Reference device, measuring and coating device, measurement accuracy guarantee, and film manufacturing method

A technology of measuring devices and benchmarks, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of coating film thickness deviation and difficult to manage film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

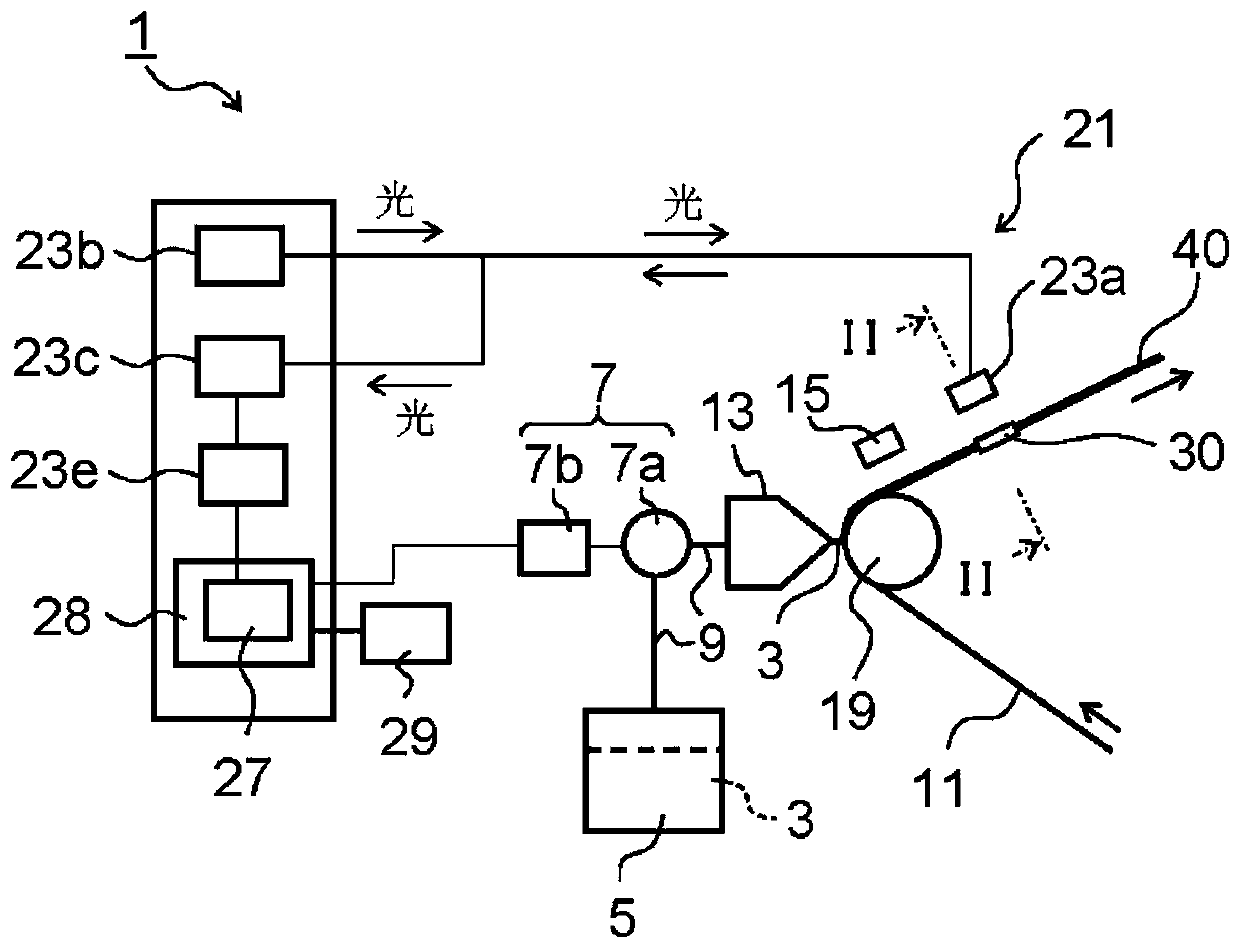

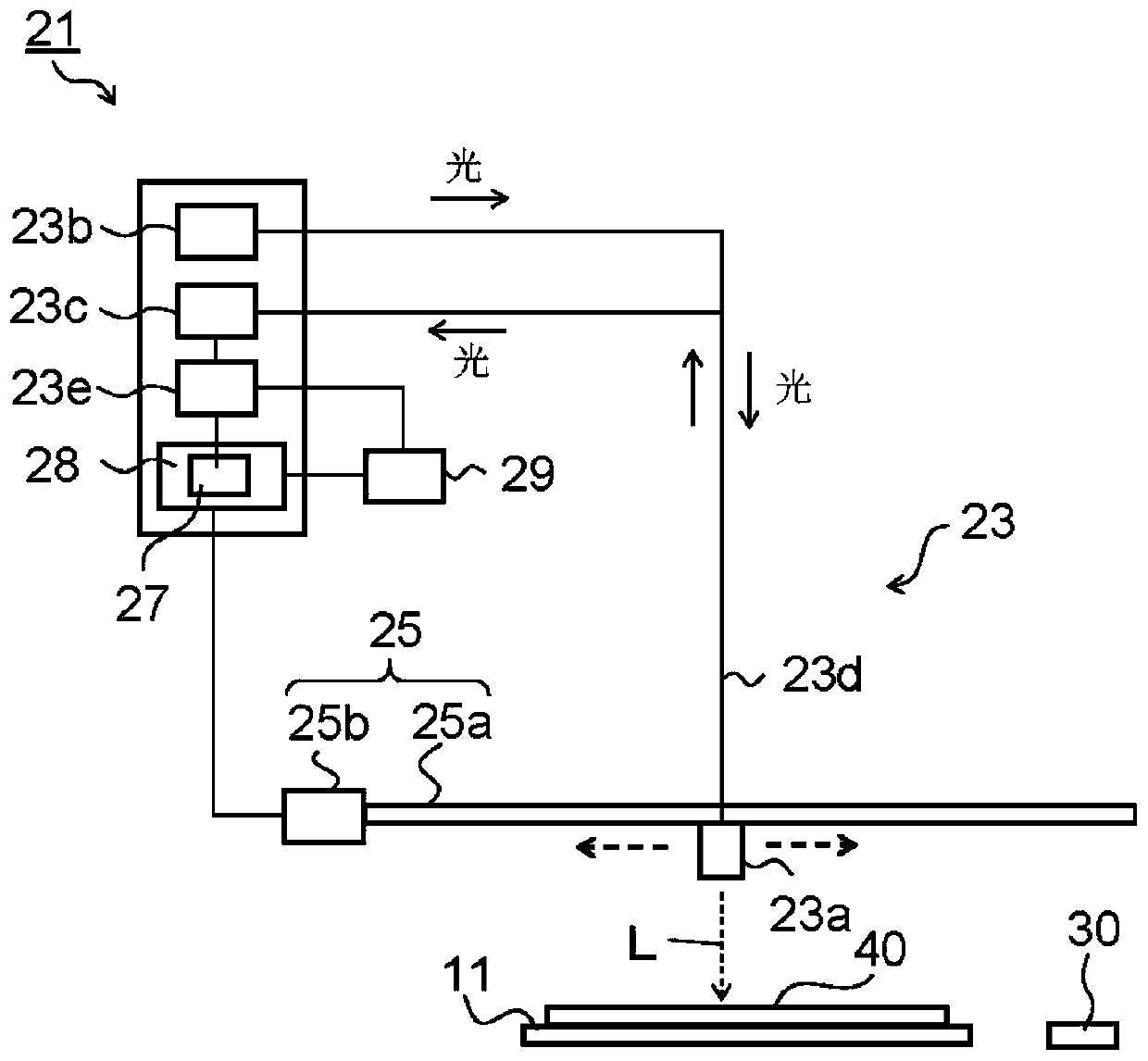

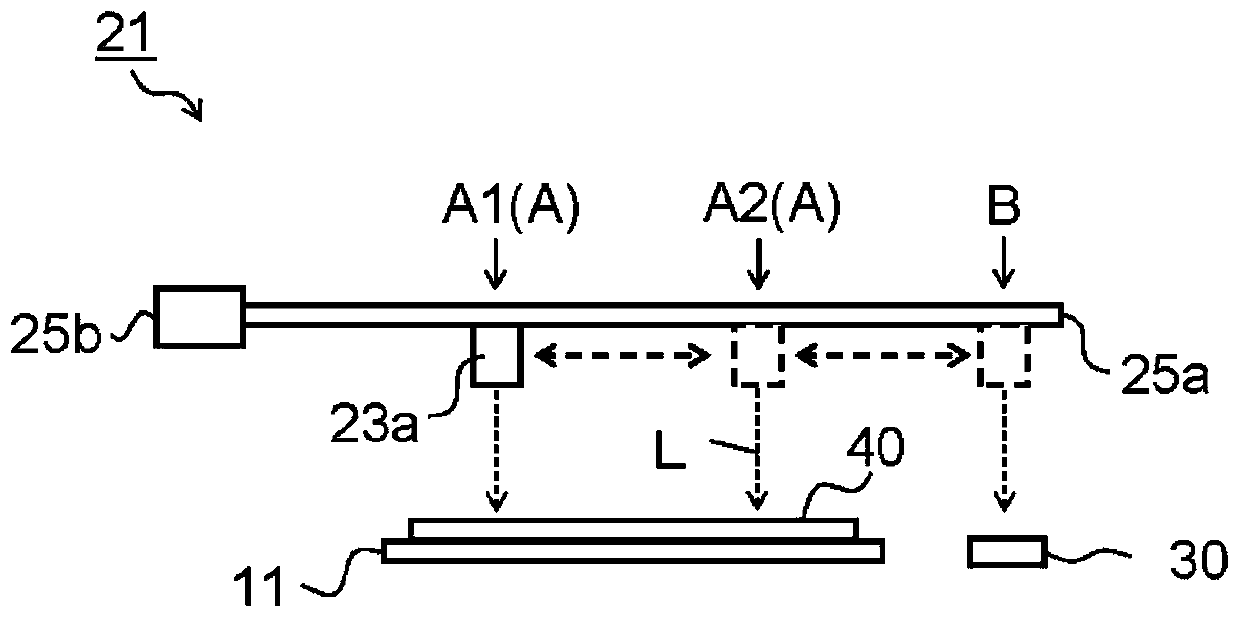

[0039] Hereinafter, a reference device according to an embodiment of the present invention, a spectroscopic interferometric measurement device using the same, a coating device, a method for ensuring measurement accuracy of a spectroscopic interferometric measurement device, and a method of manufacturing a coating film will be described with reference to the accompanying drawings. illustrate.

[0040] First, a description will be given of a coating device including a spectroscopic interferometry measuring device having a reference device according to the present embodiment as a film thickness measuring unit.

[0041] like figure 1 and figure 2As shown, the coating device 1 of this embodiment includes: a coating unit 13 that sequentially coats the coating liquid 3 onto a belt-shaped sheet that relatively moves toward the downstream side in the longitudinal direction (see the solid arrow). The coating film 40 is formed on the sheet 11; the film thickness measuring part 21 mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com