Ibuprofen-loaded praziquantel composite particle and preparation method thereof

A technology of composite granules and praziquantel, which is applied in the direction of pharmaceutical formulations, drug combinations, and medical preparations containing active ingredients, etc., and can solve problems such as low bioavailability, poor product powder performance, and impact on clinical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) At 70°C, prepare an aqueous solution with a concentration of ibuprofen of 0.01g / mL and a concentration of praziquantel of 0.002g / mL, and stir until layering occurs and the oil droplets of ibuprofen-containing praziquantel are uniform in water distributed;

[0037] (2) Cool the solution to 1°C at a cooling rate of 70°C / 10min, and maintain a stirring power per unit volume of 0.989kW / m 3 To crystal out, add surfactant sodium stearate 0.02% (based on the quality of ibuprofen-carrying praziquantel-water mixed solution) under this temperature condition. Stir continuously for 0.5h to make the crystals coalesce into compact particles;

[0038] (3) Vacuum filtration, washing with water, and drying at normal pressure at 25° C. for 12 hours to obtain the praziquantel product contained in ibuprofen.

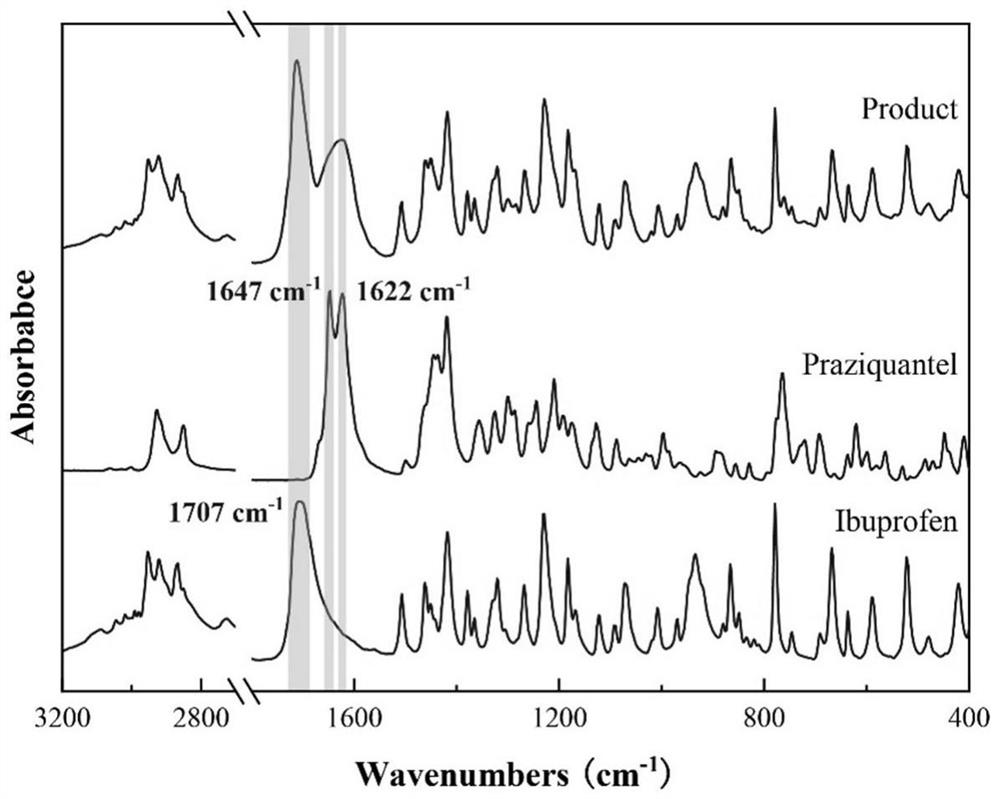

[0039] The solid infrared absorption spectrum of product (instrument model ALPHA, Bruker, Germany) sees figure 1 , in the infrared spectrum of the product (product) at 1707cm ...

Embodiment 2

[0044] (1) At 80°C, prepare an aqueous solution with a concentration of ibuprofen of 0.01 g / mL and a concentration of praziquantel of 0.005 g / mL, and stir until layering occurs and the oil droplets of ibuprofen-containing praziquantel are uniform in water distributed;

[0045] (2) Cool the solution to 5°C at a cooling rate of 60°C / 10min, and maintain a stirring power per unit volume of 0.358kW / m 3 To crystal out, add surfactant sodium hexametaphosphate 0.15% (based on the quality of ibuprofen-carrying praziquantel-water mixed solution) under this temperature condition. Continue to stir for 2 hours to make the crystals coalesce into compact particles;

[0046] (3) Vacuum filtration, washing with water, and drying at 40° C. under normal pressure for 24 hours to obtain the praziquantel product contained in ibuprofen.

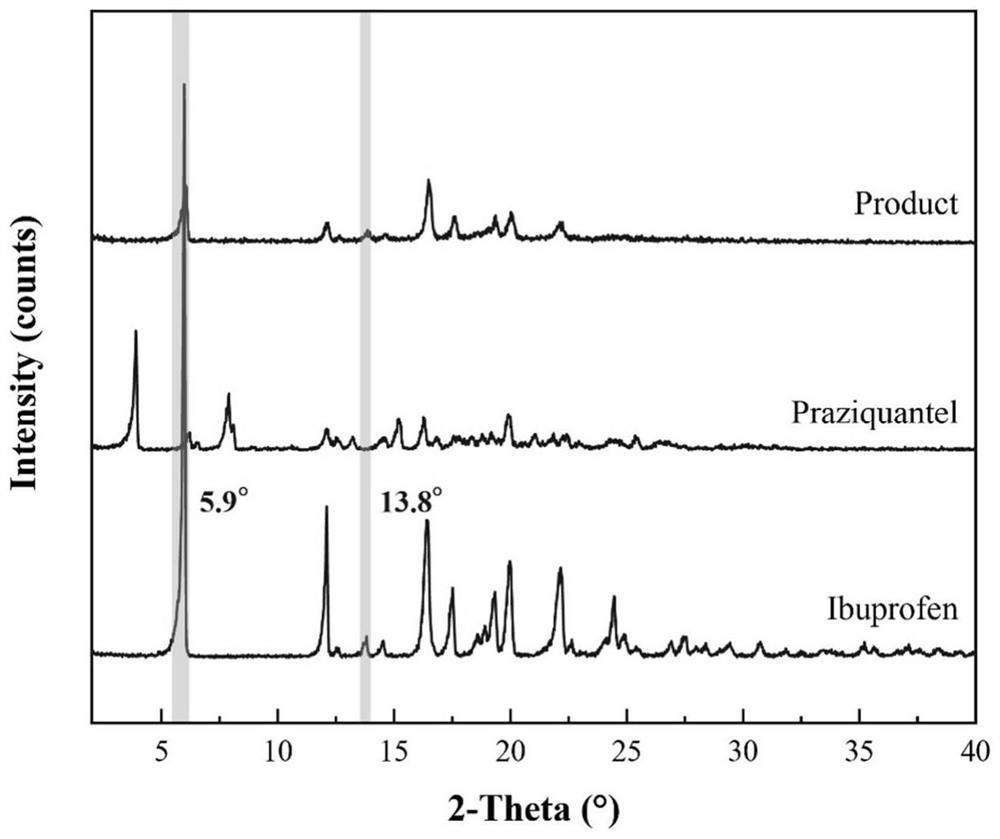

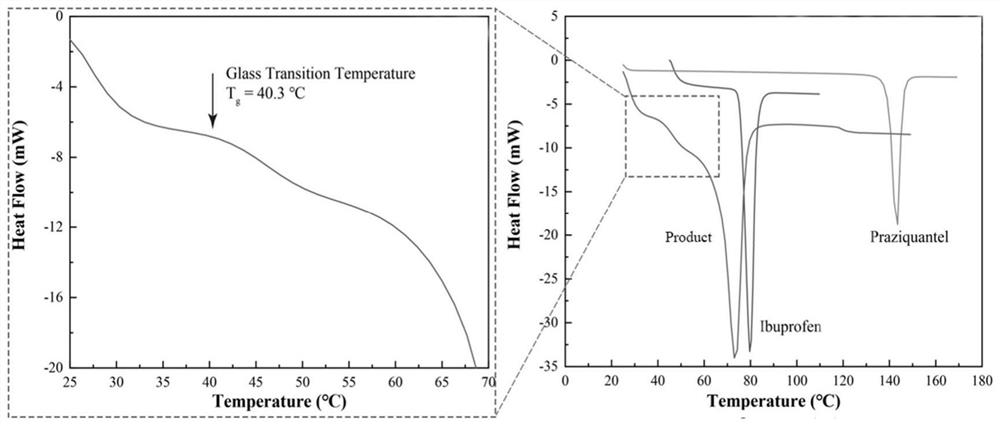

[0047] According to the results of the solid infrared absorption spectrum, PXRD spectrum and differential scanning calorimetry spectrum of the product (test meth...

Embodiment 3

[0049] (1) At 90°C, prepare an aqueous solution with a concentration of ibuprofen of 0.01 g / mL and a concentration of praziquantel of 0.01 g / mL, and stir until layering occurs and the oil droplets of ibuprofen-containing praziquantel are uniform in water distributed;

[0050] (2) Cool the solution to 10°C at a cooling rate of 50°C / 10min, and maintain a stirring power per unit volume of 0.138kW / m 3 To crystal out, add surfactant sodium dodecylbenzene sulfonate 0.40% (based on the quality of ibuprofen-carrying praziquantel-water mixed solution) under this temperature condition. Continue to stir for 3 hours to make the crystals coalesce into compact particles;

[0051] (3) Vacuum filtration, washing with water, and drying at normal pressure at 50° C. for 36 hours to obtain the praziquantel product contained in ibuprofen.

[0052] According to the results of the solid infrared absorption spectrum, PXRD spectrum and differential scanning calorimetry spectrum of the product (test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com