Injection mold

A technology of injection mold and injection cavity, which is applied in the field of injection mold, can solve the problems of reducing injection molding efficiency, producing quality defects, and the pressure of injection molding machine cannot be transmitted uniformly and quickly, so as to improve injection molding efficiency and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the embodiments and drawings, which are only for explanation and not intended to limit the protection scope of the present invention.

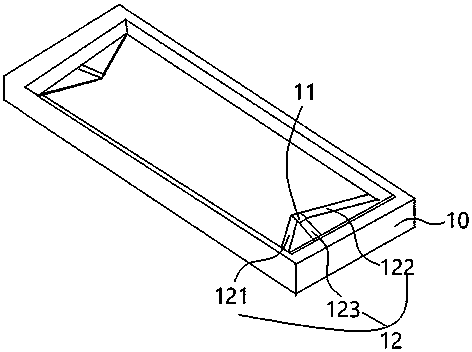

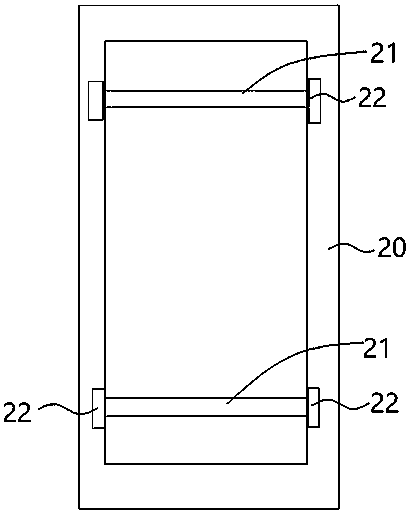

[0012] as attached figure 1 As shown in ~2, the injection mold described in this embodiment is composed of an upper mold 10 and a lower mold 20. The upper mold 10 is provided with a glue filling port 11, and the glue filling mouth 11 penetrates the entire upper mold from the opening on the upper surface of the upper mold. The glue port is connected with a plurality of diversion grooves 12 at the exit of the lower surface of the upper mold, and the diversion grooves 12 extend from the glue filling port on the inner surface of the upper mold to the cavity of the lower mold corresponding to the shape and size of the part to be injected.

[0013] In this embodiment, the cavity to be injected of the lower mold is a relatively long rectangular structure, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap