A kind of abalone snail shelling device, processing system and processing technology thereof

A processing technology and snail shell technology, which is applied in the field of abalone snail shelling device, can reduce the probability of secondary pollution, improve efficiency and yield, and be easy for human body to digest.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] After the fresh flower abalone is cleaned, it is shelled by the dehulling device, and then placed in a freezer for quick freezing for standby use; after the quick-frozen flower abalone is thawed and quickly frozen for the second time, it is sent to the slicer 3, the blanching device 4 and the rolling device. The kneading machine 5 automatically performs the three-step partially automatic process of low-temperature slicing, blanching and rolling and seasoning, and then separately controls the use of low-temperature slicing, blanching or rolling and seasoning according to the needs for further in-depth processing.

Embodiment 2

[0078] After the fresh flower abalone is cleaned, it is placed in a freezer for quick-freezing for later use; after the quick-frozen flower abalone is thawed and the second quick-frozen, a specific weight of seasoning is placed in the tumbler 5; after the second quick-freezing The finished flower abalone is sent to the flower abalone processing system for fully automatic processes of shelling, slicing, blanching and rolling and seasoning.

[0079] A kind of processing technology of flower abalone, adopts the described flower abalone shelling device, and carries out successively according to the following steps:

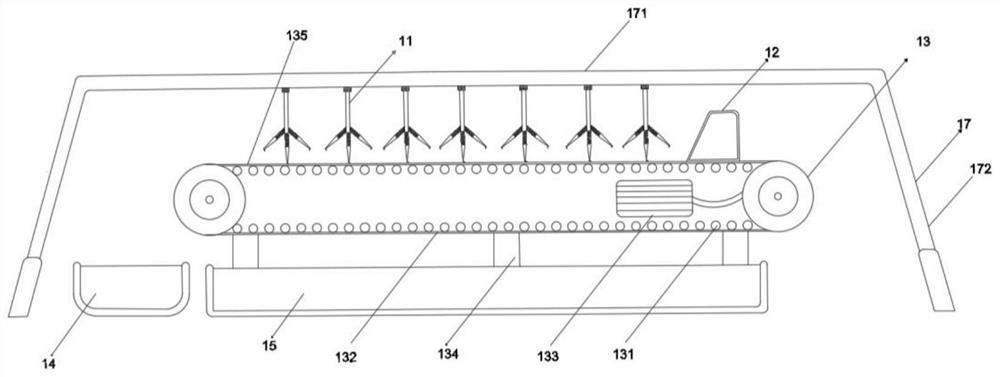

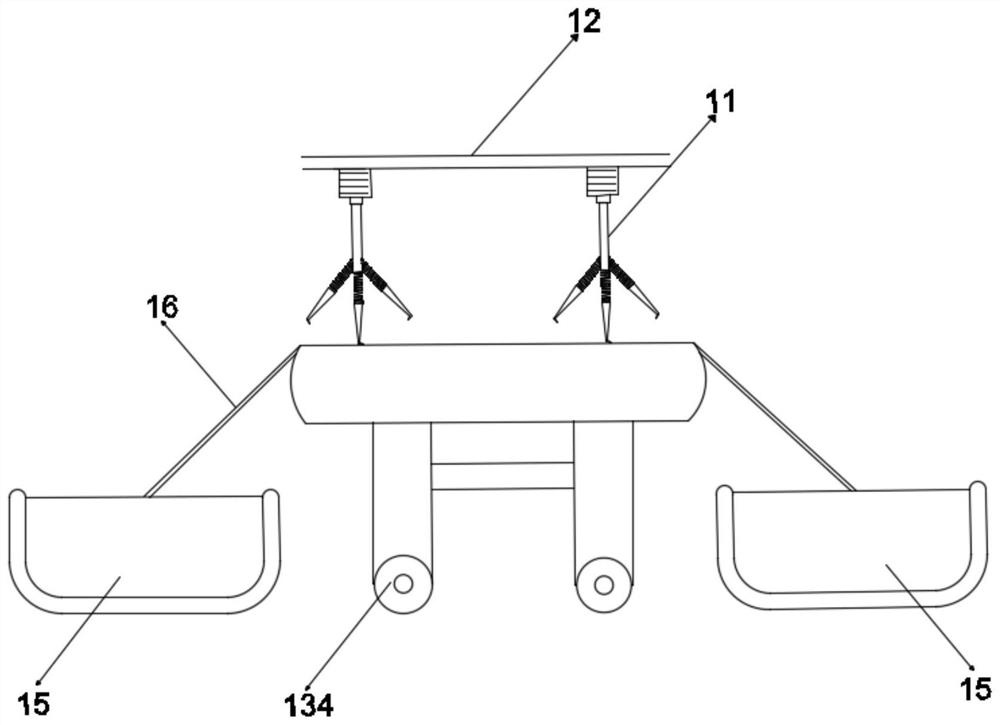

[0080] Step 1: After cleaning the fresh abalone snails, place the flower abalone snails in the feeding slide basin 12 and slide to the conveyor belt 132. Driven by the second stepping motor 133, the conveyor belt 132 continuously vibrates to adjust the position, and The flower abalone is fixed in the matching groove 135,

[0081] Under the action of the first step mo...

Embodiment 3

[0139] A kind of snail processing technology using snail processing system is carried out successively according to the following steps:

[0140] Step 1: After cleaning the fresh snails, start the shelling device 1, place the snails in the feeding slide basin 12 of the shelling device 1, slide to the conveyor belt 132, and the conveyor belt 132 is on the second stepping motor Driven by 133, the position is constantly adjusted by vibration, and the flower abalone is fixed in the matching groove 135,

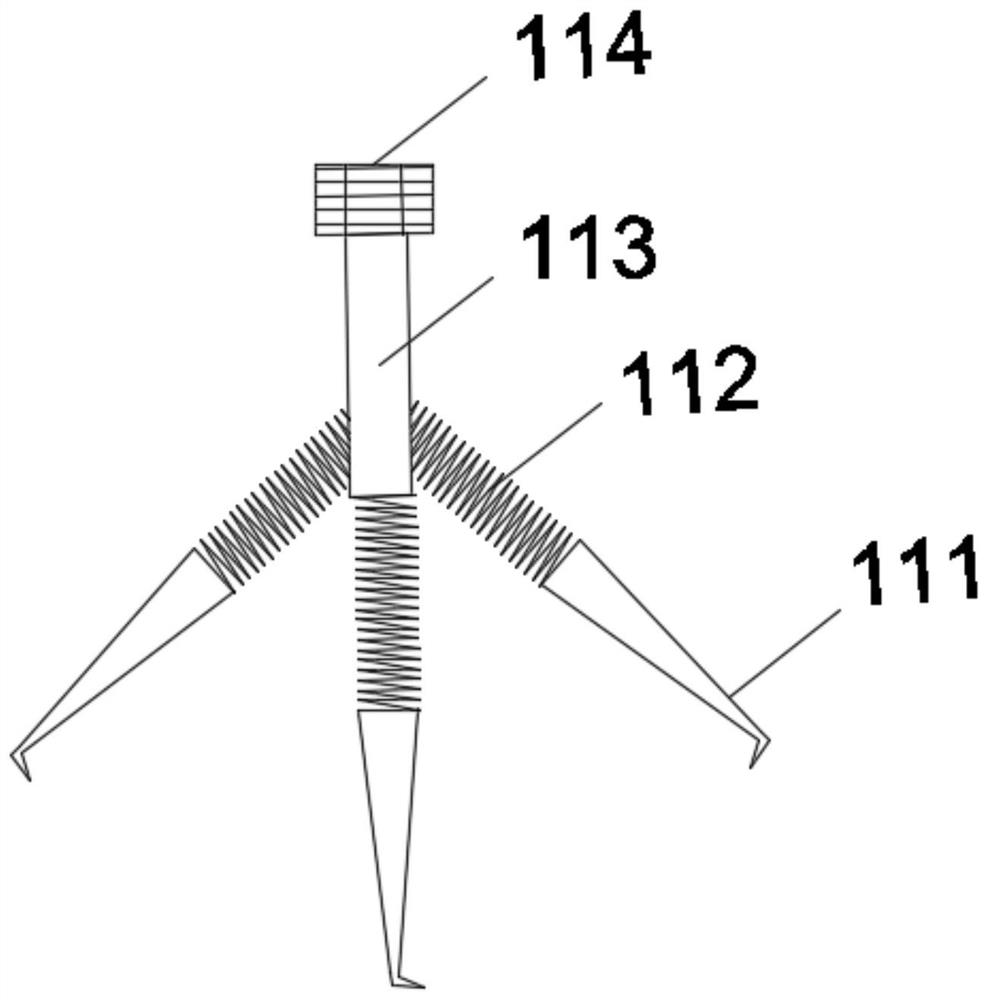

[0141] Under the action of the first stepping motor 114, the cutter 111 cuts the junction of the snail meat and the snail shell from the side, and the tip of the knife catches the snail meat and rotates it out of the snail shell, realizing The snail meat is separated from the snail shell, rotated to the highest point, and the snail meat is thrown into the discharge box 15, and the snail shell is transferred to the shell receiving box 14 to realize shell removal;

[0142] Step 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com