Correction device applicable to shakeproof strip fulcrum and distortion

A technology of correction device and anti-vibration bar, which is applied in the field of parts processing, can solve the problems of wasting raw materials, large processing volume, uncontrollable parts distortion, etc., and achieve the effects of avoiding pollution, improving work efficiency and reducing springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

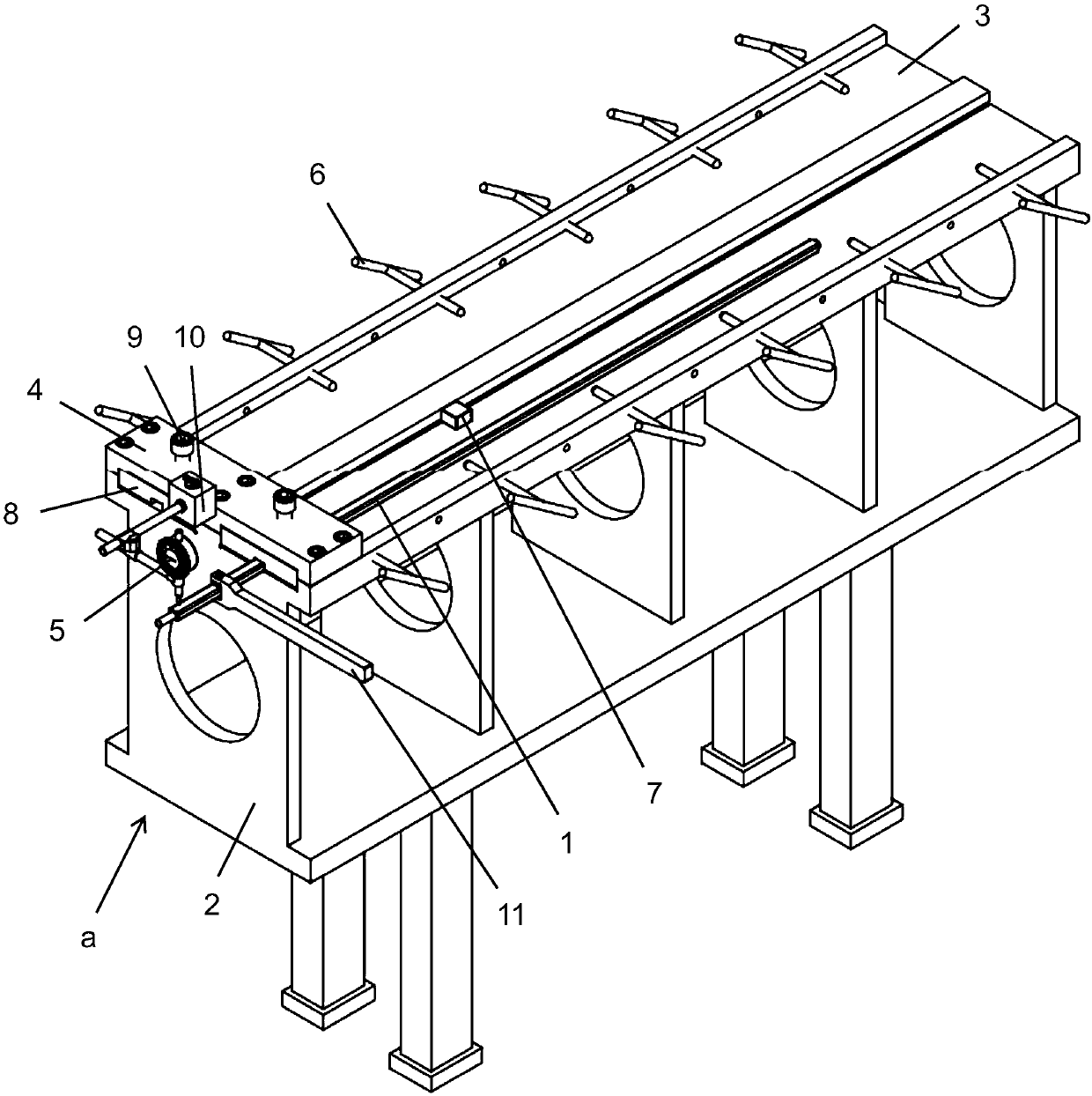

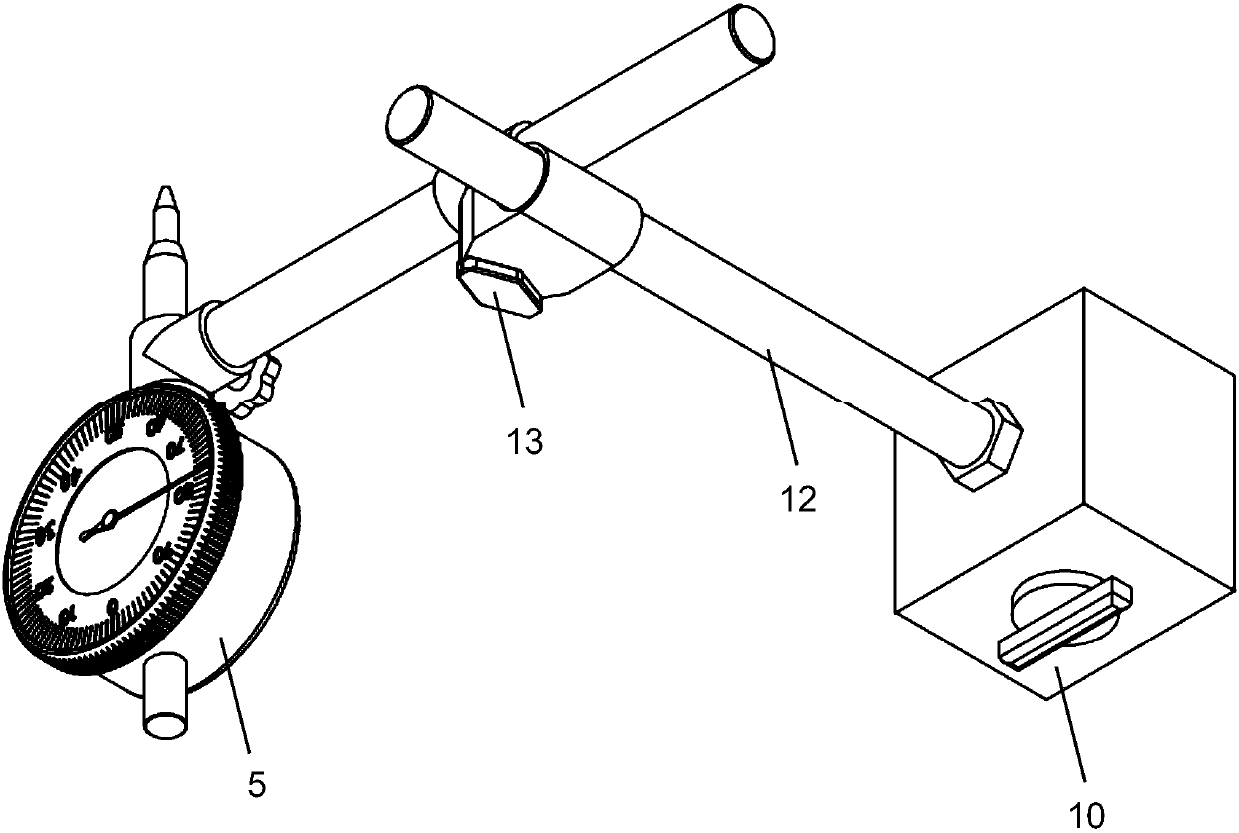

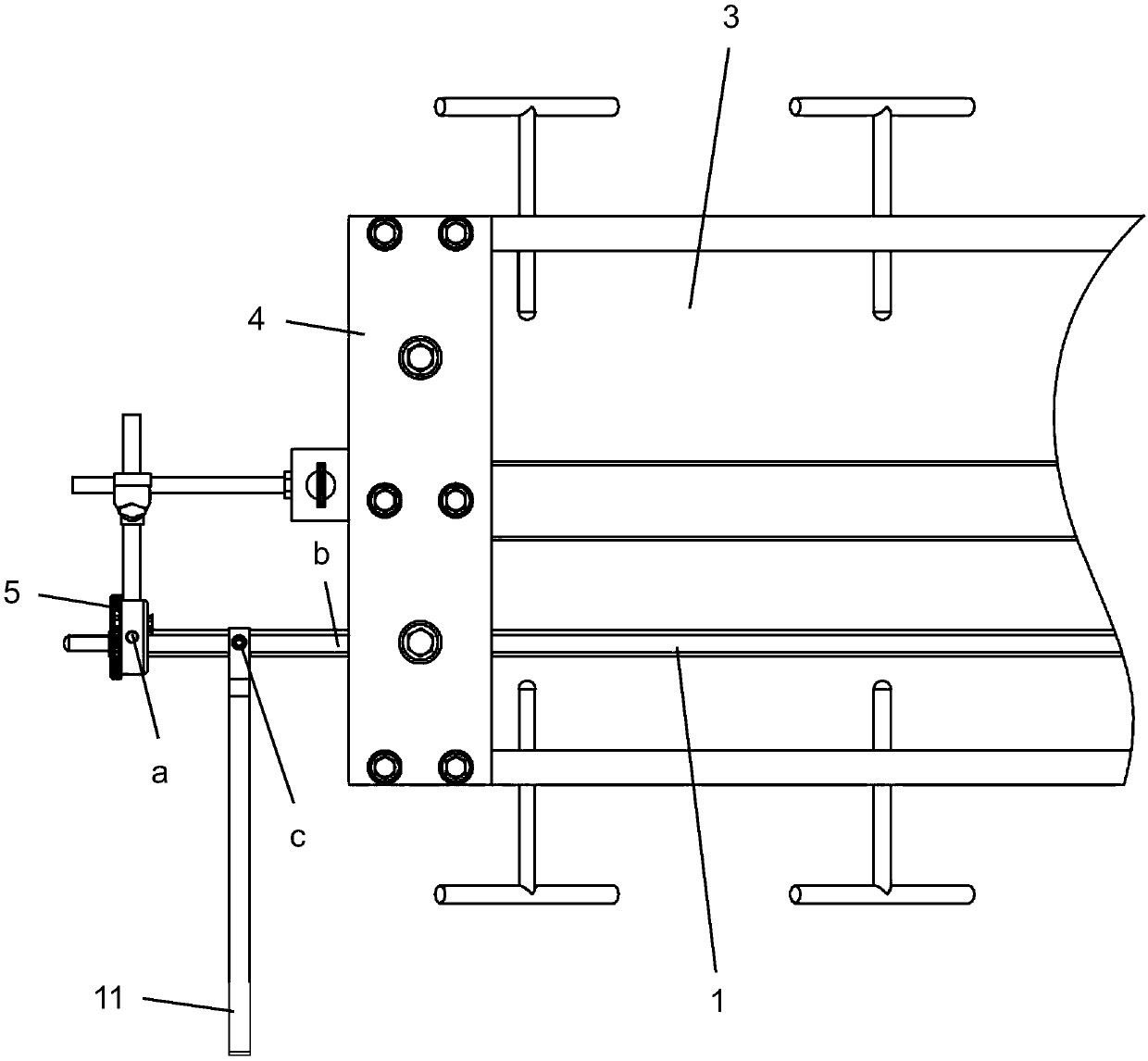

[0030] Please combine Figure 1 to Figure 6 As shown, a correction device suitable for the fulcrum and distortion of the anti-vibration strip provided by the present invention combines two modules of straightening and distortion correction of the anti-vibration strip 1 into one, including a platform bracket 2, a correction platform 3, an upper Pressing plate 4, measuring device 5, correction handle 6 and straightening fulcrum 7, correction platform 3 is arranged on the top of platform support 2, in this embodiment, two working stations are provided on correction platform 3, can carry out correction work at the same time, There are several correction handles 6, which are respectively arranged on both sides of the correction platform 3, corresponding to two working stations. The correction handle 6 exerts force on the anti-vibra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap