Pressure reducing valve

A pressure reducing valve and valve body technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve problems such as incomplete completion, multiple pressure reducing valve components, low output pressure, etc., to improve the pressure reducing accuracy and prolong the service life , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is further described.

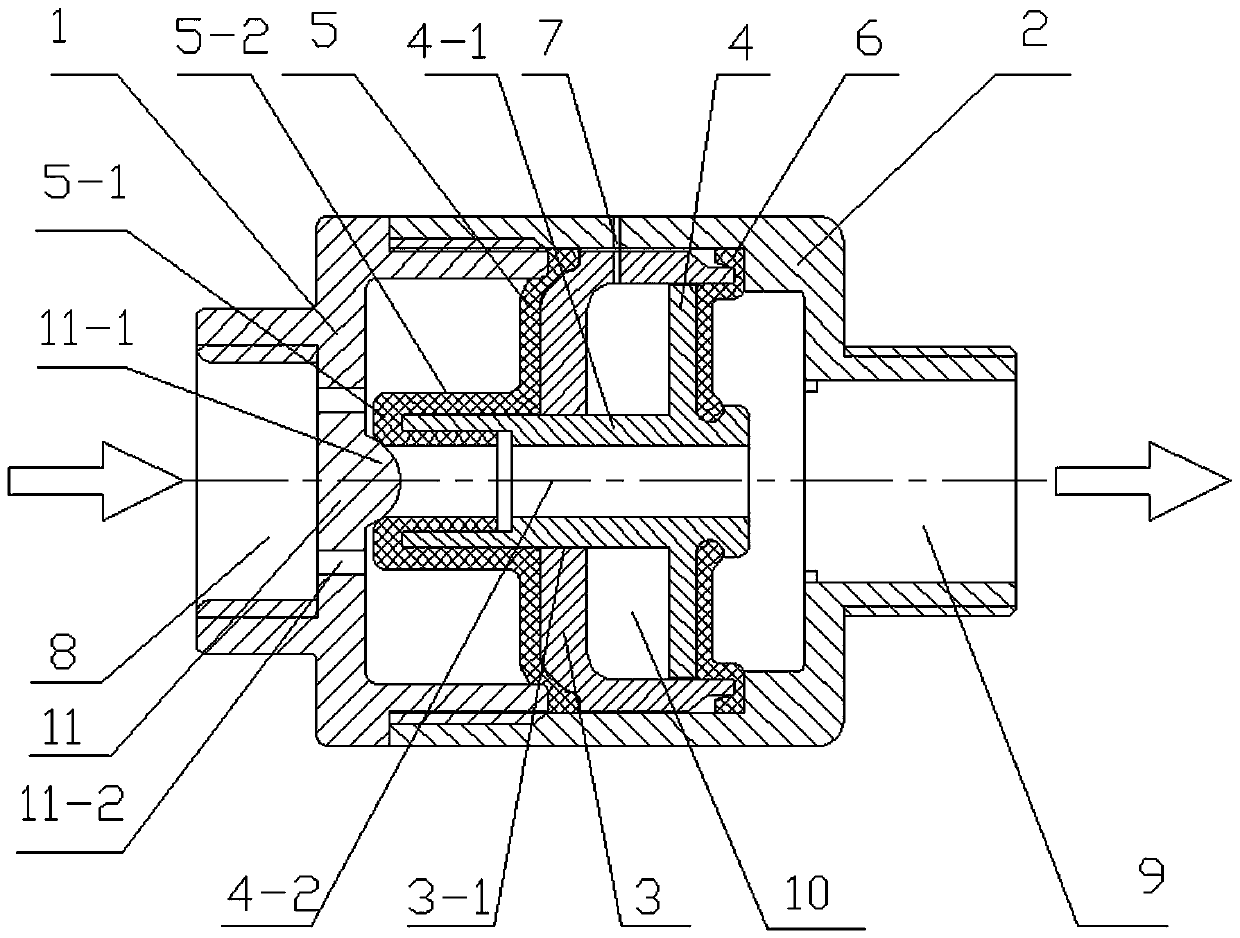

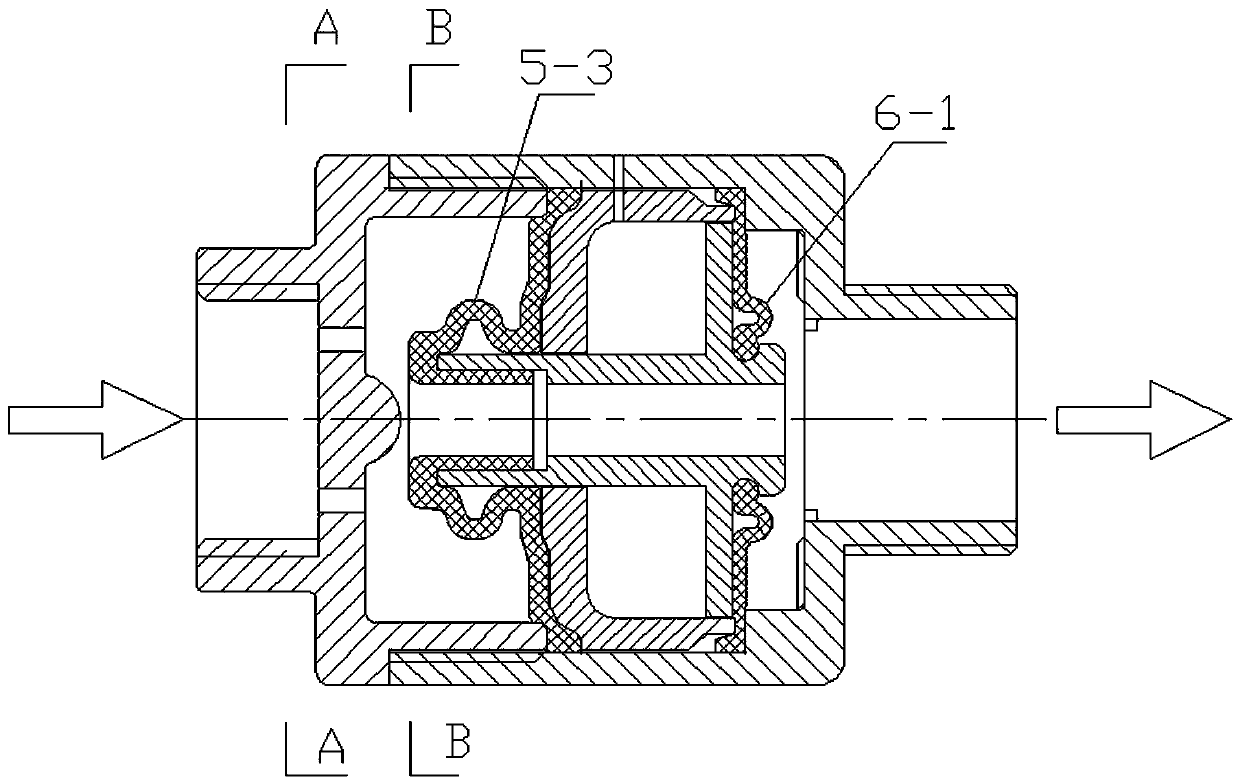

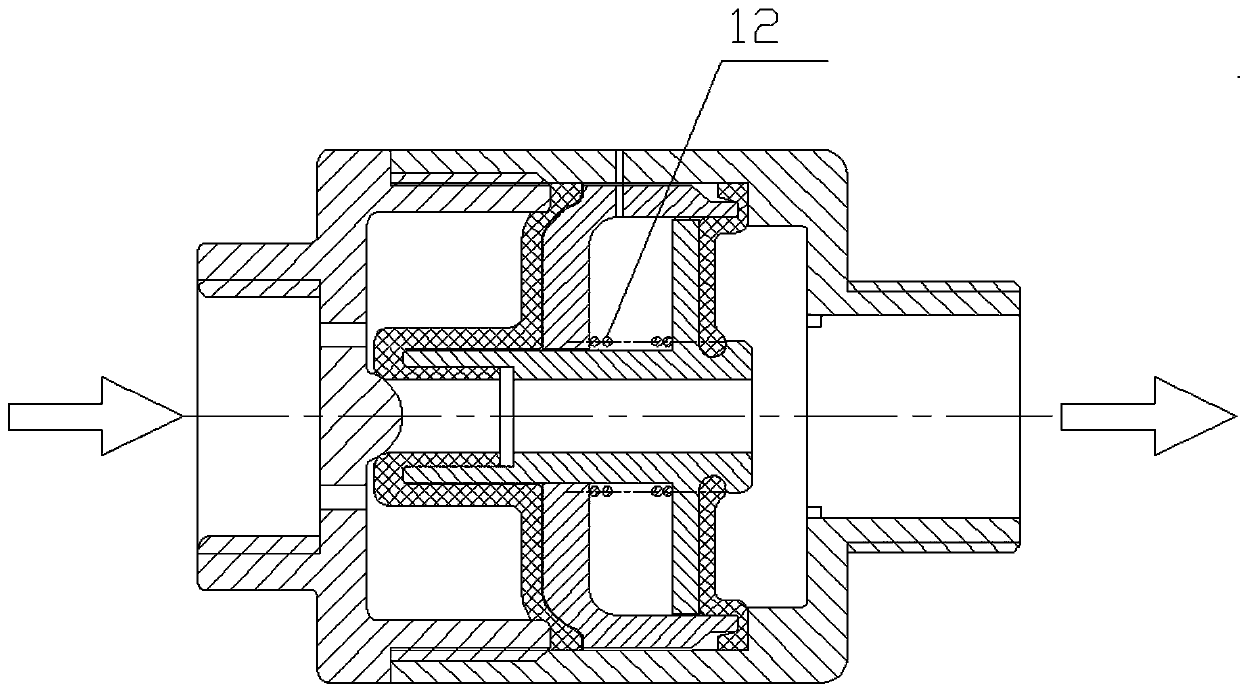

[0032] as attached Figure 1-Figure 5 A pressure reducing valve shown includes a valve body, one end of the valve body is a high-pressure chamber 8 connected to a high-pressure pipeline, and the other end of the valve body is a low-pressure chamber 9 connected to a downstream pipeline. The cavity is equipped with a support sleeve 3, which divides the inner cavity of the valve body into a high-pressure half area connected with the high-pressure chamber 8 and a low-pressure half area communicated with the low-pressure chamber 9, and the end of the support sleeve 3 facing the high-pressure chamber 8 is a closed end , the end of the support sleeve 3 facing the low-pressure chamber 9 is an open end;

[0033] The supporting sleeve 3 is equipped with a piston 4 that can slide axially in the inner cavity 10 of the supporting sleeve. The outer wall of the piston 4 is slidingly matched with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com