Machining device for automotive trim foam molding

A foam molding and processing device technology, applied in the field of automobile manufacturing, can solve problems affecting production efficiency, waste of manpower time, difficulty in picking up parts, etc., and achieve the effects of saving finished products, improving processing efficiency, and stable and firm connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

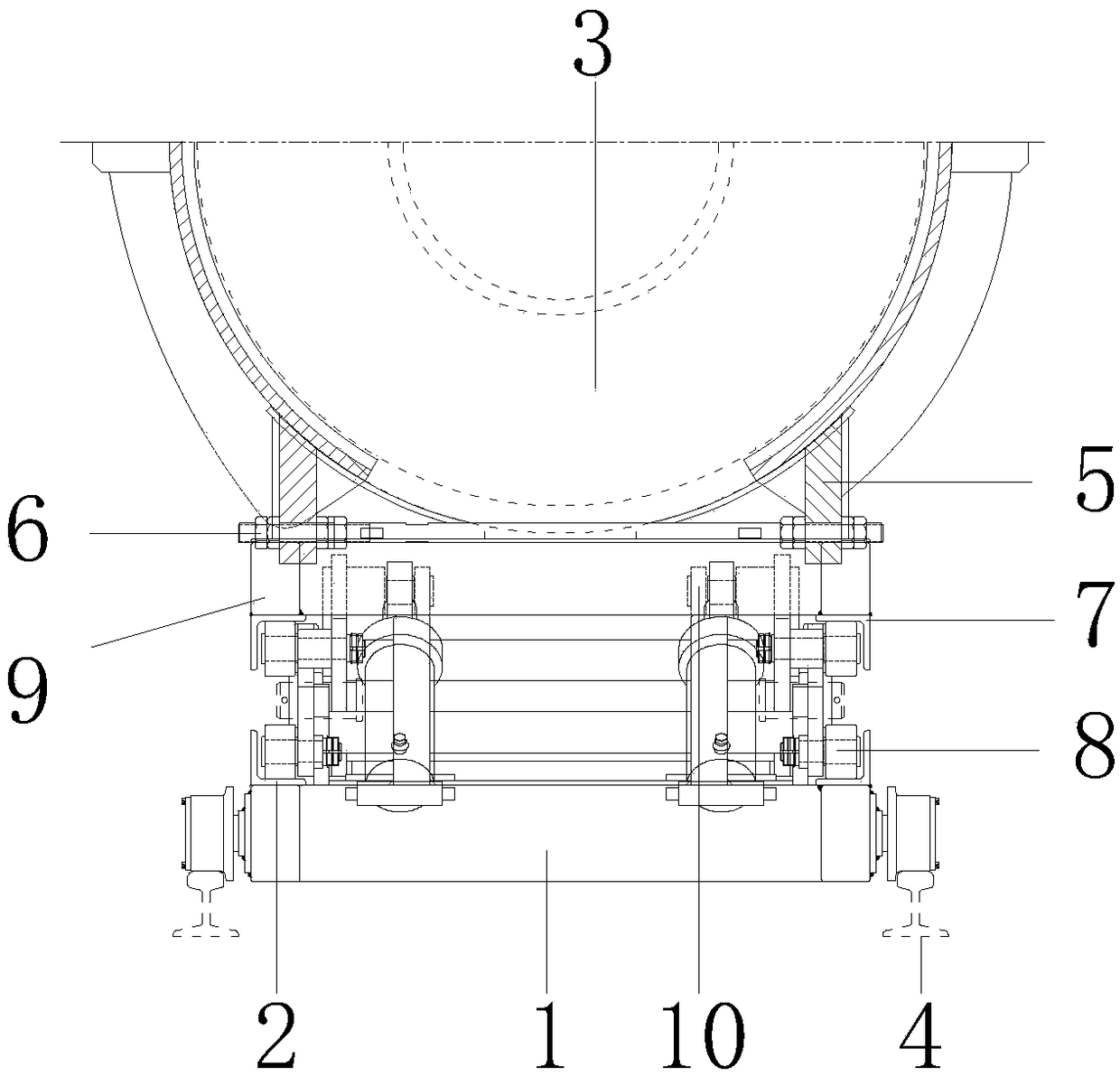

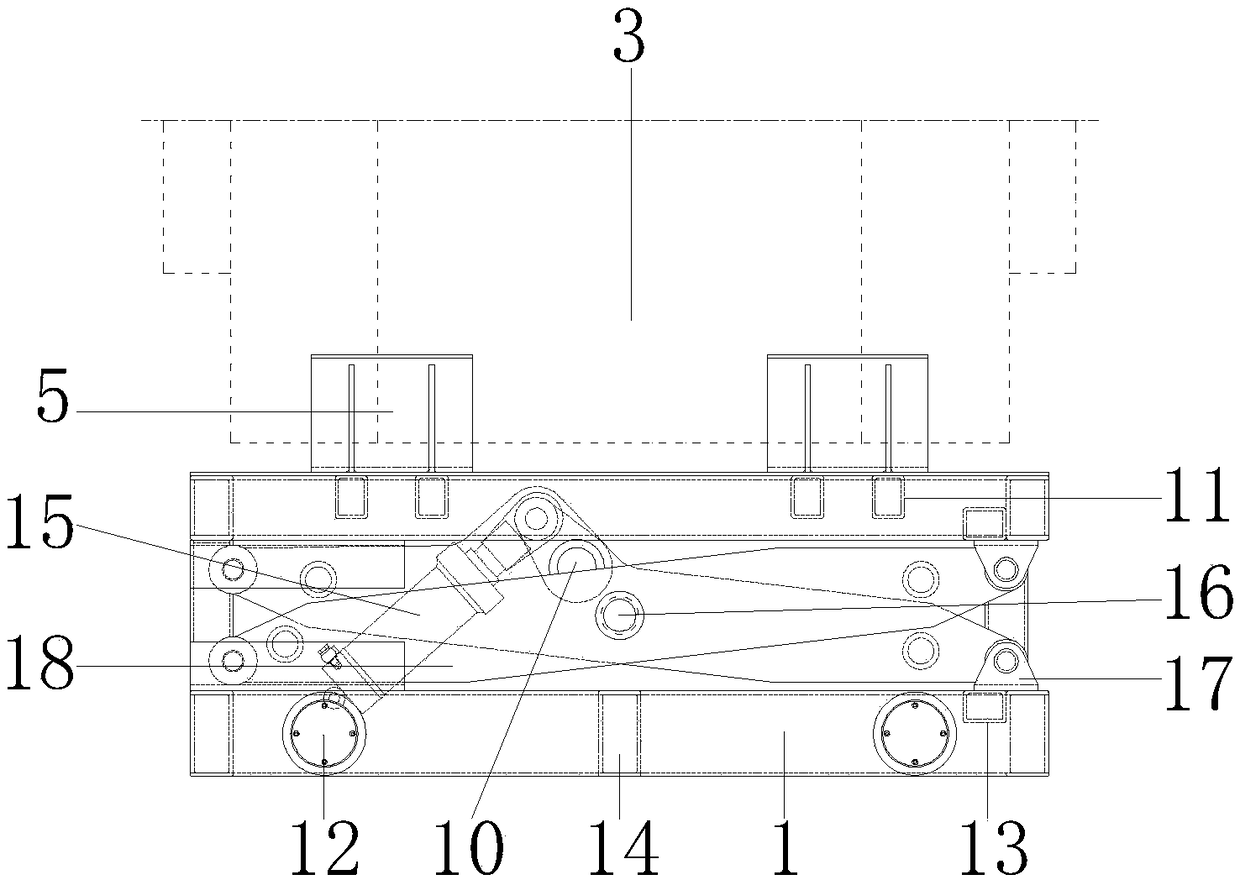

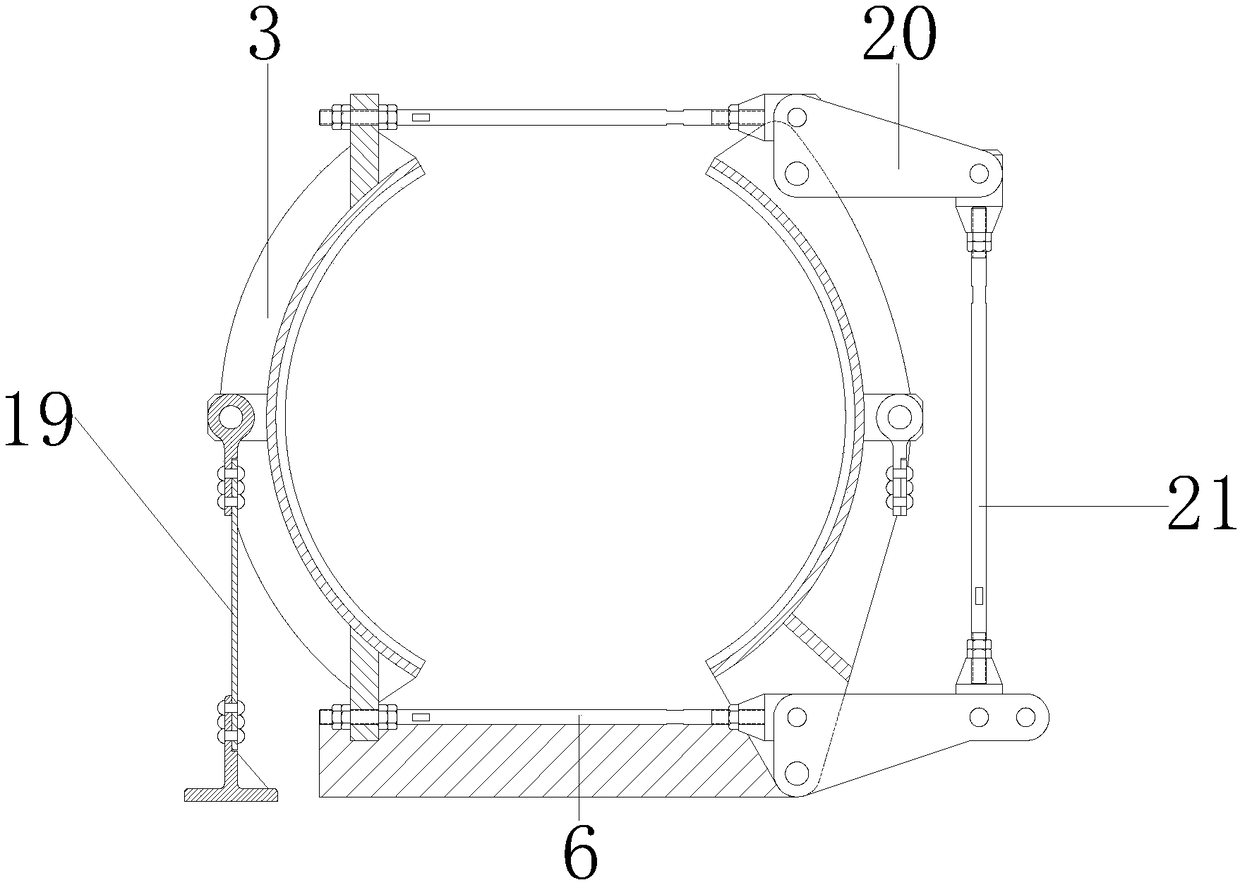

[0016] see Figure 1-4, the present invention provides a technical solution: a foam molding processing device for automobile interior decoration, including a base 1, the base 1 is made of stainless steel, and is used to install various internal parts, and the upper surface of the base 1 is equipped with a connecting corner code 2 , the connecting corner code 2 is made of stainless steel, which is used to connect and fix the triangular plate 17, the inner wall of the connecting corner code 2 is connected with the outer wall of the base 1, and a bottom cover 23 is installed on the right side outer wall of the base 1, and the bottom cover 23 is made of stainless steel, and is used for Gasket 25 is installed, the left side outer wall of bottom cover 23 is connected with the right side outer wall of base 1, and gasket 25...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap