Movable type chassis, robot and vending machine

A mobile, chassis technology, applied in the direction of instruments, motor vehicles, coin-free or similar appliances, etc., can solve the problems of poor overall stability of the chassis, loss of the ability to overcome obstacles, etc., to improve the ability to overcome obstacles and adaptability, improve The effect of obstacle crossing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

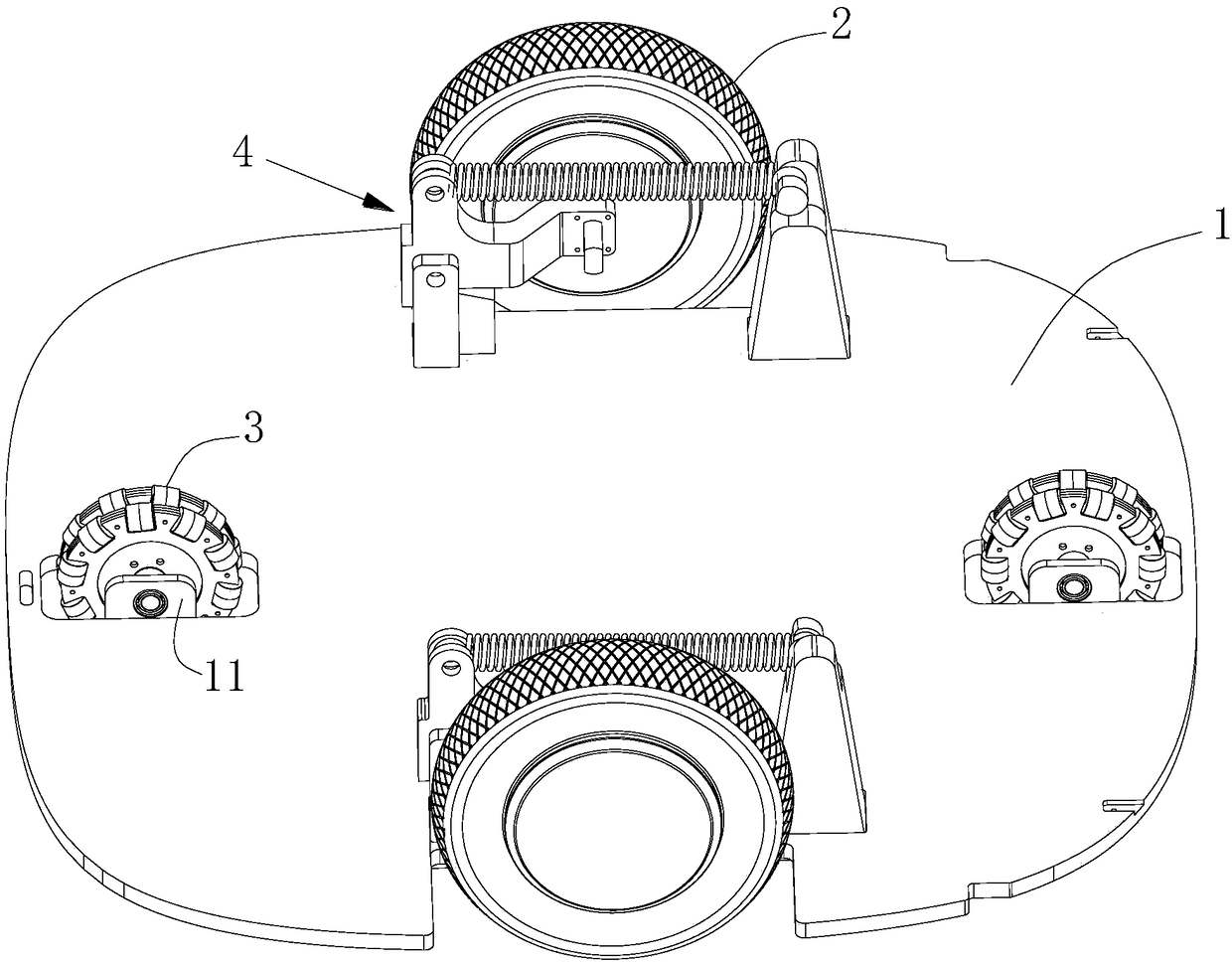

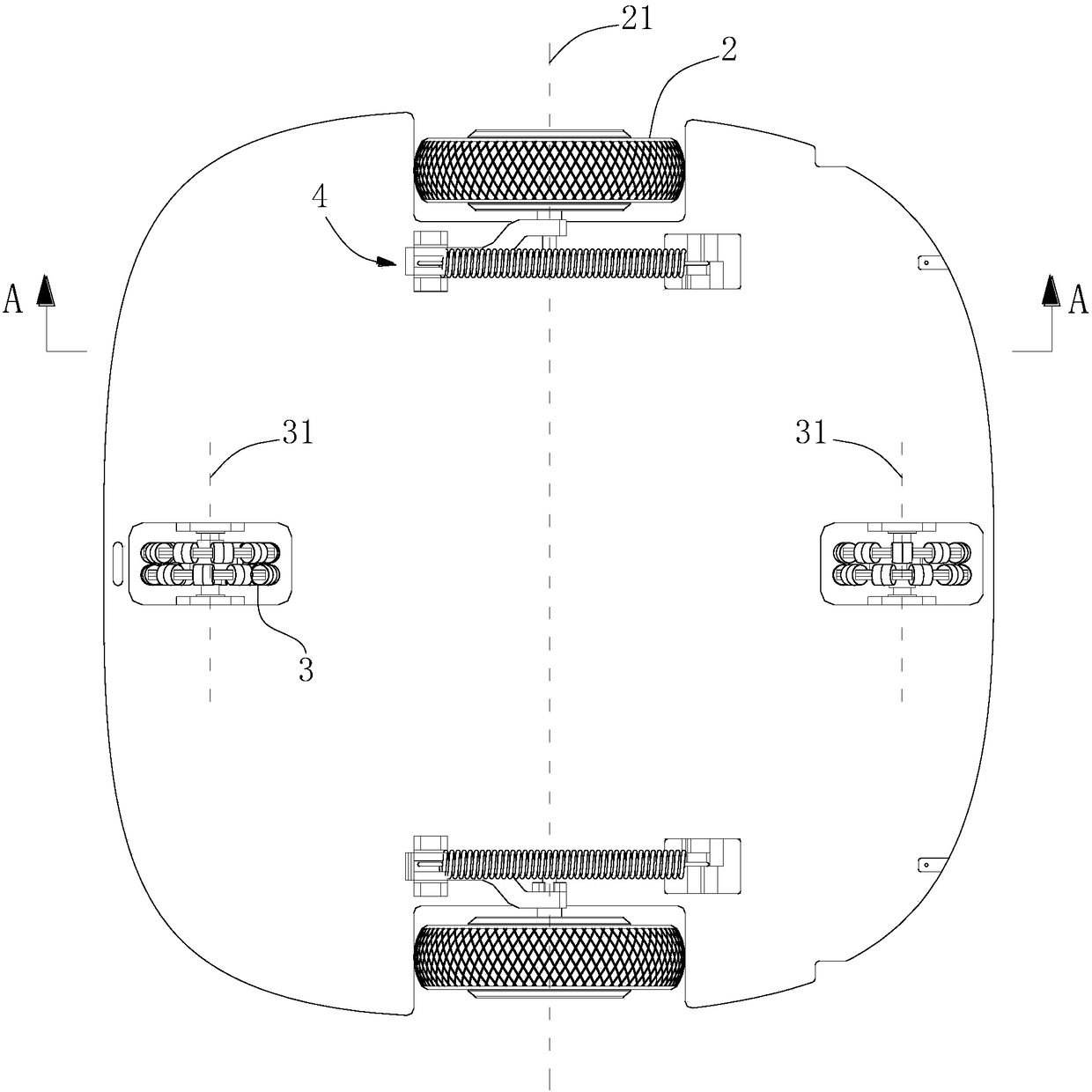

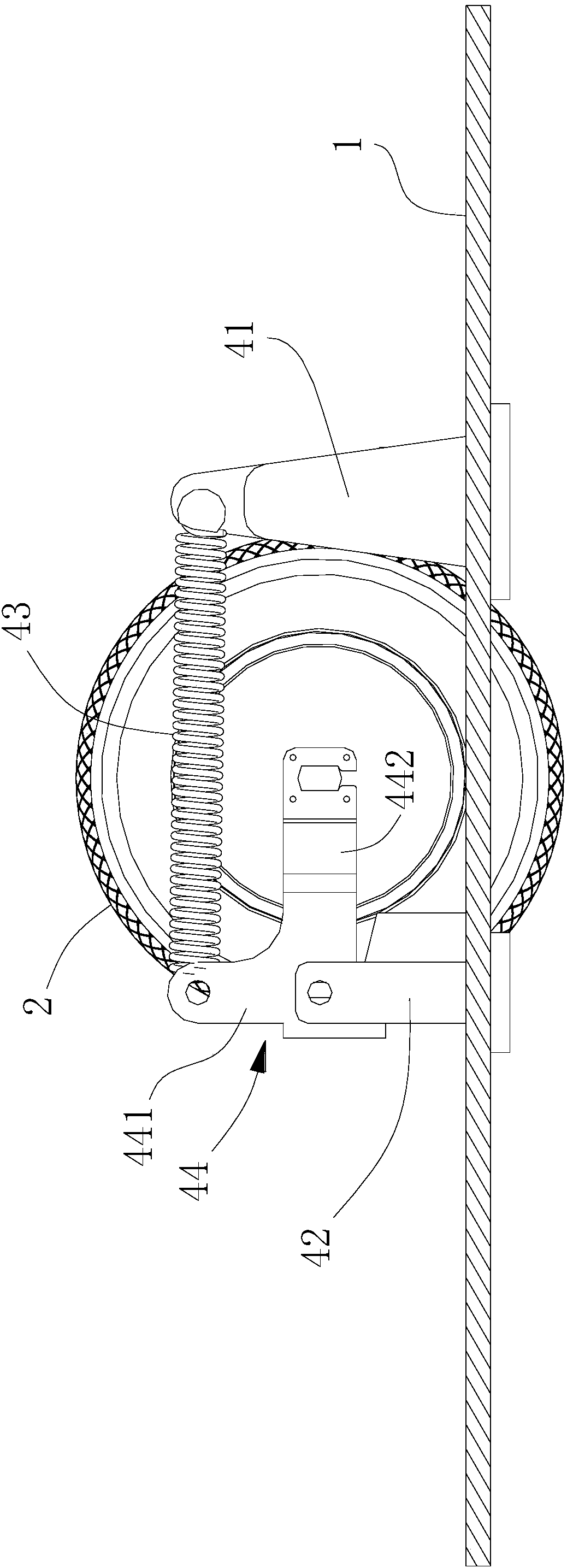

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the mobile chassis of this embodiment includes a chassis body 1, driving wheels 2 and driven wheels. There are two driving wheels 2, which are installed on the left and right sides of the chassis body 1 respectively; the driven wheels include two omni-directional wheels 3 (Omni wheels), which are respectively installed on the The front and rear sides of the chassis body 1, and the axis 31 of the omni-directional wheel is parallel to the axis 21 of the driving wheel.

[0029] Such as Figure 4 As shown, the omnidirectional wheel 3 (Omni wheel) is composed of a wheel 32 and some rollers 33 fixed on the outer periphery of the wheel 32. The axis of the wheel is perpendicular to the axis of the roller, and the wheel rotates around the axis. , the rollers are in contact with the ground in turn, and can rotate freely around their own axes. Preferably, the rollers 33 on the spokes are divided into inner ring ...

Embodiment 2

[0036]This embodiment provides a robot, which includes a mobile chassis, which is the mobile chassis described in Embodiment 1.

Embodiment 3

[0038] This embodiment provides an automatic vending machine, which includes a mobile chassis, which is the mobile chassis described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com