Quilt sewing machine integrating folding and packaging

A quilt sewing machine and bed body technology, which is applied in the sewing machine, packaging, transportation and packaging of quilts, can solve the problems of reducing production efficiency and increasing transportation costs, so as to improve production efficiency, reduce transportation and space costs, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

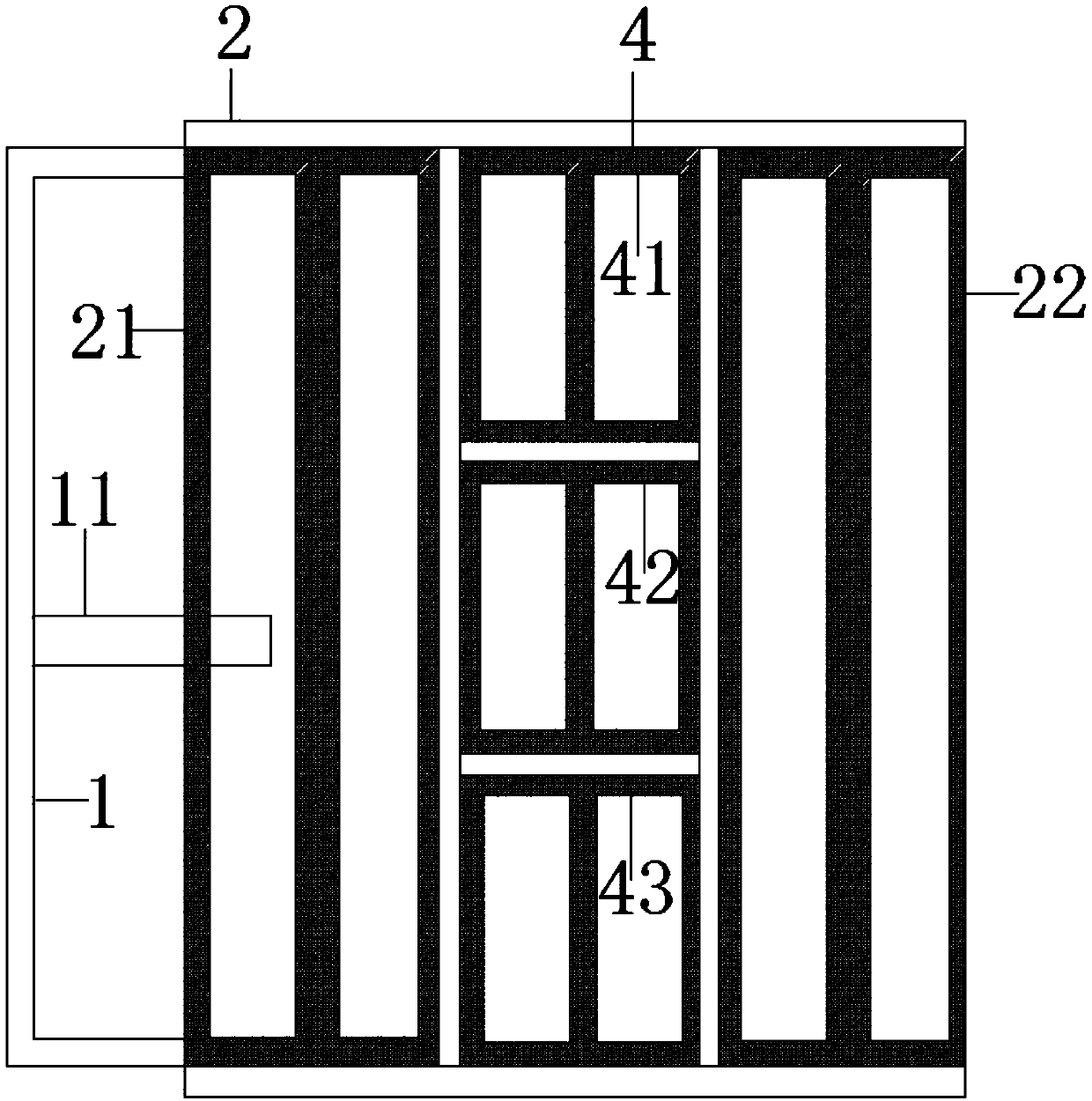

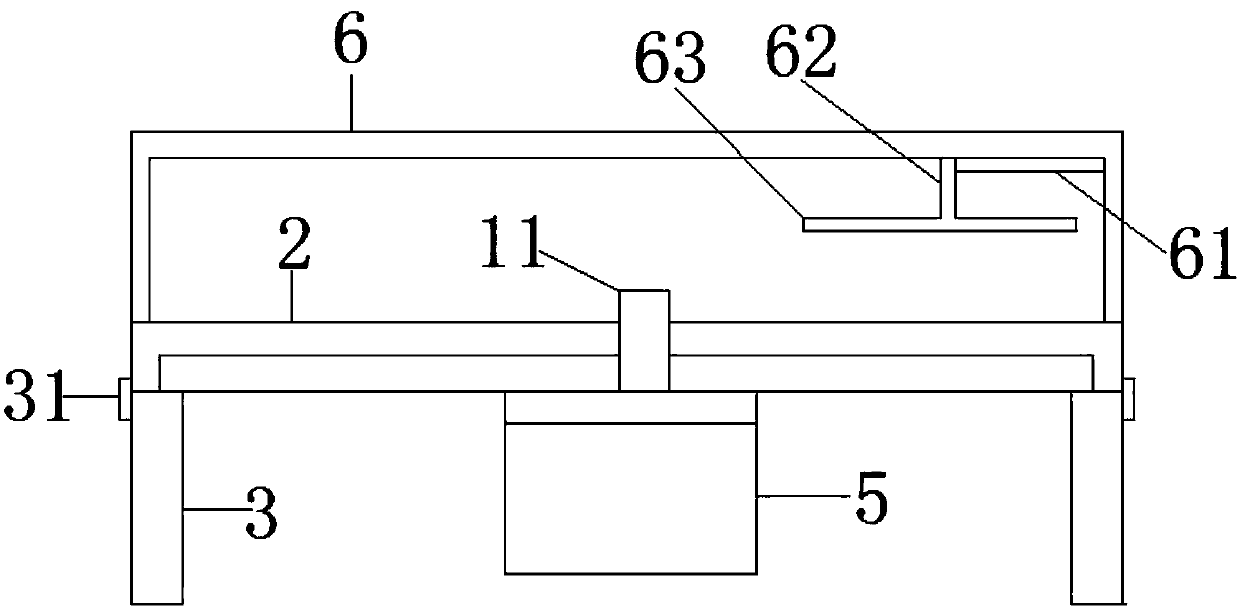

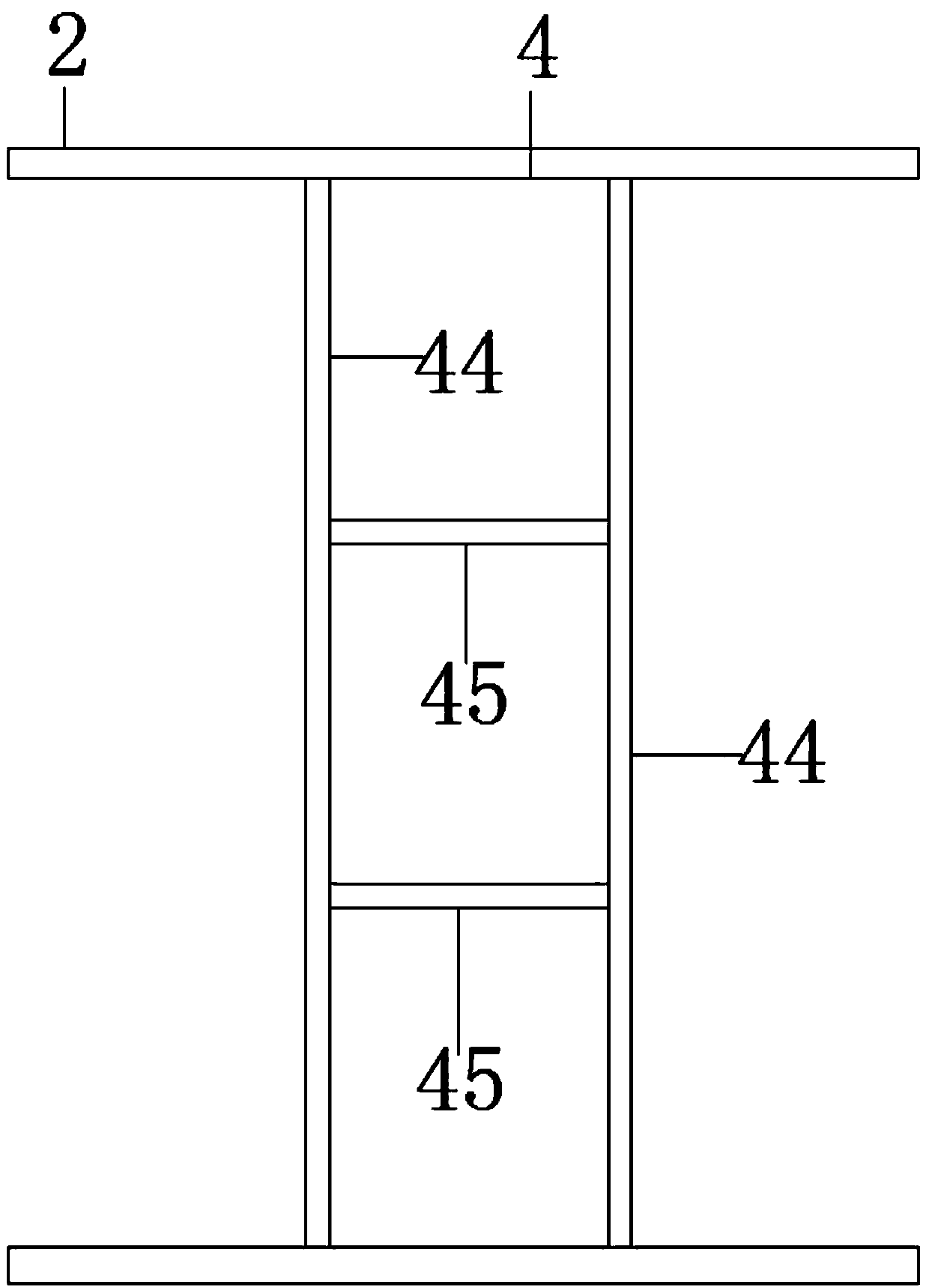

[0031] After the sewing is completed, pull the connecting piece 31 outwards to separate the second connecting block 33 from the connecting hole, rotate the second bed board 21, loosen the clamping piece of the second bed board 21, rotate the third bed board 22, and loosen the third bed board 22. The clamping part of the bed board 22, the electric telescopic rod works, the longitudinal telescopic rod 62 presses the quilt downward, the longitudinal telescopic rod 62 rises, the horizontal telescopic rod 61 pushes the longitudinal telescopic rod 62 forward, and the distance that the vertical telescopic rod 62 moves is equal to the pressing plate 63 length, the longitudinal telescopic rod 62 presses the quilt downwards again, the longitudinal telescopic rod 62 rises, the horizontal telescopic rod 61 pushes the longitudinal telescopic rod 62 forward again, and the longitudinal telescopic rod 62 presses the quilt downward again, and the longitudinal telescopic rod 62 Ascend, the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com