Liquid coating packing device capable of reducing loss quantity

A technology of liquid paint and loss, which is applied in the direction of unloading device, transportation and packaging, and the type of packaged items. It can solve the problems of easy drying of paint and drying of filling paint, and achieve long storage time, good sealing, and The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

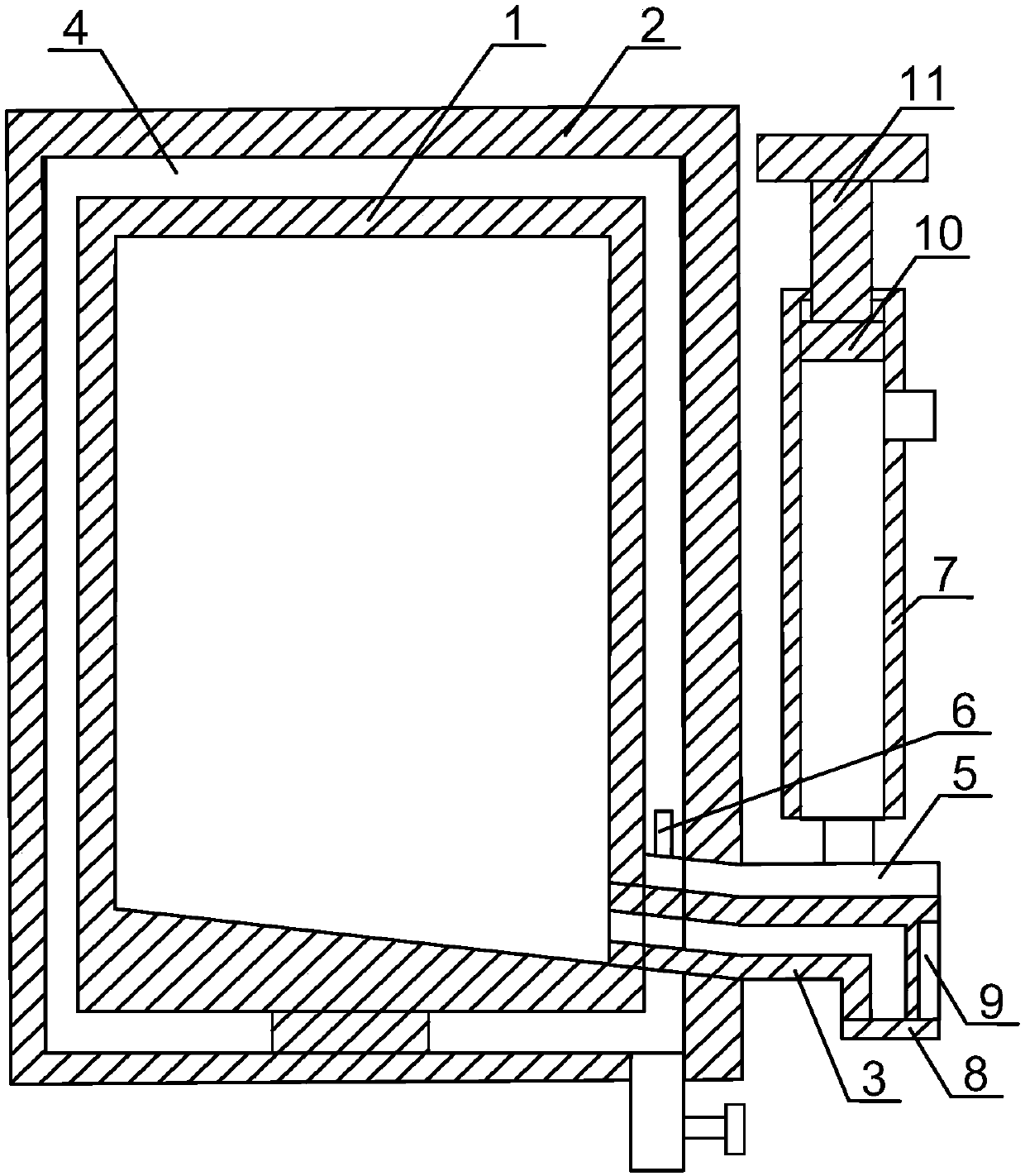

[0022] like figure 1 As shown, the liquid paint packaging device for reducing loss in the present invention includes a cylindrical tank body 1, and a suit tank 2 matching the shape of the tank body 1 is set on the outside of the tank body 1, and the gap between the suit tank 2 and the tank body 1 is A cavity 4 is provided, and a liquid outlet pipe 3 is communicated with one side of the tank body 1, and the liquid inlet of the liquid outlet pipe 3 is communicated with the bottom of the tank body 1, and the liquid outlet of the liquid outlet pipe 3 passes through the set tank 2 and Located on the outside of the set tank 2, the liquid outlet of the liquid outlet pipe 3 faces downward, the liquid outlet pipe 3 is provided with a cover plate 8 for blocking the liquid outlet, and the upper pipe wall of the liquid outlet pipe 3 is provided with a channel 5, so The channel 5 is connected to the outer wall of the tank body 1, and a nozzle 6 communicating with the channel 5 is arranged ...

Embodiment 2

[0025] Based on Embodiment 1, the cover plate 8 is connected with the wall of the liquid outlet of the liquid outlet pipe 3 with a magnet, and a groove 9 for placing the cover plate 8 is provided on the side wall of the liquid outlet pipe 3. A magnet piece connected to the cover plate 8 is arranged in the slot 9 .

[0026] The magnet connection is easy to operate, the connection is good, the cover plate will fall off automatically, the magnet connection has good sealing performance, the cover plate is easy to put on and take off, and the speed is fast; the groove is used to place the cover plate to prevent the cover plate from being polluted or damaged. lost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com