a ti-al 3 Preparation method of hollow sandwich structure of ti layered composite material

A layered composite material, ti-al3ti technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve difficult material performance flexible regulation, difficulty of Ti layered composite material, Ti layered composite material layer spacing, The layer thickness ratio is difficult to control and other problems, so as to improve the manufacturing efficiency and reduce the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

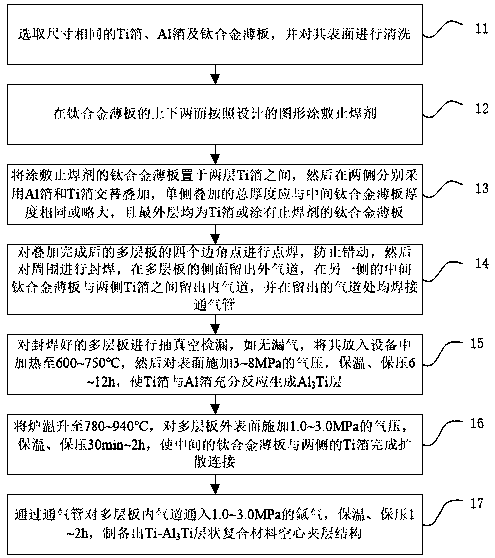

[0049] Specifically, the Ti-Al 3 The preparation method of Ti layered composite material hollow sandwich structure, such as figure 1 shown, including:

[0050] 11) Select Ti foil, Al foil and titanium alloy sheet with the same size, and clean the surface.

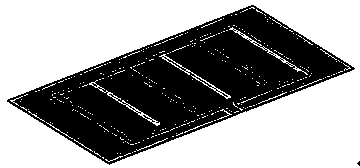

[0051] 12) Apply solder stop flux on the upper and lower sides of the titanium alloy sheet according to the designed pattern. Such as image 3 As shown, the graphics of the design are determined according to the internal structure and shape of the formed composite material.

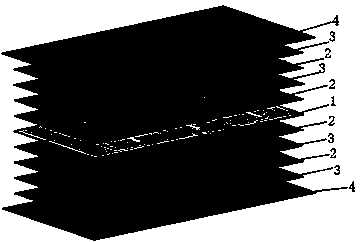

[0052] 13) Place the titanium alloy sheet coated with solder stop flux between two layers of Ti foil, and then alternately stack Al foil and Ti foil on both sides. The total thickness of one side of the stack should be the same as the thickness of the middle titanium alloy sheet Large, and the outermost layer is Ti foil or titanium alloy sheet coated with solder stop flux. Such as figure 2 As shown, the titanium alloy thin plate 1 is placed in t...

Embodiment 2

[0061] Specifically, the Ti-Al 3 The preparation method of Ti layered composite material hollow sandwich structure, such as Figure 9 shown, including:

[0062] 21) Select Ti foil, Al foil and titanium alloy sheet with the same size, and clean the surface.

[0063] 22) Take a titanium alloy thin plate coated with solder stop flux according to the designed pattern, and attach the solder stop surface to another titanium alloy thin plate of the same specification without solder stop flux. The graphic of the design is determined according to the internal structure and shape of the formed hollow structure.

[0064] 23) Seal the edge of the laminated titanium alloy sheet and leave an inner airway on the side, and weld the ventilation pipe at the inner airway.

[0065] 24) Place the laminated titanium alloy sheet between two layers of Ti foil, and then alternately stack Al foil and Ti foil on both sides, and the total thickness of one side of the stack should be the same as or sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com