A kind of preparation method of large-scale crystalline silicon particles

A crystalline silicon, large-scale technology, used in the field of semiconductor special structure preparation, can solve problems such as inlay, achieve the effects of high dispersion, expanded application range, and simple pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

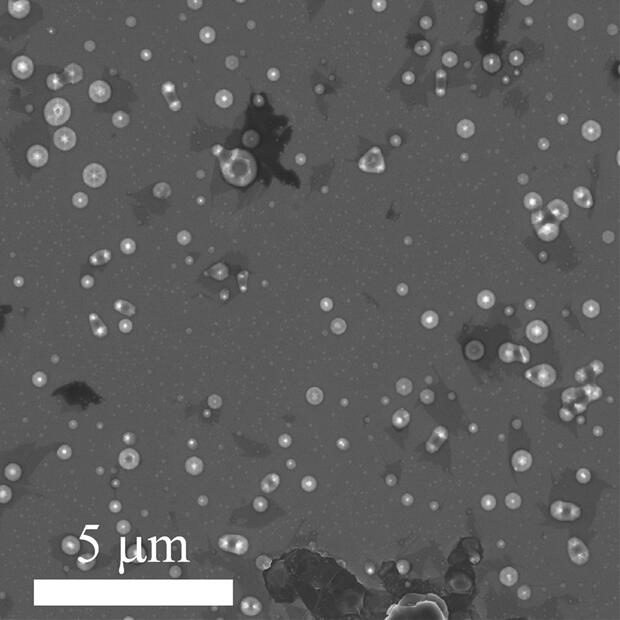

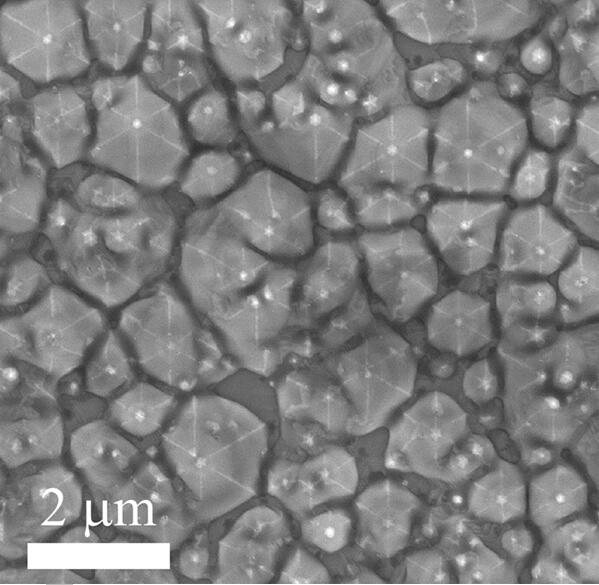

Image

Examples

preparation example Construction

[0038] A method for preparing large-scale crystalline silicon particles, the crystalline silicon particles are grown on the surface of single crystal silicon carbide, the preparation method comprises the following steps:

[0039] S100: Perform heat treatment on the single crystal silicon carbide wafer; the heat treatment is performed in a sealed environment, and the sealed environment is filled with a first gas; during the heat treatment, the pressure of the sealed environment is maintained at 1 atm - 20atm. It should be noted that filling the sealed environment with the first gas can be performed before placing the single crystal silicon carbide wafer, or after placing the single crystal silicon carbide wafer. Before filling the first gas, the sealed environment can be cleaned with the first gas for 1 to 3 times, and then filled with the first gas to make the sealed environment reach the required preset pressure and stop filling the first gas. That is to say, the first gas i...

Embodiment 1

[0062] S001: Take a 6H-SiC silicon carbide wafer that has been cleaned with hydrofluoric acid, deionized water, acetone and ethanol in sequence, dry it with a nitrogen gun, put it into a crucible, and put it into a tube furnace together.

[0063] S002: Purge the tube furnace with argon for more than three times, and then inject argon at a flow rate of 10 mL / min to bring the pressure of the tube furnace to 20 atm, and then stop argon.

[0064] S100: After the program starts, the tube furnace starts to heat up. During the temperature rise process, the valve on the right side of the tube furnace is adjusted every 30 minutes to keep the pressure at 20 atm. In this step, the heating rate is 1° C. / min.

[0065] S200: When the temperature in the tube furnace rises to 2000 °C, keep it warm for 100 h.

[0066] S310: After the heat preservation is over, the tube furnace starts to cool down according to the program. At this time, adjust the pressure inside the tube furnace to 15 atm and...

Embodiment 2

[0071] S001: Take out a 4H-SiC silicon carbide wafer cleaned with hydrofluoric acid, deionized water, acetone and ethanol, dry it with a nitrogen gun, put it into a crucible, and put it into a tube furnace together.

[0072] S002 Clean the tube furnace with argon for more than three times, and then feed a mixture of helium and argon (95% argon and 5% helium) at a flow rate of 20 L / min, so that the pressure of the tube furnace reaches 1 atm, Then stop feeding the mixture.

[0073] S100: After the program starts, the tube furnace starts to heat up. During the heating process, adjust the valve on the right side of the tube furnace every 10 minutes to keep the pressure at 1 atm. In this step, the heating rate is 5° C. / min.

[0074] S200: When the temperature inside the tube furnace rises to 500 °C, keep it warm for 1 s.

[0075] S310: After the heat preservation is over, the tube furnace starts to cool down according to the program. At this time, adjust the pressure in the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com