Steam air-guide condensation structure for steaming box

A technology of steam and condensed water, which is applied in the field of steam guiding and condensing structure, which can solve the problems affecting the use of the steam box, achieve the effect of increasing the effective contact area and promoting the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

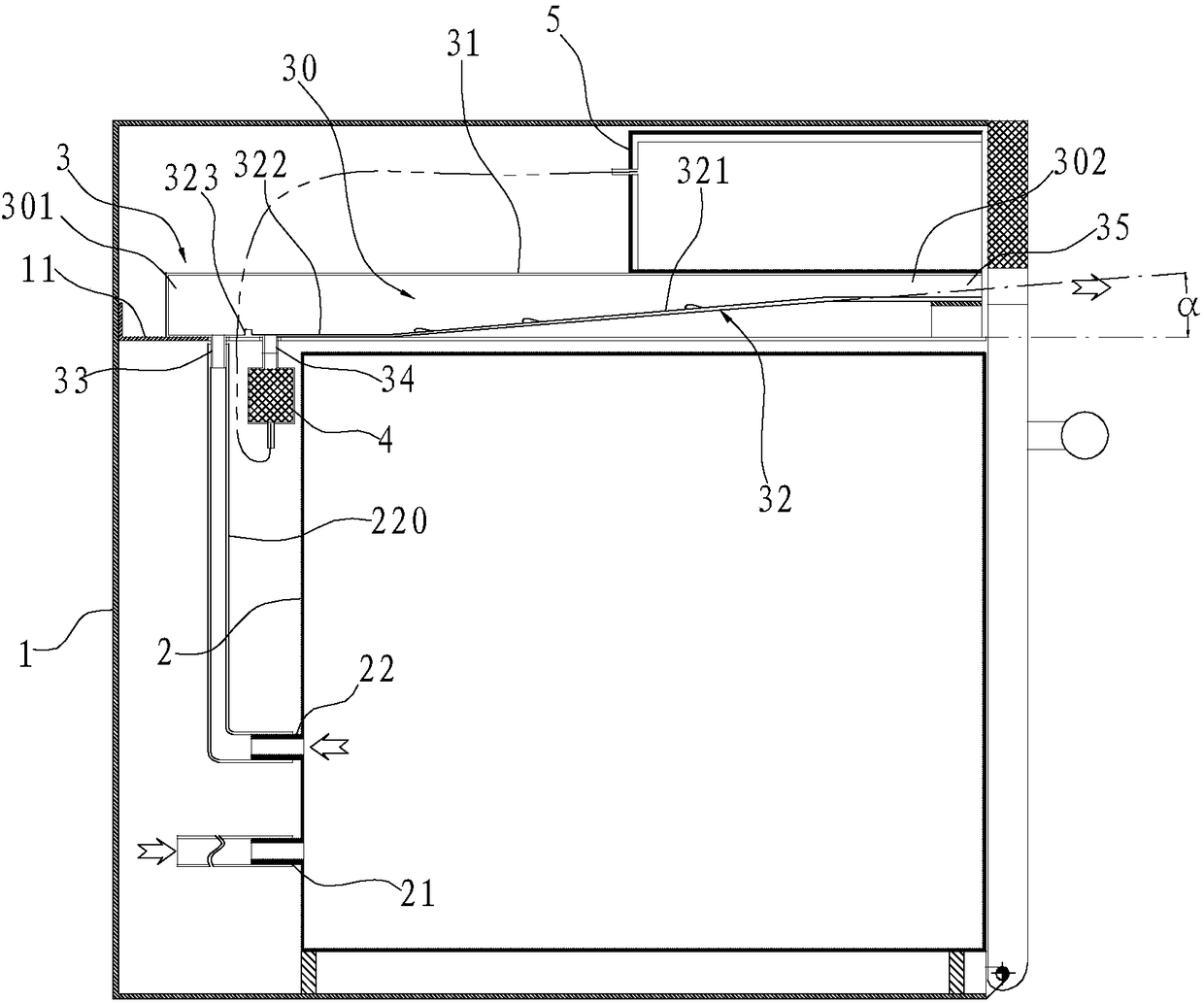

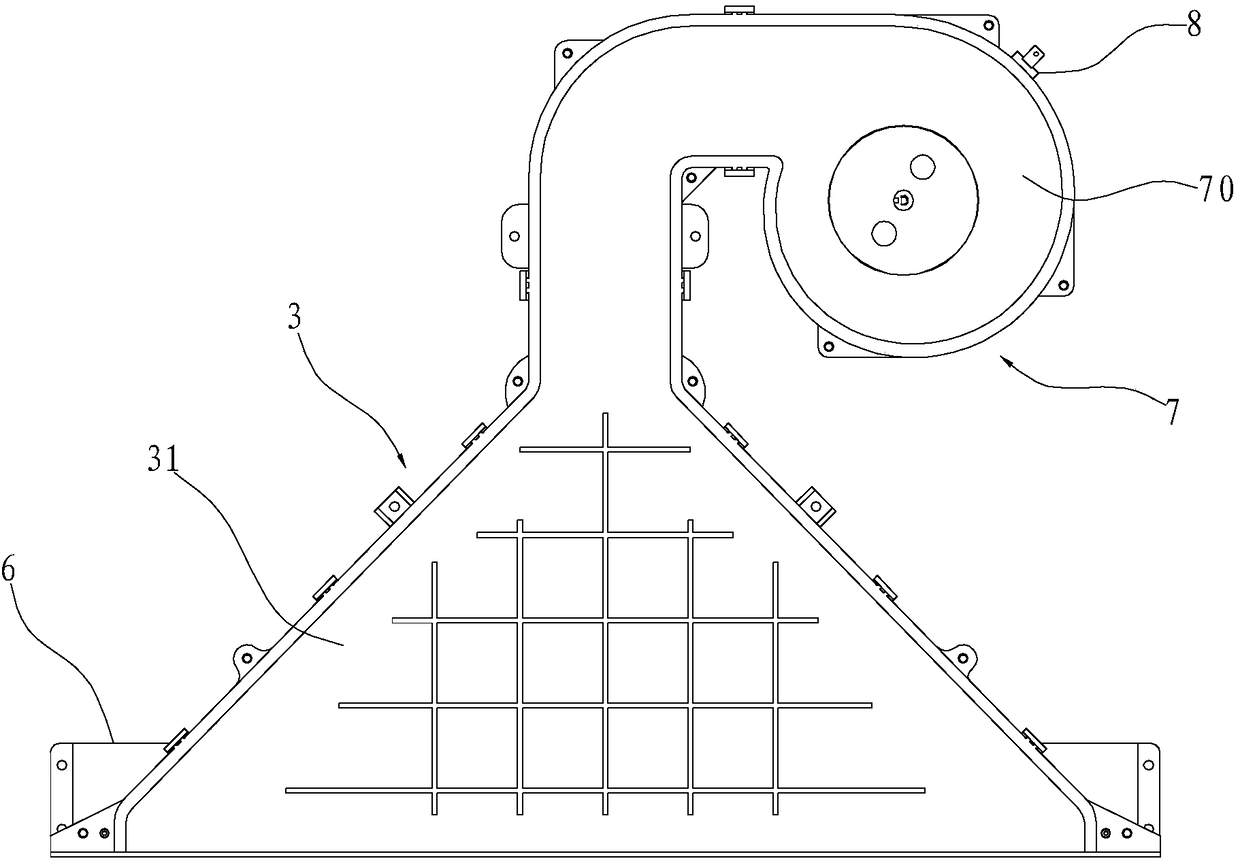

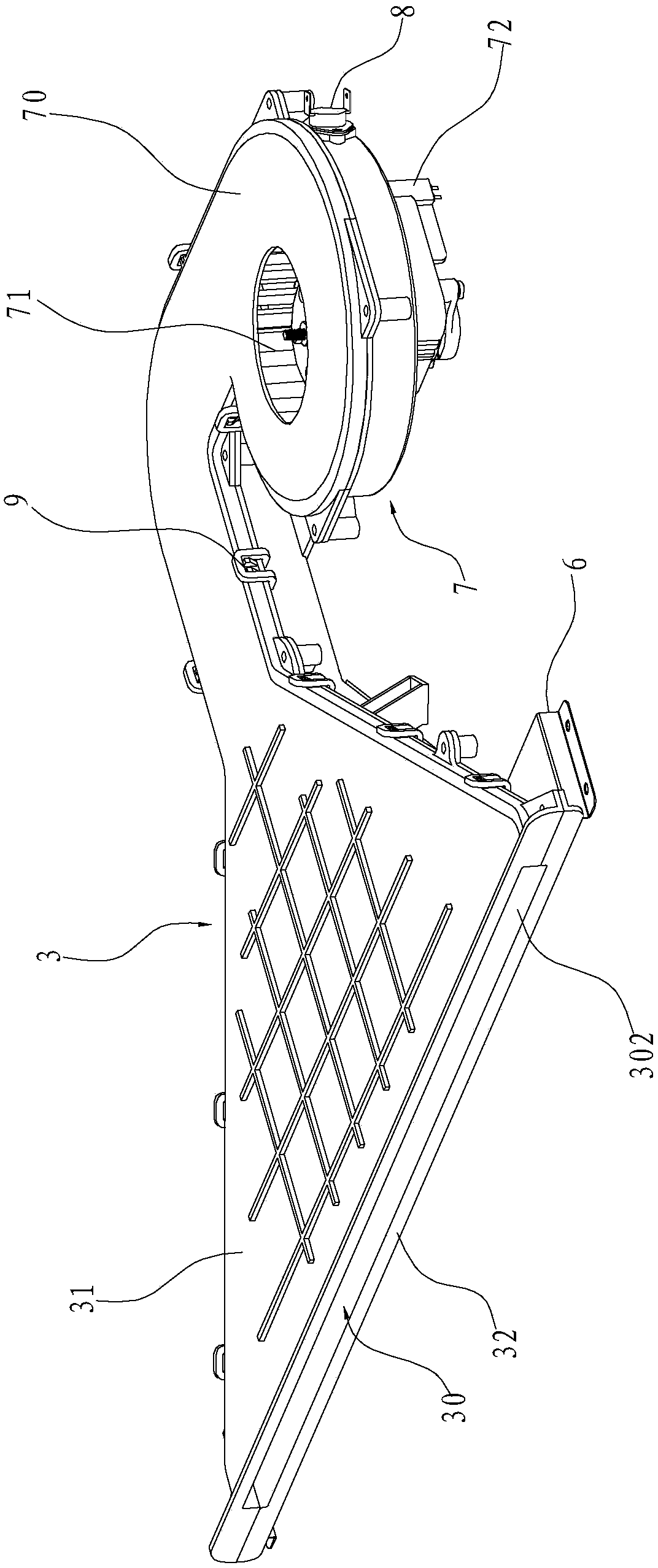

[0021] Such as Figure 1~4 As shown, a steam guiding and condensing structure for a steam box includes an air guiding plate 3, a fan 7 and a condensed water collecting device 4, wherein the air guiding plate 3 includes an upper cover 31 and a lower cover 32 that are buckled up and down, The upper cover 31 and the lower cover 32 surround and form an air guide channel 30, and one end of the air guide channel 30 is a steam inlet end 301, and the other end is an exhaust end 302, and the steam inlet end 301 is provided with a first air inlet port. The exhaust port 33 is provided with an exhaust port 35 on the exhaust end 302 . In this embodiment, the specific installation structure of the above-mentioned steam guide condensing structure in the steam box is as follows: the steam box includes a casing 1, and the inner cavity of the casing 1 is divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com