Multi-directional upender

A turning machine, multi-directional technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of elevator only with lifting function, low clamping efficiency, single function, etc., to achieve low cost, improve efficiency and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

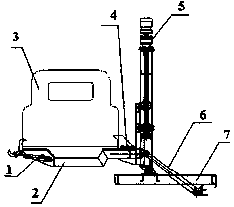

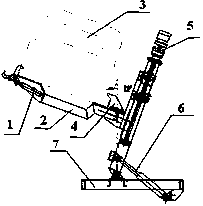

[0015] see Figure 1 to Figure 3 As shown, the present invention includes a frame 9, a base 7, a clamping mechanism 2, a lifting mechanism 4 and an overturning mechanism, the lifting mechanism 4 is connected with the frame 9 through a mechanical mechanism, and the clamping mechanism 2 is fastened The device is fastened together with the lifting mechanism 4, and the turning hydraulic cylinder 6 is arranged on the turning mechanism. One end is fixed together with base 7, and described frame 9 is fixed on the base 7 by a rotating mechanism, therefore, described frame 9 can rotate with leading screw 8, and described control mechanism is arranged on the top of frame 9, in The control mechanism is provided with a motor 5, the main shaft of the motor 5 is connected with a vertically installed lead screw 8, and the other end of the lead screw 8 is connected with the rotating mechanism. The clamping mechanism 2 is provided with a mechanism hydraulic cylinder 1 . A guide device 10 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap