Titanium-aluminum intermetallic compound-based self-lubricating composite material and preparation method thereof

A technology of intermetallic compounds and composite materials, which is applied in the field of titanium-aluminum intermetallic compound-based self-lubricating composite materials and its preparation, can solve the problems that the lubrication performance does not meet the requirements of practical applications, the hardness and strength of materials are low, and the composition of materials is complex. Achieve the effect of short sintering time, low wear rate and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides the preparation method of the titanium-aluminum intermetallic compound-based self-lubricating composite material, which is characterized in that it comprises the following steps:

[0027] (1) Take titanium-aluminum intermetallic compound powder and copper-clad graphite powder respectively, mix uniformly by mechanical ball mill;

[0028] (2) The mixture in step (1) is sintered by a spark plasma sintering method, and naturally cooled to room temperature after sintering to obtain a titanium-aluminum intermetallic compound-based self-lubricating composite material.

[0029] In one embodiment, the sintering process parameters are: the degree of vacuum is 10 -3 -10 -1 Pa; heating rate is 80-100°C / min, preferably 90-100°C / min; sintering temperature is 1000-1150°C, preferably 1050-1150°C; applied pressure is 30-40MPa; holding time is 10-15min.

[0030] In the present invention, the sintering parameters of rapid temperature rise and short si...

Embodiment 1

[0039] According to mass percentage, weigh 90% titanium-aluminum intermetallic compound powder (particle size is 85 μ m; Mole percentage is: 50% Ti, 46% Al, 2% Cr, 2% Nb) and 10% copper clad graphite powder (Cu The mass ratio of graphite and graphite is 1:1, the particle size is 350 mesh), the mixed powder is obtained by mechanical ball milling, and then the mixed powder is placed in a spark plasma sintering furnace for sintering, and the sintering parameters adopted are: the degree of vacuum is 5×10 -2 Pa, the heating rate is 90°C / min, the sintering temperature is 1050°C, the applied pressure is 35MPa, and the holding time is 10min. After the sintering is completed, it is cooled to room temperature with the furnace to obtain a titanium-aluminum intermetallic compound-based self-lubricating composite material.

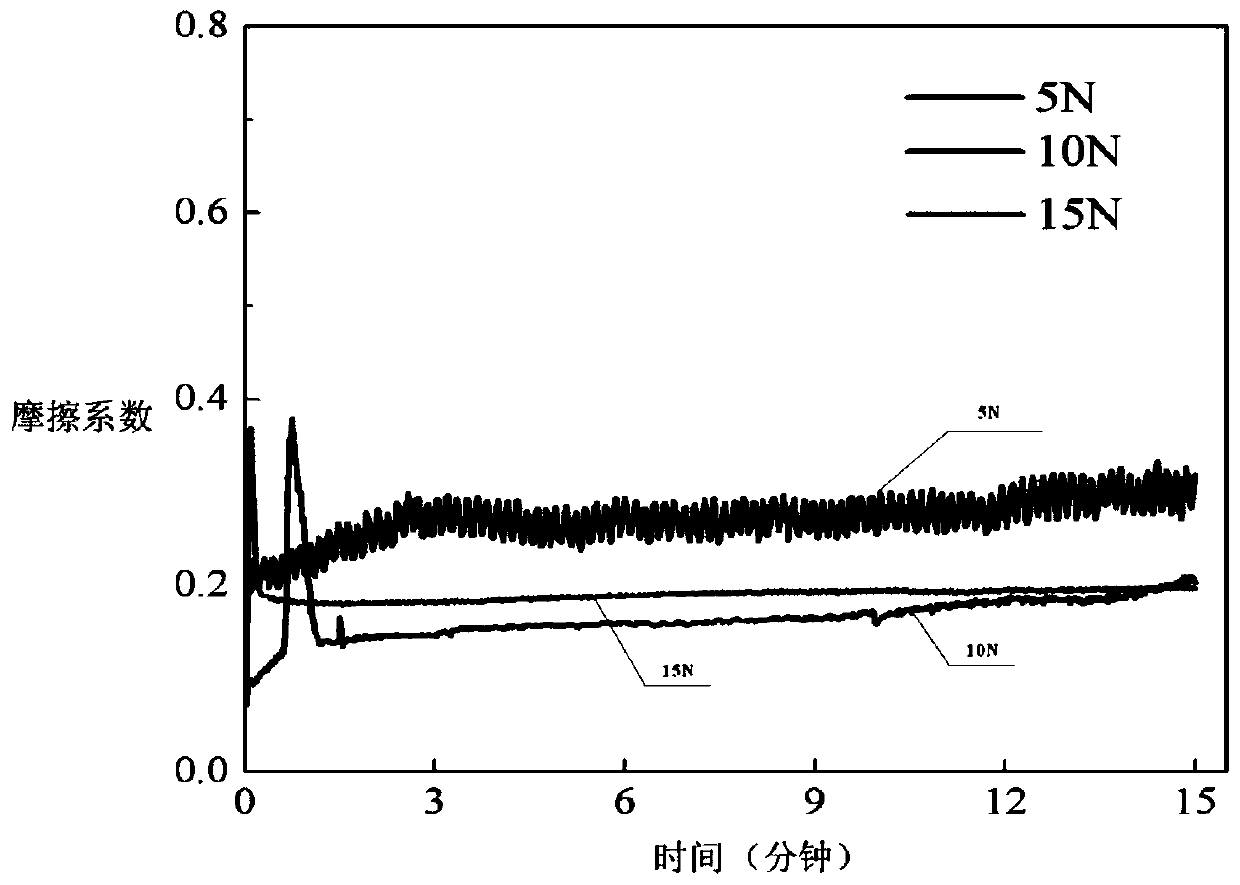

[0040] The friction coefficient of the self-lubricating composite material is small, 0.30, and the data is stable, and its wear rate is 4.75×10 -4 mm 3 N -1 m -1 ,...

Embodiment 2

[0042]According to mass percentage, weigh 80% titanium-aluminum intermetallic compound powder (particle size is 100 μ m; Mole percentage is: 50% Ti, 46% Al, 2% Cr, 2% Nb) and 20% copper clad graphite powder (Cu The mass ratio of graphite to graphite is 1:1, and the particle size is 250 meshes). The mixed powder is obtained by mechanical ball milling, and then the mixed powder is placed in a spark plasma sintering furnace for sintering. The sintering parameters used are: the degree of vacuum is 1×10 -3 Pa, the heating rate is 100°C / min, the sintering temperature is 1150°C, the applied pressure is 30MPa, and the holding time is 15min. After the sintering is completed, it is cooled to room temperature with the furnace to obtain a titanium-aluminum intermetallic compound-based self-lubricating composite material.

[0043] The friction coefficient of the self-lubricating composite material is small, 0.29, and the data is stable, and its wear rate is 3.46×10 -5 mm 3 N -1 m -1 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com