A silicon carbide-based high-temperature self-lubricating composite material and its preparation method

A high-temperature self-lubricating and composite material technology, which is applied in the field of silicon carbide-based high-temperature self-lubricating composite materials and its preparation, can solve problems such as low operating temperature, achieve stable friction coefficient, improve high-temperature anti-friction and anti-wear performance, and heat resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

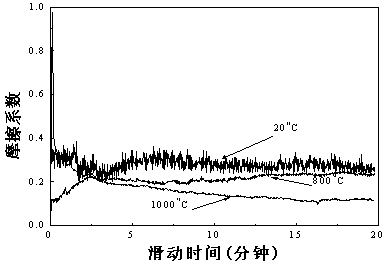

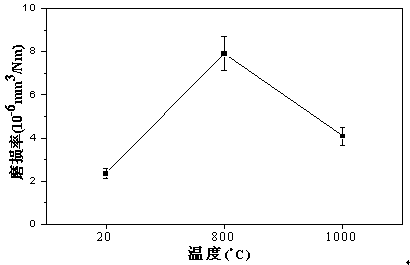

[0019] According to the mass percentage: 10% Mo, 30% CaF 2 , 60% SiC, weigh each powder material respectively. Mix in a high-energy ball mill at a speed of 200 rpm for 8 hours to obtain a composite powder, put the composite powder into a graphite abrasive tool, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: heating rate 15°C / min, furnace chamber vacuum 10 -2 ~10 -1 Pa, the sintering temperature is 1300°C, the applied pressure is 30 MPa, and the holding time is 20 min. After sintering, the material is cooled to room temperature with the furnace and taken out.

[0020] The material has a room temperature hardness of 7.31 GPa and a density of 3.99 g / cm 3 . The average coefficient of friction at room temperature is 0.24, and the wear rate is 2.05 × 10 -6 mm 3 / Nm; the average friction coefficient at 800°C is 0.46, and the wear rate is 9.87 × 10 -6 mm 3 / Nm; the average friction coefficient at 1000°C is 0...

Embodiment 2

[0022] According to the mass percentage: 25%Mo, 25%CaF 2 , 50% SiC, weigh each powder material respectively. Mix for 6 hours at a speed of 300 rpm in a high-energy ball mill to obtain a composite powder, put the composite powder into a graphite abrasive tool, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: heating rate 15°C / min, furnace chamber vacuum 10 -2 ~10 -1 Pa, the sintering temperature is 1300°C, the applied pressure is 30 MPa, and the holding time is 20 min. After sintering, the material is cooled to room temperature with the furnace and taken out.

[0023] The material has a room temperature hardness of 7.12 GPa and a density of 4.39 g / cm 3 . The average coefficient of friction at room temperature is 0.28, and the wear rate is 2.35 × 10 -6 mm 3 / Nm; the average coefficient of friction at 800°C is 0.29, and the wear rate is 7.90 × 10 -6 mm 3 / Nm; the average coefficient of friction at 1000°C ...

Embodiment 3

[0025] According to the mass percentage: 30%Mo, 20%CaF 2 , 50% SiC, weigh each powder material respectively. Mix for 4 hours at a speed of 300 rpm in a high-energy ball mill to obtain a composite powder. Put the composite powder into a graphite abrasive tool, and then place it in a vacuum hot-press sintering furnace for hot-press sintering. The sintering parameters are: heating rate 20°C / min, furnace chamber vacuum 10 -2 ~10 -1 Pa, the sintering temperature is 1200°C, the applied pressure is 20 MPa, and the holding time is 30 min. After sintering, the material is cooled to room temperature with the furnace and taken out.

[0026] The material has a room temperature hardness of 6.23 GPa and a density of 4.35 g / cm 3 . The average coefficient of friction at room temperature is 0.32, and the wear rate is 2.28 × 10 -6 mm 3 / Nm; the average coefficient of friction at 800°C is 0.25, and the wear rate is 6.88 × 10 -6 mm 3 / Nm; the average friction coefficient at 1000°C is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com