Floating Alignment Vehicle Battery Automatic Swap Station

A battery, floating technology, used in charging stations, electric vehicles, vehicle maintenance, etc., can solve the problems of fixed influence on normal transmission of electricity, inability to ensure tightness, precision errors, etc., to avoid fitting failure, compact setting structure, The effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

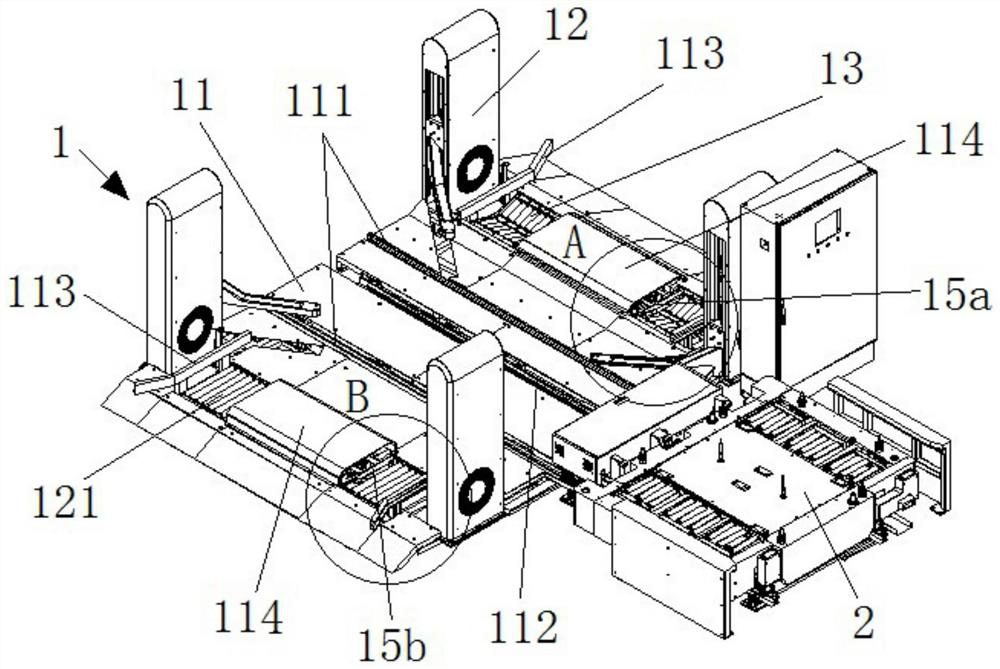

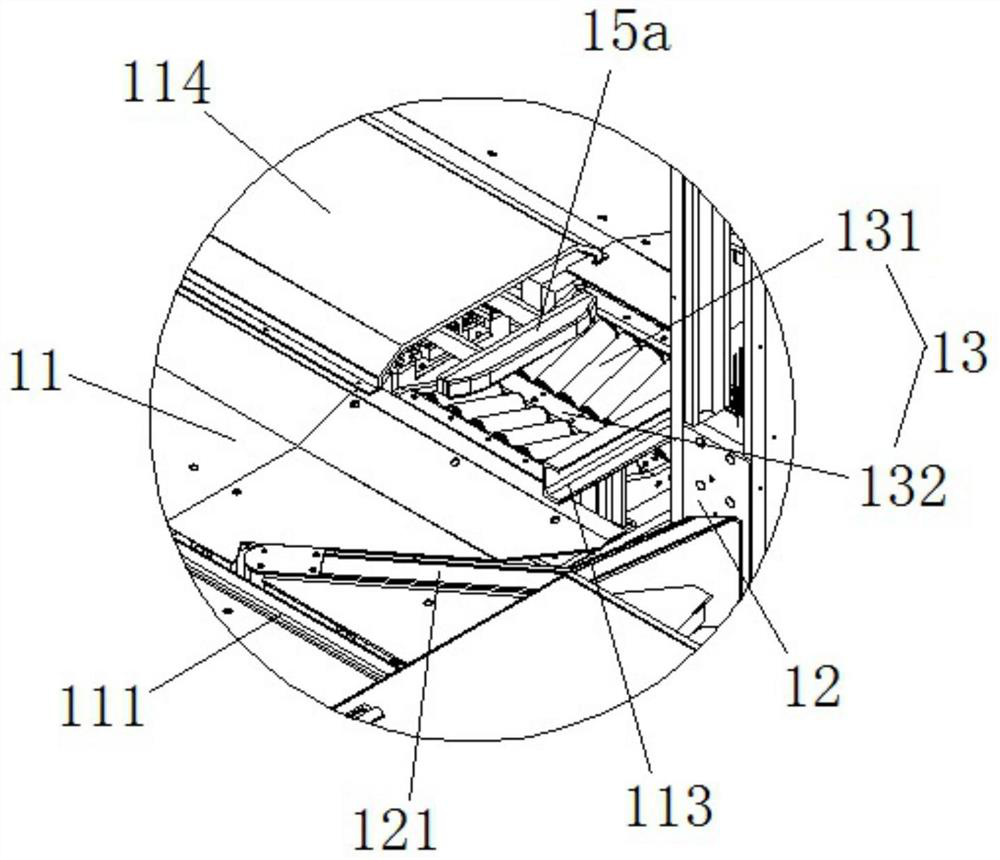

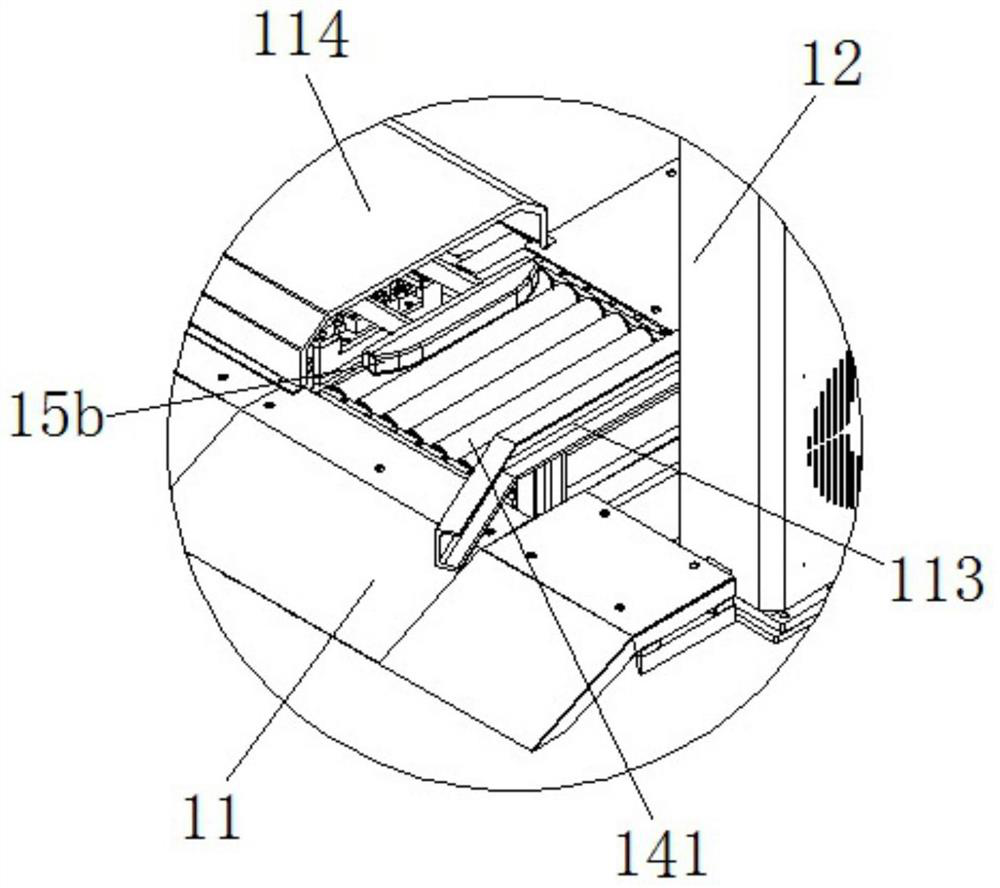

[0074] Such as Figure 1 to Figure 9As shown, a vehicle-mounted battery automatic replacement station of the present invention includes a car positioning lifting mechanism 1 and a battery unlocking mechanism 2; Four lifting assemblies 12, two front wheel alignment assemblies 13 located at the front of the support platform 11, two rear wheel alignment assemblies 14 located at the rear of the support platform 11, and two vehicle body alignment assemblies located in the middle of the support platform 11 15a, 15b, a vehicle body positioning assembly 15a is located between the two front wheel positioning assemblies 13, and another vehicle body positioning assembly 15b is located between the two front wheel positioning assemblies 14; the supporting platform 11 is provided with a Two parallel slide rails 111, the battery unlocking mechanism 2 moves along the slide rails 111; the battery unlocking mechanism 2 includes a jacking assembly 21, a positioning assembly 23 located on the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com