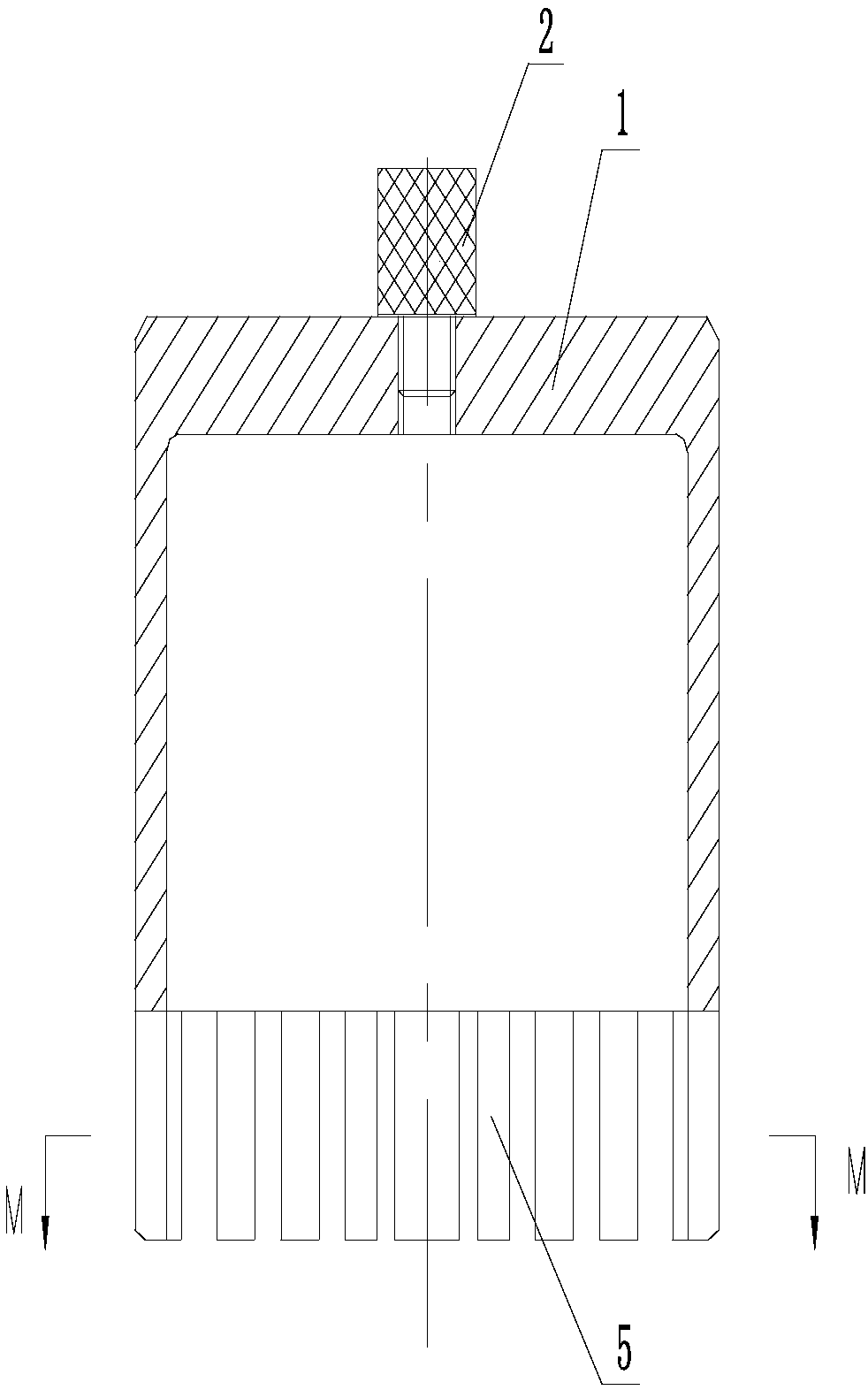

[0025] The assembly tool of the roller type overrunning clutch includes a fork 1 and a handle 2. The fork 1 is cylindrical in shape, and the bottom of the cylinder is provided with a threaded hole for assembling the handle 2. The cylindrical The depth of the shift fork 1 is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com