Machining method of special-shaped part

A processing method and technology for special-shaped parts, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inconvenient clamping, many processes, and easy to vibrate during processing, so as to reduce the number of clamping, Solve the effect of many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

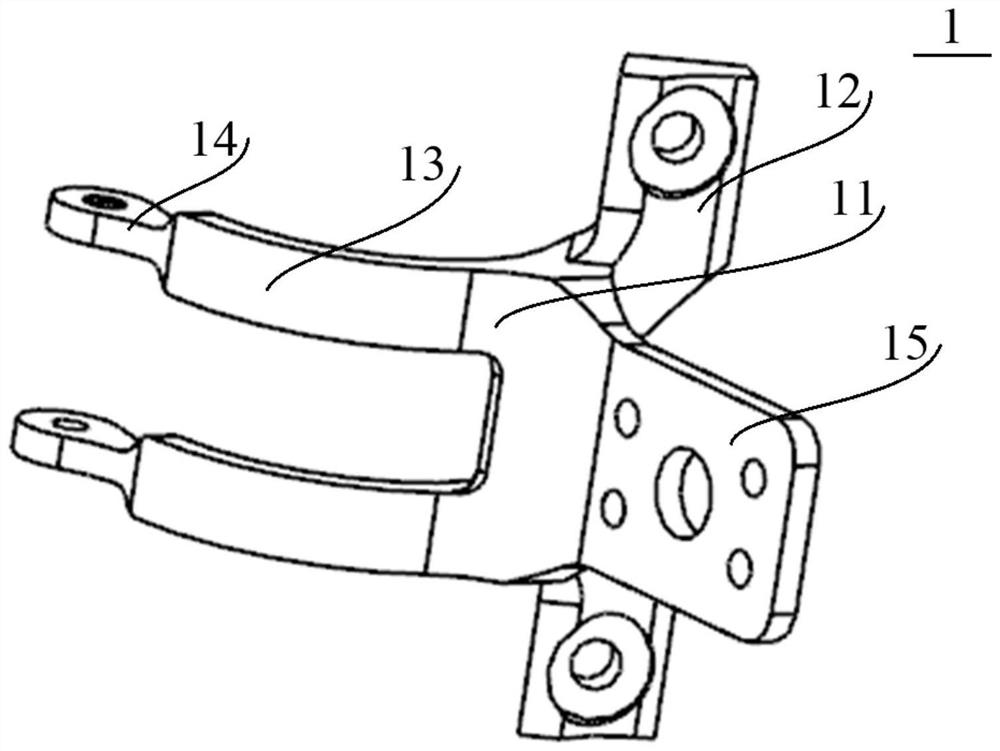

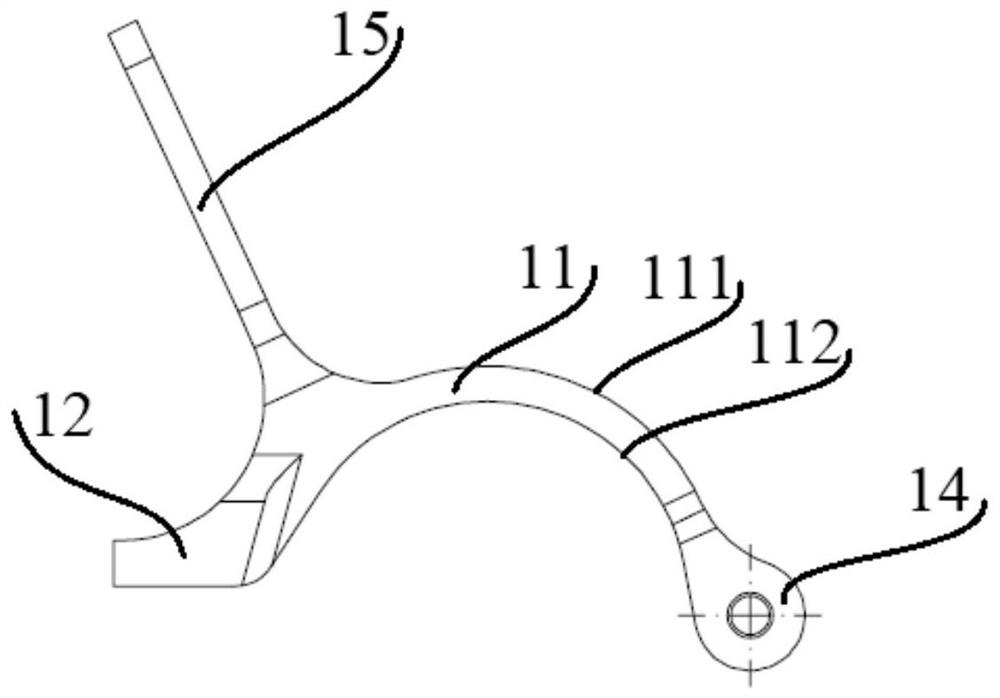

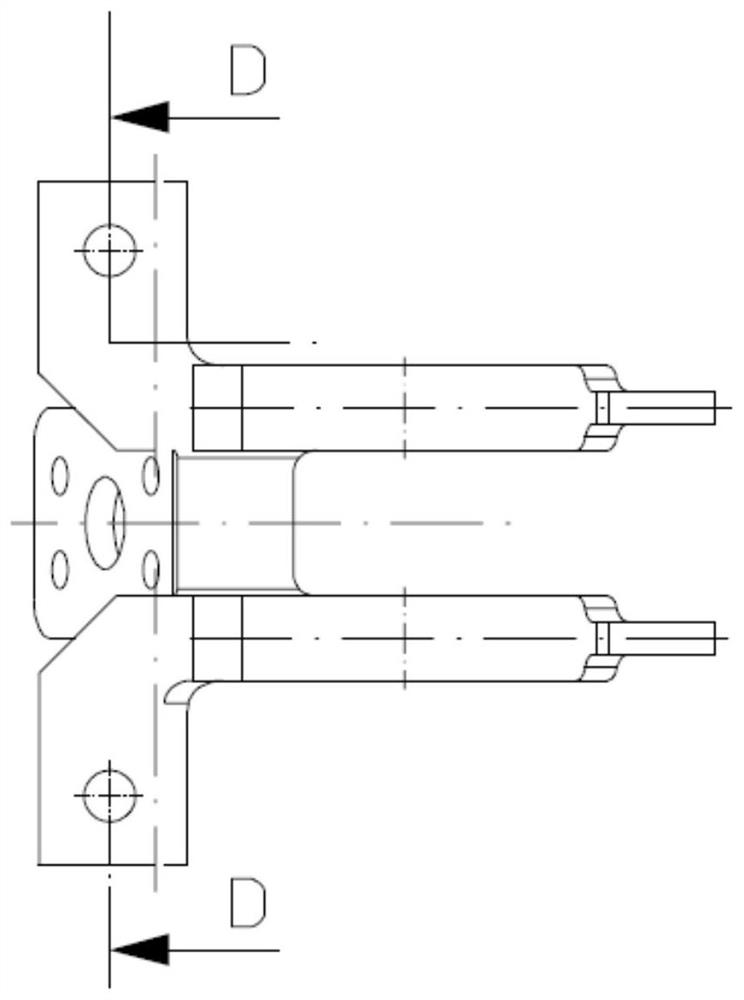

[0035] The structure of the special-shaped part 1 processed in the present embodiment is as Figure 1-4 As shown, the special-shaped part 1 is a thin-walled curved surface structure as a whole, and its middle part is a curved part 11, which has an upper profile 111 and a lower profile 112 with substantially similar shapes. The upper profile 111 and the lower profile 112 are composed of two A surface formed by perpendicular stretching of a dimensional curve. The bent portion 11 extends to one side to form two transversely symmetrical mounting ears 12, and the mounting ears 12 are provided with mounting holes, and the bent portion 11 extends to the other side to form two transversely symmetrical elongated portions 13, the two elongated portions The ends of 13 are provided with lugs 14 opposite to each other, and the lugs 14 are provided with mounting holes. A fixing plate 15 is provided extending along the normal direction of the upper profile 11 on the bending portion 11, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap