Foldable type table trolley

A folding and logistics technology, applied in trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of scratching and scratching of items, large space, increasing the weight of the logistics trolley, etc., and achieves a simple structure, easy to prepare, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

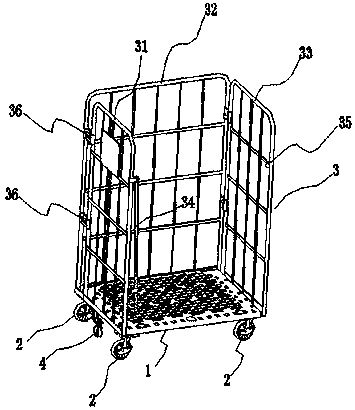

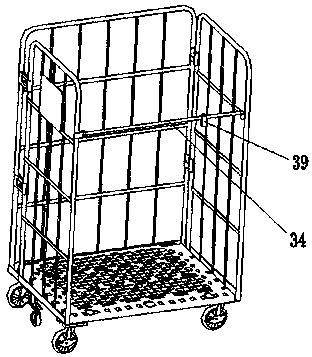

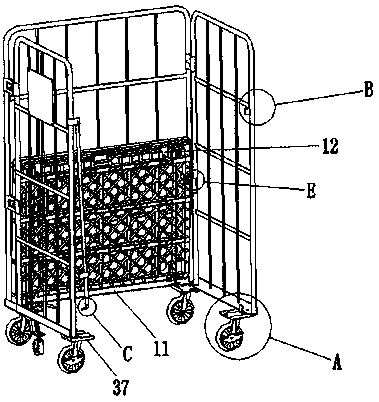

[0031] A foldable logistics trolley includes a bottom plate 1, traveling wheels 2, guardrail components 3 and stable wheels 4.

[0032] Wherein, the guardrail assembly 3 includes a first guardrail board 31, a second guardrail board 32, a third guardrail board 33, a stop bar 34, a stop bar clip 35, a fixing clip 36 and a bottom plate limiting convex edge 37; The first guardrail 31 and the third guardrail 33 are respectively movably connected to the two sides of the second guardrail 32 through the fixed clips 36; 36, the head of the stop bar 34 is provided with a locking projection 341; A notch 351 corresponding to the locking protrusion 341 is formed on the lever clamp 35 . The bottom plate 1 is movably connected to the bottom side of the second guardrail 32 through the folding rotating shaft 11; the bottom plate 1 is provided with an elastic clamping block 13 that is adapted to the side of the second guardrail 32; The traveling wheel 2 is connected to the bottom of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com