stabilizer bushing

A stabilizer and bushing technology, applied in the direction of springs/shock absorbers, other household appliances, transportation and packaging, etc., can solve problems such as tensile deformation and compression deformation of the main body of the bushing, and achieve the effect of improving bonding durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

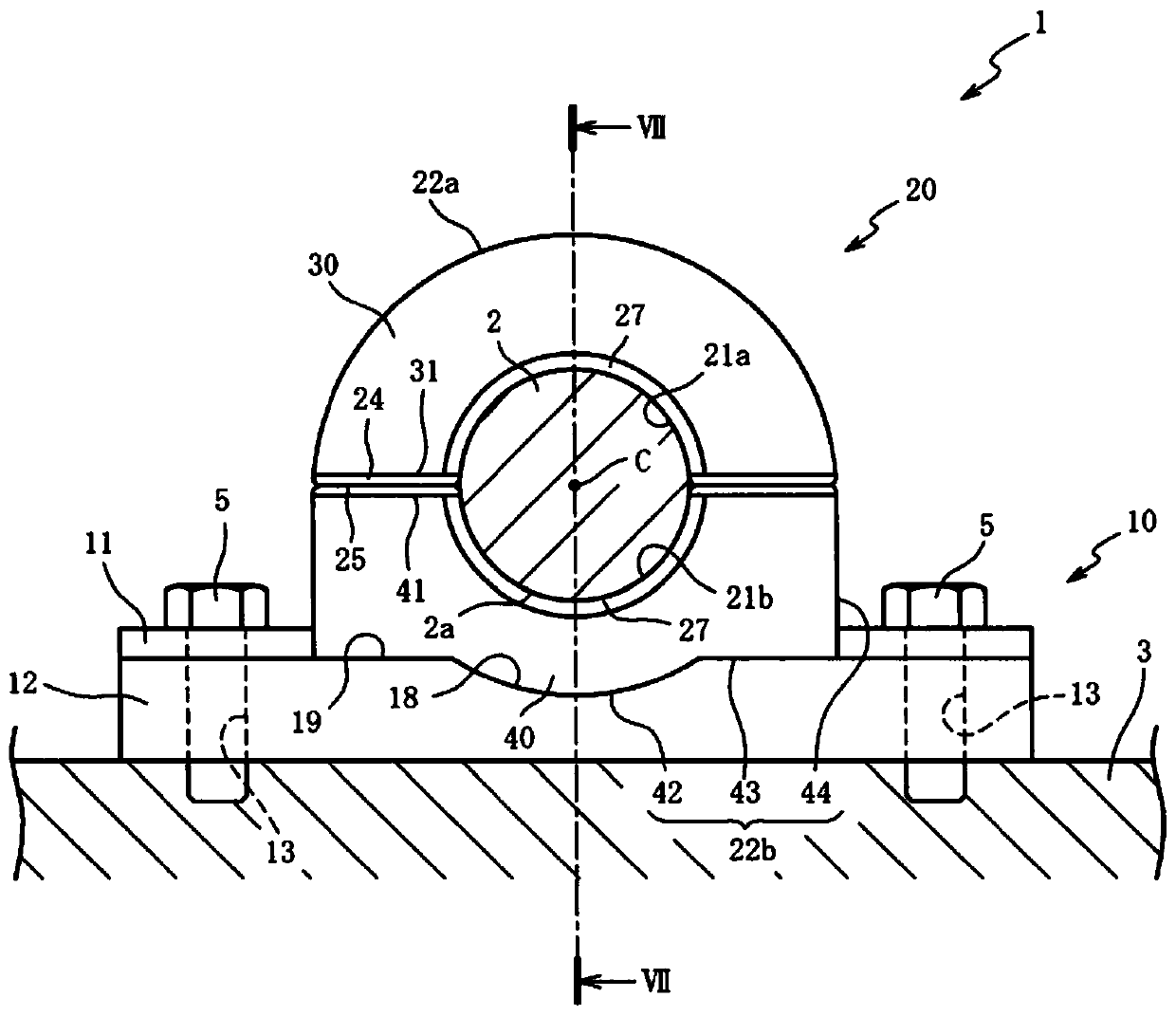

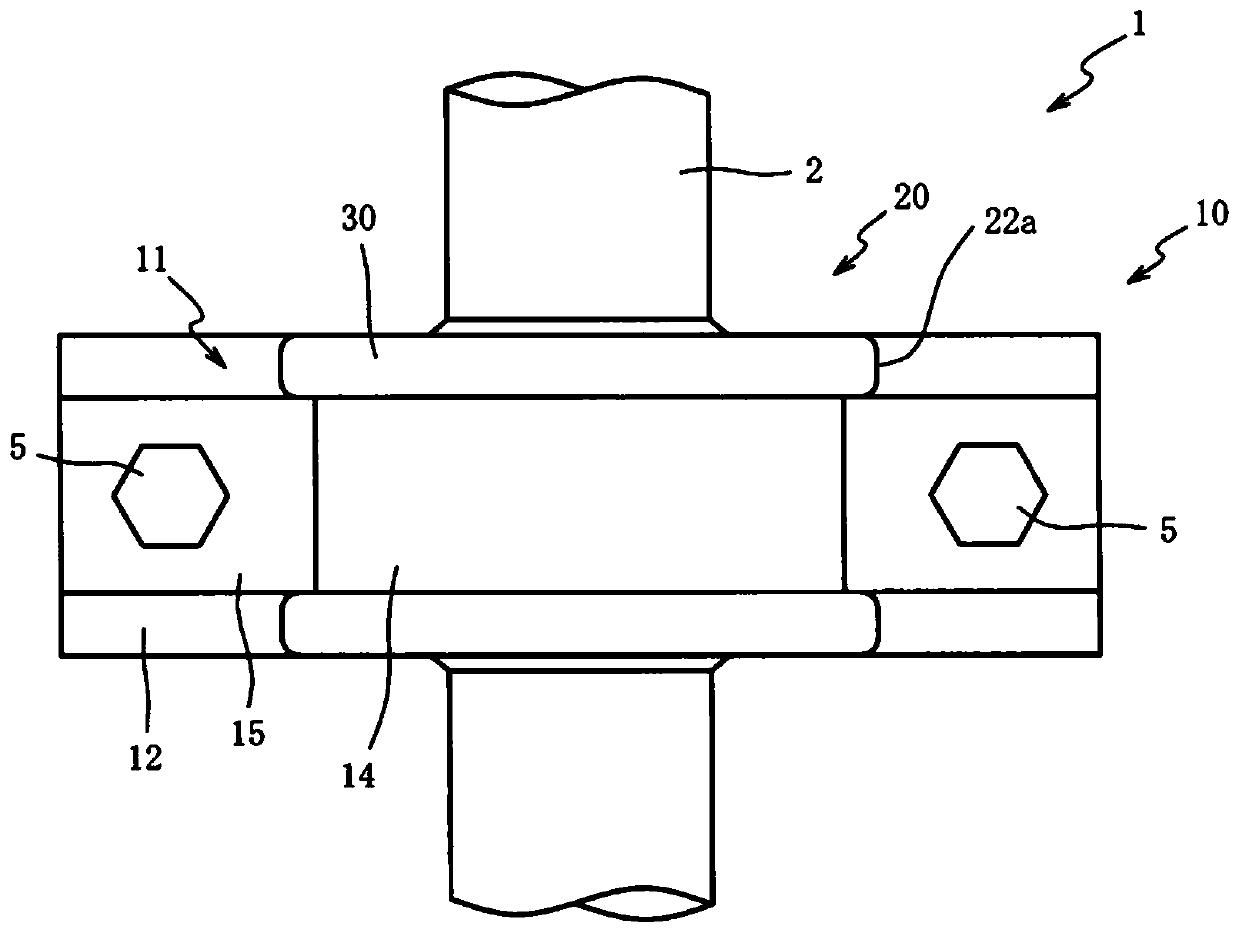

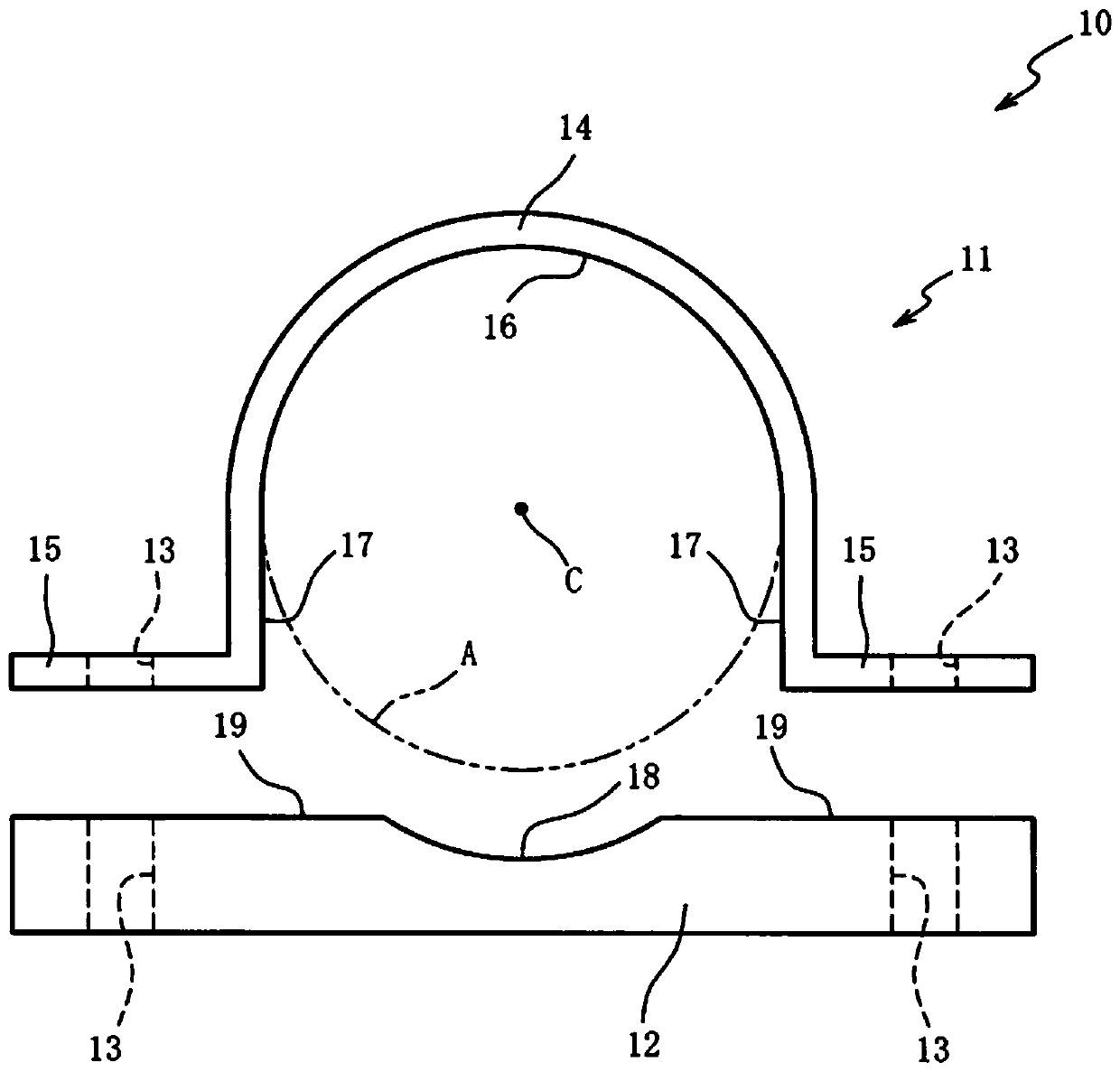

[0036] Next, preferred embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 as well as figure 2 , the stabilizer bushing 1 according to the first embodiment of the present invention will be described. figure 1 It is a front view of the stabilizer bushing 1 according to the first embodiment of the present invention. figure 2 is a top view of the stabilizer bushing 1 . In addition, in this manual, the figure 1 The up-down direction on the paper is described as the up-down direction of the stabilizer bushing 1 . The vertical direction of the stabilizer bushing 1 is opposite to the vertical direction of the vehicle.

[0037] like figure 1 as well as figure 2 As shown, the stabilizer bushing 1 elastically supports the stabilizer bar 2 on the vehicle body 3 . The stabilizer bushing 1 includes a bushing main body 20 made of a cylindrical rubber elastic body, and a bracket 10 for holding the bushing main body 20 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com