Double-shake table model test device capable of independently providing single DOF horizontal torsional vibration load

A model test device, a technology of torsional vibration, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of immature seismic effects and insufficient development of test devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

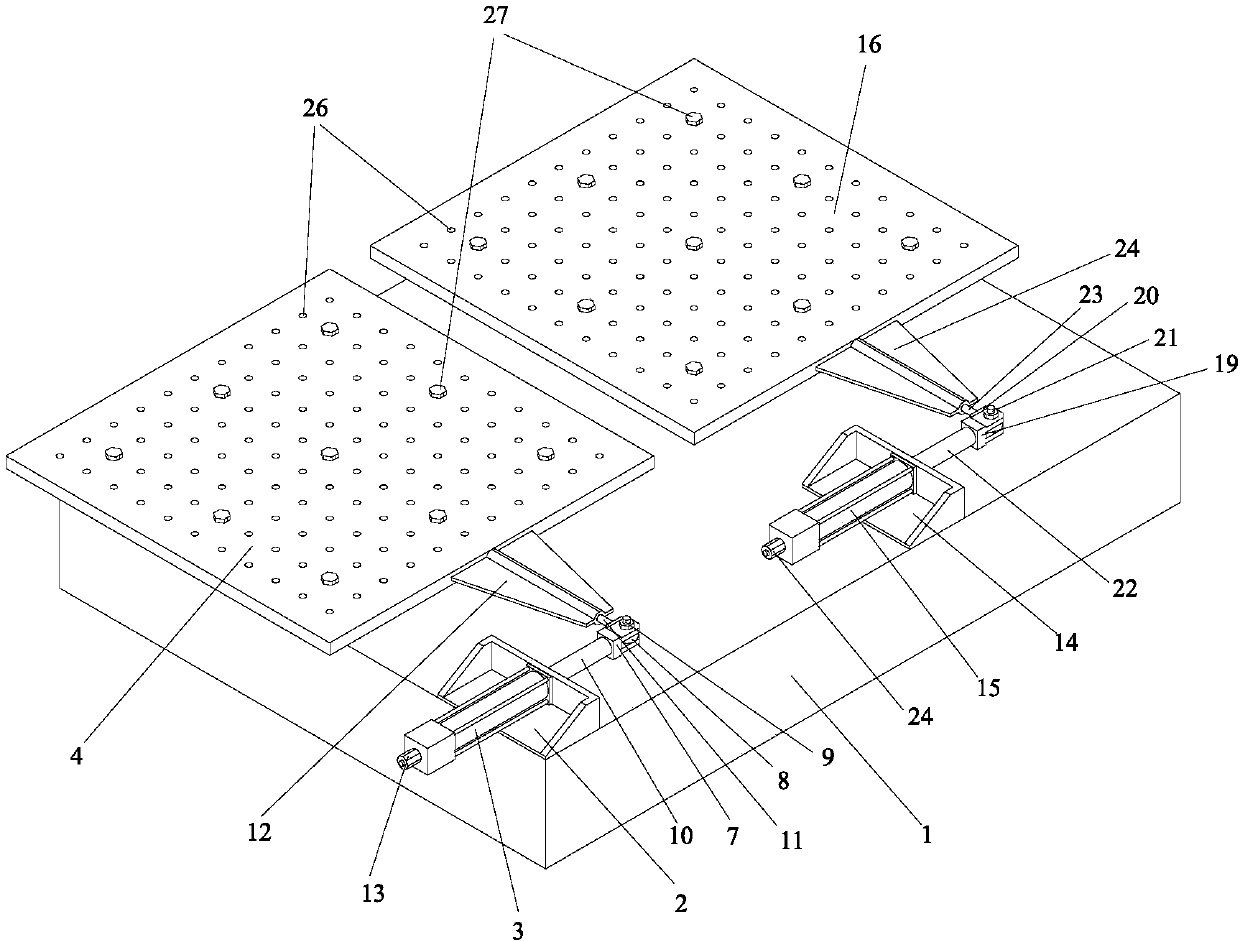

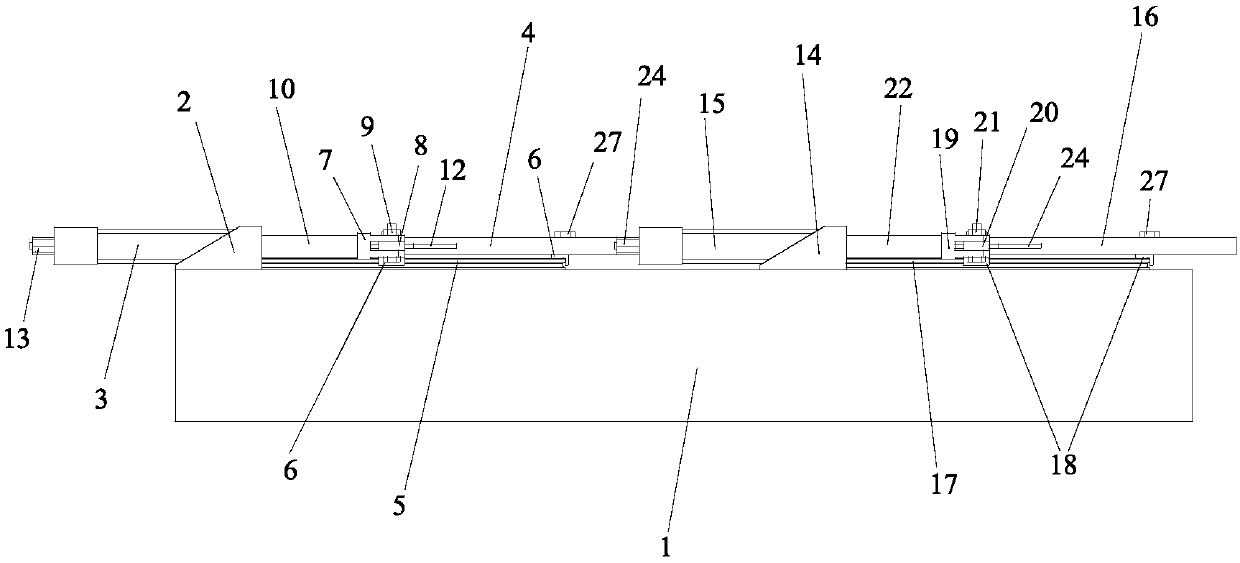

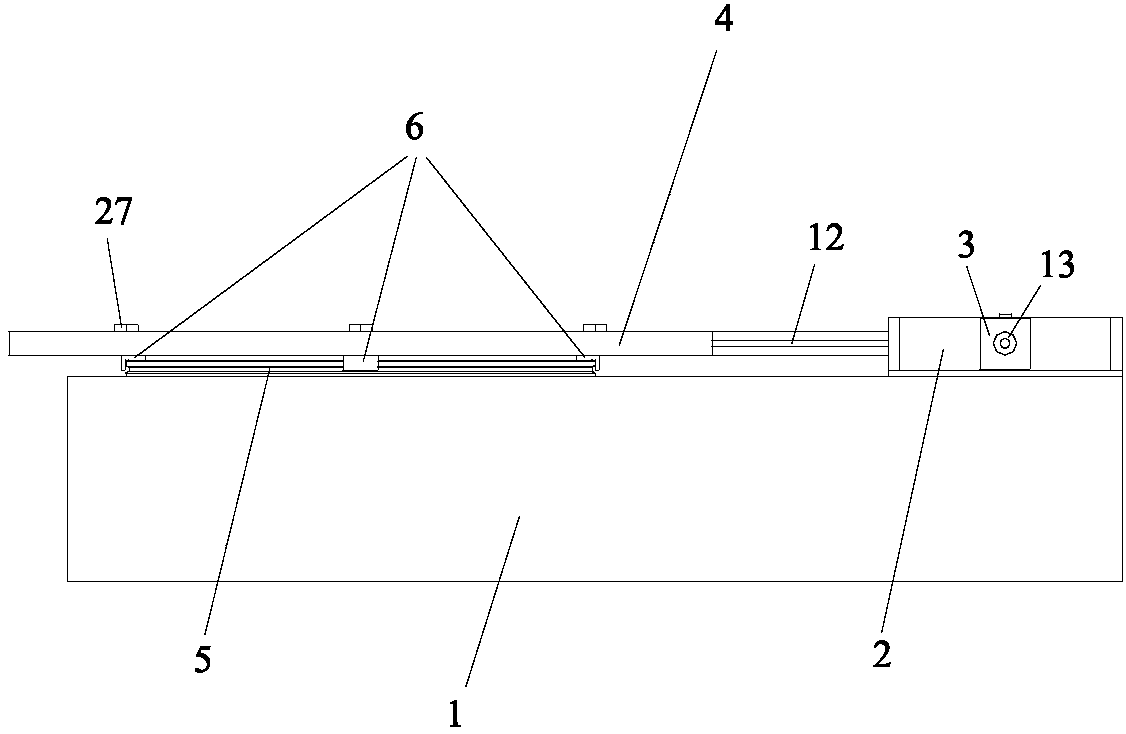

[0031] A shaking table model test device for providing earthquake overturning vibration load, consisting of a fixed system, a first actuator system, a first shaking table top system, a second actuator system, and a second shaking table top system, wherein:

[0032]The fixing system is composed of a base 1, a first actuator fixing bracket 2, a first vibration table slide rail 5, a second actuator fixing bracket 14, and a second vibration table slide rail 17. The first actuator fixing bracket 2. The first vibrating table slide rail 5, the second actuator fixing bracket 14, and the second vibrating table slide rail 17 are respectively welded on the base 1;

[0033] The first actuator system consists of the first actuator 3, the first actuator bayonet device 7, the first vibrating table bayonet device fixing bolt 9, the first vibrating table actuator telescopic rod 10, the first vibrating table The actuator acceleration sensor 13 is composed of the first actuator system. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com