Working mirror with induction probe

A technology for sensing probes and working mirrors, applied in the field of working mirrors, can solve problems such as the application of MEMS probes, and achieve the effects of improving accuracy and high recognition, convenient operation, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

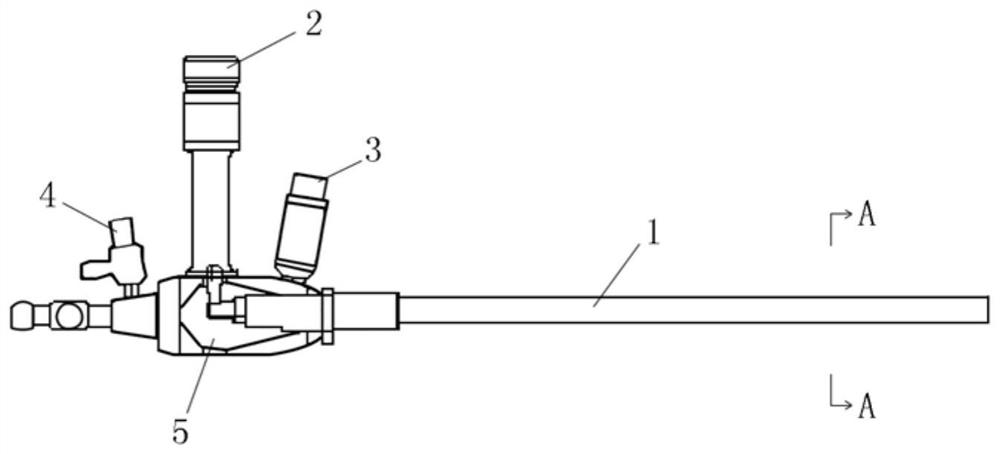

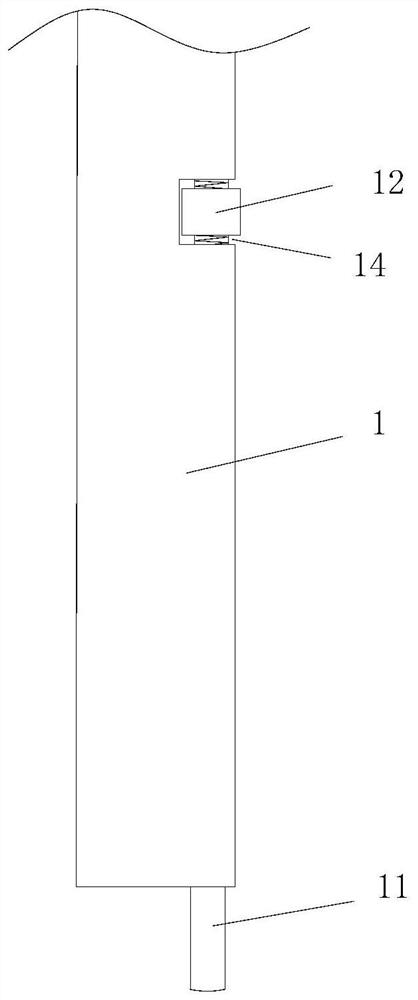

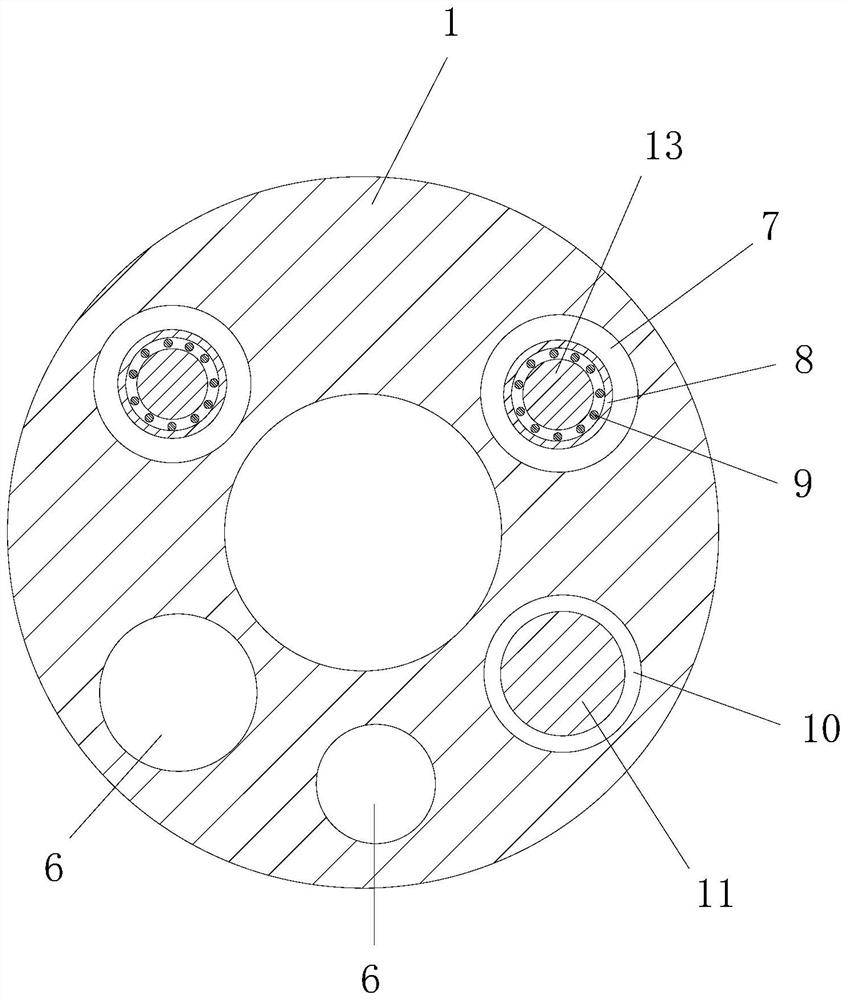

[0026] Such as figure 1 and figure 2 As shown, the working mirror carrying the induction probe according to the present invention includes a working sleeve 1 and a communication part 5 arranged at one end of the working sleeve 1, and the communication part 5 is provided with an eyepiece interface 2 communicating with the working sleeve 1, The optical fiber interface 3, the flushing water port 4, and the working sleeve 1 communicate with the eyepiece interface 2 and the optical fiber interface 3 through the connecting part 5, so that the operation or treatment of the working sleeve 1 can be observed through the eyepiece. The tube wall of the working sleeve 1 is provided with a first channel 6 through which surgical instruments can pass and a second channel 10 through which a rod-shaped sensor 11 is pierced. Both the first channel 6 and the second channel 10 work thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com