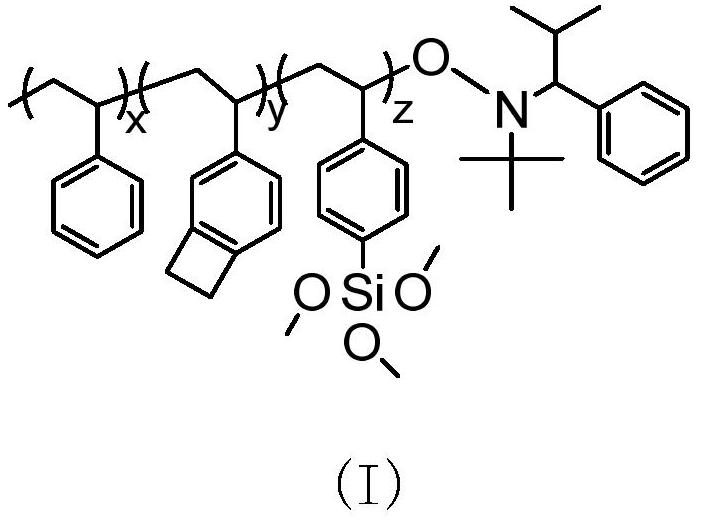

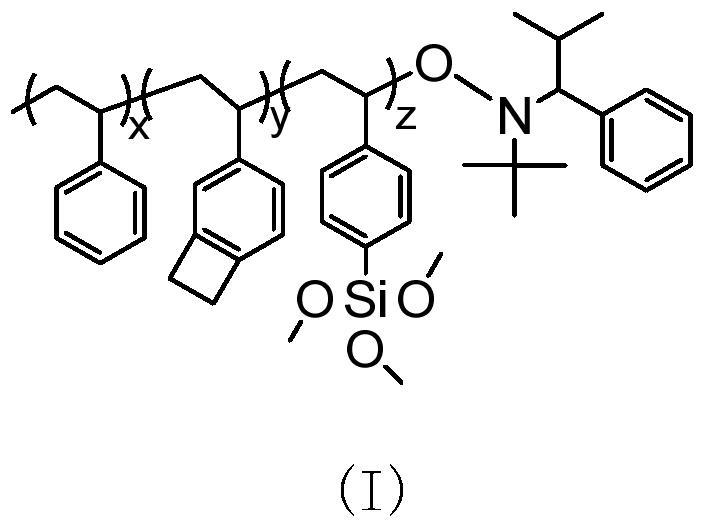

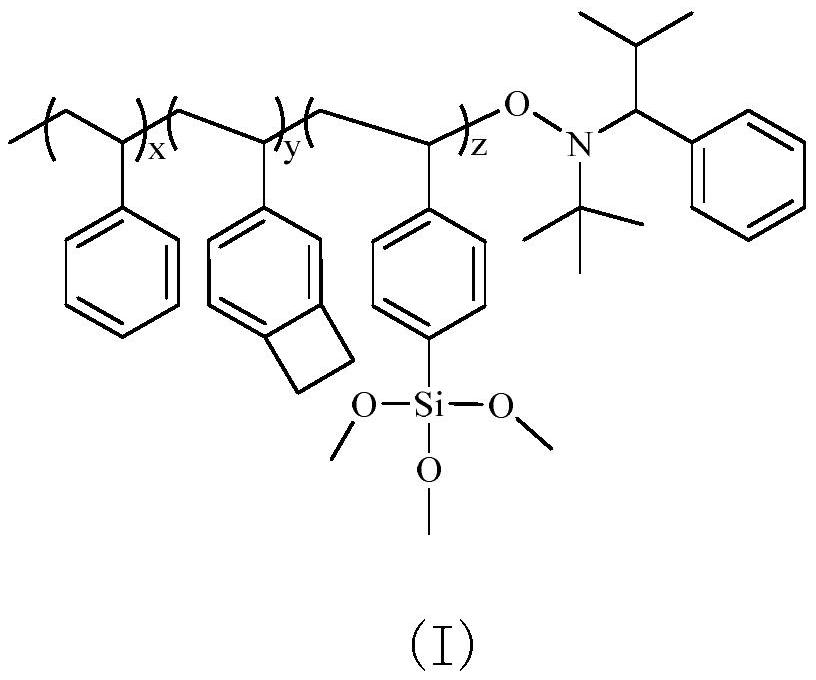

Block copolymer containing hydrolyzable siloxane, resin and preparation method thereof

A technology of block copolymer and siloxane, which is applied in the field of high molecular polymer and its preparation, can solve the problems of low dielectric performance and low performance tunability, and achieve narrow molecular weight distribution, excellent electrical performance and thermal performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of random copolymer [being called for short P (4-VBCB-co-St)], comprises the following steps:

[0041] Add 2.60 g (25 mmol) of styrene (St), 3.25 g (25 mmol) of 4-vinylbenzocyclobutene (4-VBCB) and 5 mL of dry Toluene and N-tert-butyl-N-(2-methyl-1-phenylpropyl)-O-(1-phenylethyl)hydroxylamine (0.5mmol) diluted in toluene in advance were added to the anaerobic bottle, and the mixture Freezing and pumping oxygen in a liquid nitrogen environment, and then thawing with nitrogen gas, repeat this cycle three times to ensure that the oxygen in the system has been removed. After the system returns to room temperature, raise the temperature to 90°C and stir for 18 hours, then raise the temperature to 120°C for 30 hours; after the reaction is completed, dilute the viscous reaction solution in tetrahydrofuran after the system returns to room temperature, and add the diluted solution drop by drop Precipitate in absolute ethanol, and filter the precipitate wi...

Embodiment 2

[0044] The preparation method of random copolymer [being called for short P (4-VBCB-co-St)], comprises the following steps:

[0045] Add 1.80 g (17 mmol) of styrene (St), 4.30 g (33 mmol) of 4-vinylbenzocyclobutene (4-VBCB), 5 mL of dry Toluene and N-tert-butyl-N-(2-methyl-1-phenylpropyl)-O-(1-phenylethyl)hydroxylamine (0.5mmol) diluted in toluene in advance were added to the anaerobic bottle, and the mixture Freezing and pumping oxygen in a liquid nitrogen environment, and then thawing with nitrogen gas, repeat this cycle three times to ensure that the oxygen in the system has been removed. After the system returned to room temperature, the system was heated up to 90°C and stirred for 18 hours, then raised to 120°C for 30 hours. After the reaction was completed and the system returned to room temperature, the viscous reaction solution was diluted in tetrahydrofuran, and the diluted solution was added dropwise in absolute ethanol for precipitation, and the precipitate was fil...

Embodiment 3

[0047] The preparation method of random copolymer [being called for short P (4-VBCB-co-St)], comprises the following steps:

[0048] Add 0.83g (8mmol) of styrene (St), 5.5g (42mmol) of 4-vinylbenzocyclobutene (4-VBCB), 5mL of dry Toluene and N-tert-butyl-N-(2-methyl-1-phenylpropyl)-O-(1-phenylethyl)hydroxylamine (0.5mmol) diluted in toluene in advance were added to the anaerobic bottle, and the mixture Freezing and pumping oxygen in a liquid nitrogen environment, and then thawing with nitrogen gas, repeat this cycle three times to ensure that the oxygen in the system has been removed. After the system returned to room temperature, the system was heated up to 90°C and stirred for 18 hours, then raised to 120°C for 30 hours. After the reaction was completed and the system returned to room temperature, the viscous reaction solution was diluted in tetrahydrofuran, and the diluted solution was added dropwise in absolute ethanol for precipitation, and the precipitate was filtered w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com