Windshield wiper reset device

A reset device, wiper technology, applied in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve problems such as affecting flight tasks and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

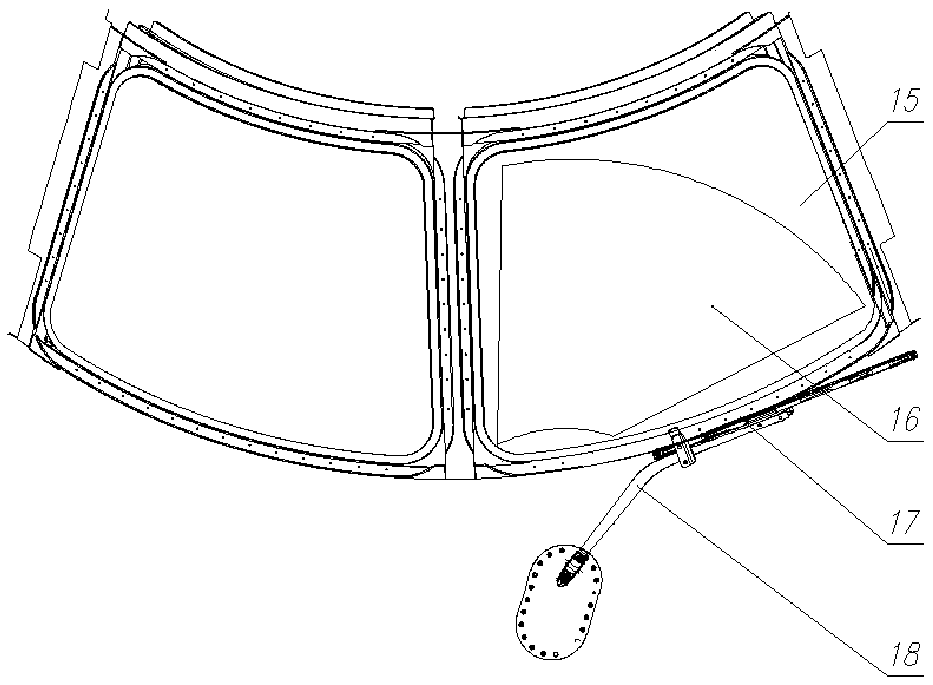

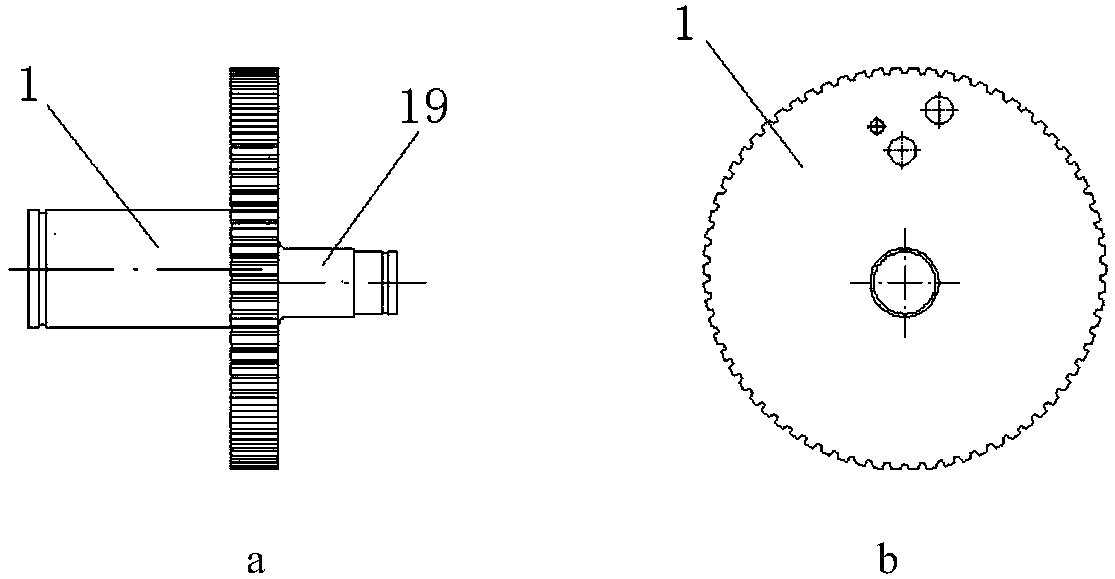

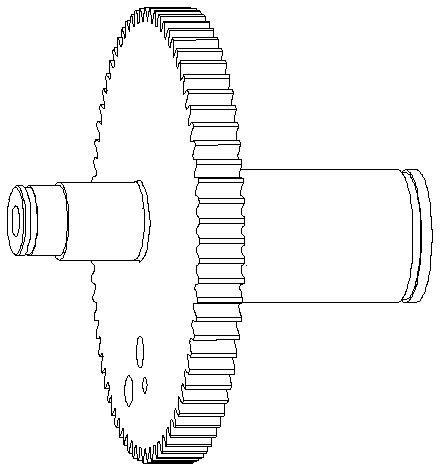

[0034]This embodiment is a wiper reset device, including a gear 1, a connecting rod 7, an eccentric bush 9, a coil spring 13, and a barrel 12; wherein, the eccentric bush 9 is set on the eccentric shaft 19 at one end of the gear, One end of the connecting rod 7 is sleeved on the eccentric bushing; the barrel 12 is sleeved on the eccentric bushing, and the inner end surface of the barrel is attached to the outer end surface of the connecting rod. One end of the coil spring 13 is hung on the lug on the end surface of the eccentric bushing, the other end is located on the end surface of the connecting rod, and is hung on the fourth small shaft 8 fixedly connected to the connecting rod. The clockwork cover plate 14 fits on the eccentric shaft and is used to limit the axial position of the coil spring. A third small shaft 6 is installed at the outer edge of the end face side of one end of the eccentric shaft 19 on the gear 1, and the block 3 is sleeved on the third small shaft. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com