A method for preparing optically pure L-menthol

A technology of menthol and isopulegol, which is applied in the field of preparing optically pure L-menthol, can solve the problems of low space-time efficiency, limited raw materials, high energy consumption, etc., and achieve high stability, high activity and stability, The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

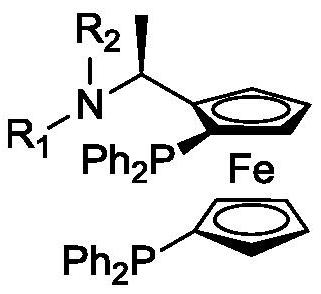

Method used

Image

Examples

Embodiment 1

[0039]In an argon atmosphere, 31.2mg of bisphosphine ligand (1), 24.7mg [Rh(cod)Cl]2Dissolve in 15mL toluene, and transfer to a 50mL autoclave, add 15.22g racemic isopulegol (ee=0%, L-isopulegol / D-isopulegol=1:1 (mol)) Inject into the autoclave, pass hydrogen to replace the gas in the autoclave three times, and adjust the pressure to 50 bar. Turn on the stirring and react at 80°C for 10 hours. The conversion rate of L-isopulegol measured by gas chromatography is 99.9%. The product is L-menthol with an optical purity of 99ee%. The raw material is L-isopulegol. The yield of L-menthol based on alcohol was 99.8%.

Embodiment 2

[0041]In an argon atmosphere, 61.9mg bisphosphine ligand (1), 48.8mg[Rh(cod)Cl]2Dissolve in 15 mL of toluene, and transfer to a 50 mL autoclave, inject 15.22 g of L-isopulegol (ee=98%) into the autoclave, pass hydrogen to replace the gas in the autoclave for three times, and adjust the pressure to 50 bar. Turn on the stirring and react at 80°C for 10 hours. The conversion rate of L-isopulegol measured by gas chromatography is 99.9%. The product is L-menthol with an optical purity of 99ee%. The raw material is L-isopulegol. The yield of L-menthol based on alcohol was 99.8%.

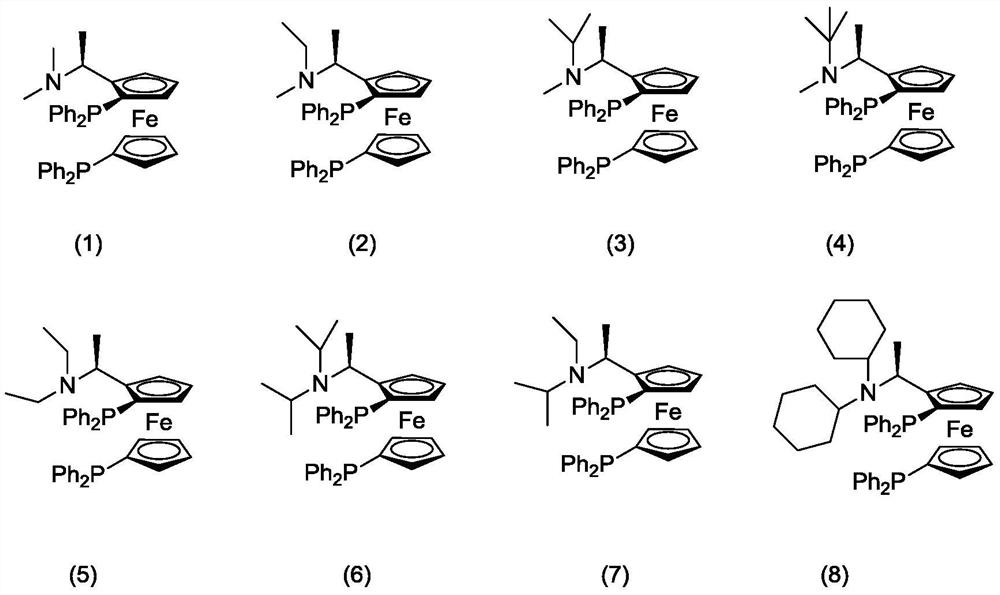

Embodiment 3-9

[0043]In an argon atmosphere, 0.05mmol and 24.7mg [Rh(cod)Cl] of bisphosphine ligands of structural formulas (2)-(8) are used respectively2Dissolve in 15mL toluene, and transfer to a 50mL autoclave, add 15.22g racemic isopulegol (ee=0%, L-isopulegol / D-isopulegol=1:1 (mol)) Inject into the autoclave, pass hydrogen to replace the gas in the autoclave three times, and adjust the pressure to 50 bar. Turn on the stirring, and after reacting at 60°C for 15 hours, use gas chromatography to determine the conversion rate of L-isopulegol in the raw material and the yield of L-menthol based on the L-isopulegol in the raw material, and the product L-menthol The optical purity of the alcohol is shown in Table 1.

[0044]Table 1 Reaction conditions and results

[0045] Example Bisphosphine ligand Conversion rate Yield ee value 3(2)92.5%92.0%96% 4(3)86.5%85.8%98% 5(4)83.2%82.7%94% 6(5)91.4%90.6%95% 7(6)84.6%83.2%92% 8(7)81.3%79.8%96% 9(8)79.5%78.7%91%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com