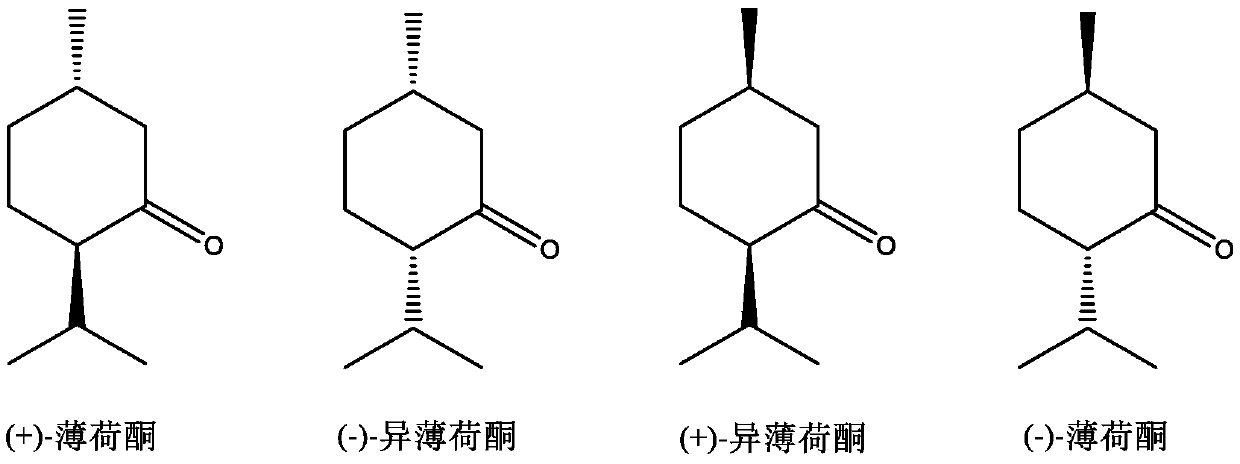

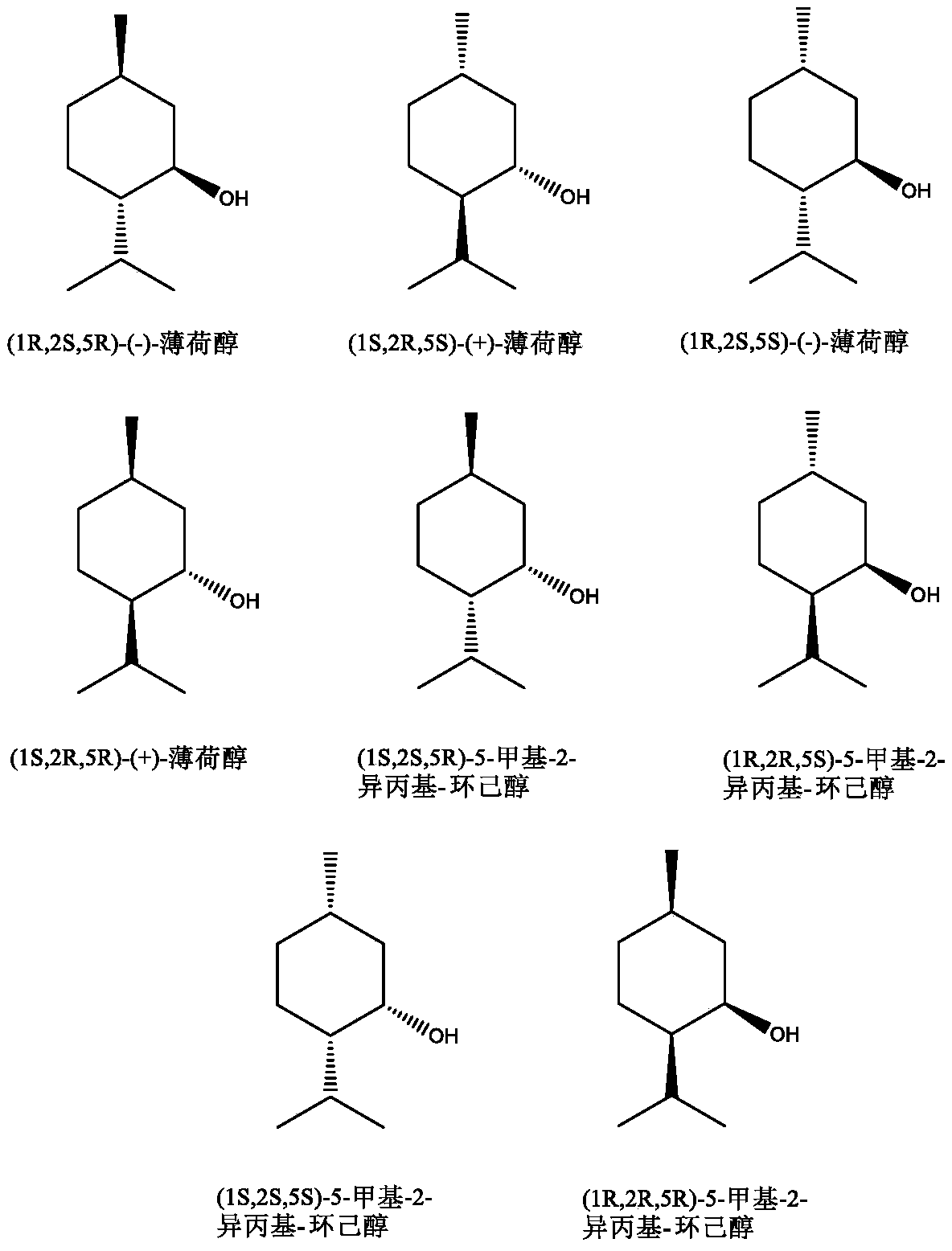

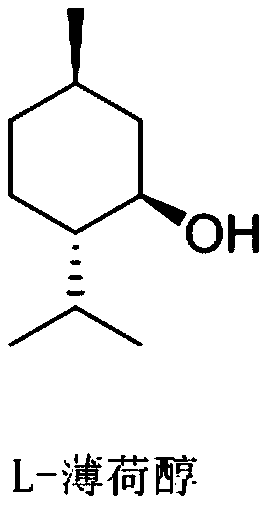

Method for preparing optically-pure L-menthone and catalyst for the method

A technology of menthone and catalyst, which is applied in the field of preparing optically pure L-menthone method and related catalysts, can solve the problems of limited turnover increase, adverse environmental impact, short catalyst life, etc., and achieve the effect of increasing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Under an argon atmosphere, 26.1 mg of salen manganese compound (1) (4-tBu-Salen Mn, purchased from Aldrich Company), 15.42 g of racemic menthol (ee=0%, L-menthol / D-menthol= 1:1 (mol)) was dissolved in 15mL of acetonitrile, and transferred to a 50mL reactor, started stirring, cooled to 0°C, slowly added 5.7g of 30% hydrogen peroxide solution dropwise, reacted at 0°C for 1h, and used gas chromatography The measured L-menthol conversion rate is 99.9%, the product is L-menthone, the optical purity is 99ee%, and the yield of L-menthone is 99.8% based on the L-menthol in the raw material.

Embodiment 2

[0060] Dissolve 32mg of salen manganese compound (1) and 15.42g of L-menthol (ee=98%) in 15mL of acetonitrile under an argon atmosphere, and transfer them to a 50mL reactor, start stirring, cool down to 0°C, and slowly add 17g of 30% hydrogen peroxide solution was reacted at 0°C for 3 hours, and the conversion rate of L-menthol was measured by gas chromatography to be 99.9%, and the product was L-menthone with an optical purity of 99ee%. The yield of L-menthone was calculated to be 99.8%.

Embodiment 3-5

[0062] Under an argon atmosphere, the salen manganese compounds (4-tBu-2-Me-Salen Mn(2), 2,4-di-tBu-Salen Mn(3), 4- Naphthalen-Salen Mn (4) purchased from Aldrich Company) 0.05mmol, 15.22g racemic menthol (ee=0%, L-menthol / D-menthol=1:1 (mol)) was dissolved in 15mL acetonitrile, and transferred to a 50mL reaction kettle, started stirring, cooled to 0°C, slowly added 5.7g of 30% hydrogen peroxide solution dropwise, and reacted for 5h at 0°C, used gas chromatography to measure the conversion rate of L-menthol in the raw materials and the See Table 1 for the yield of L-menthone in terms of L-menthol and the optical purity of product L-menthone.

[0063] Table 1 Reaction conditions and results

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com