Textile fabric pre-shrinking device

A textile fabric, pre-shrinking technology, applied in the processing of textile materials, processing textile material carriers, processing textile material containers, etc., can solve the problems of no motor protection, single function, complex structure, etc., to avoid uneven cloth surface, High degree of intelligence and the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

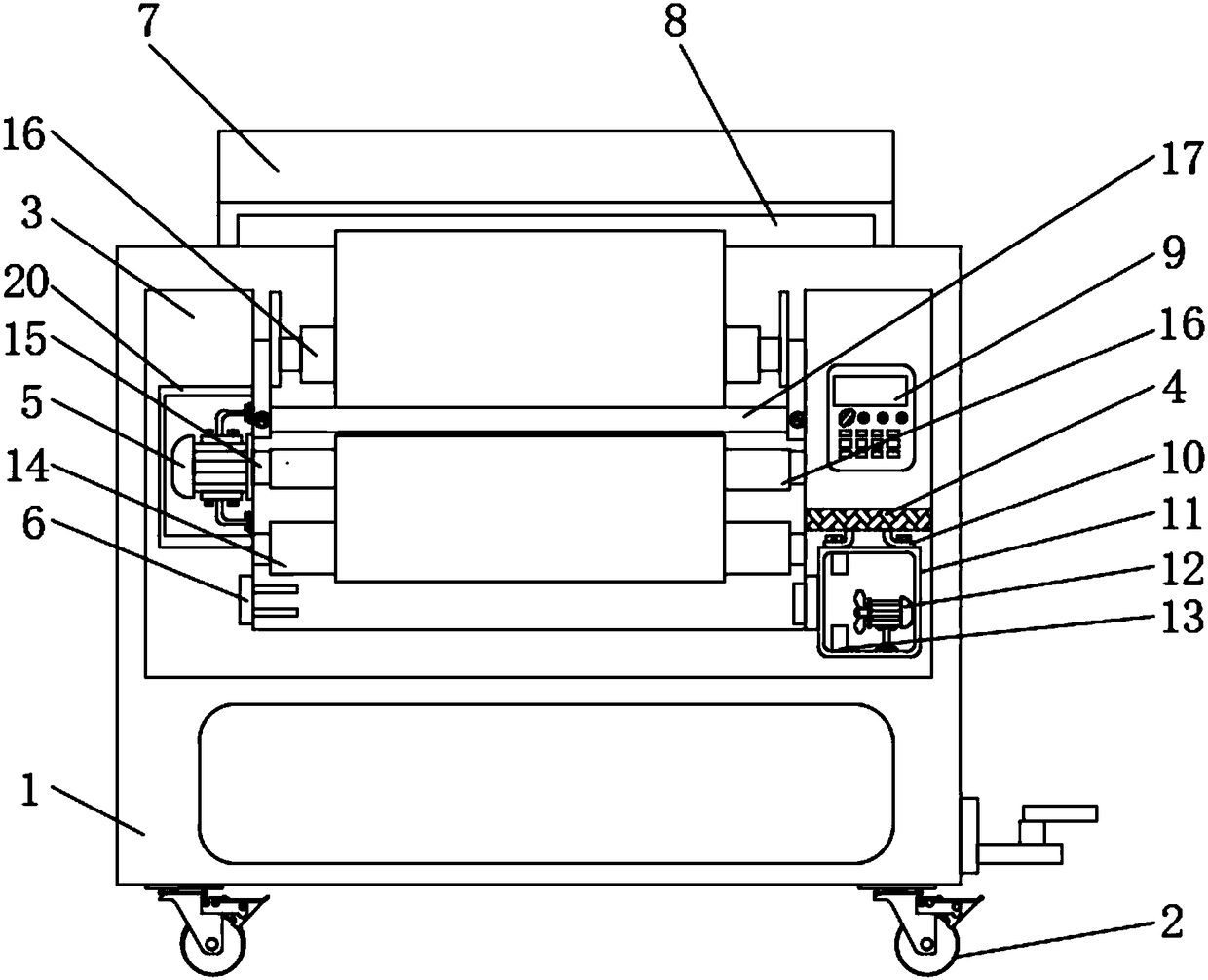

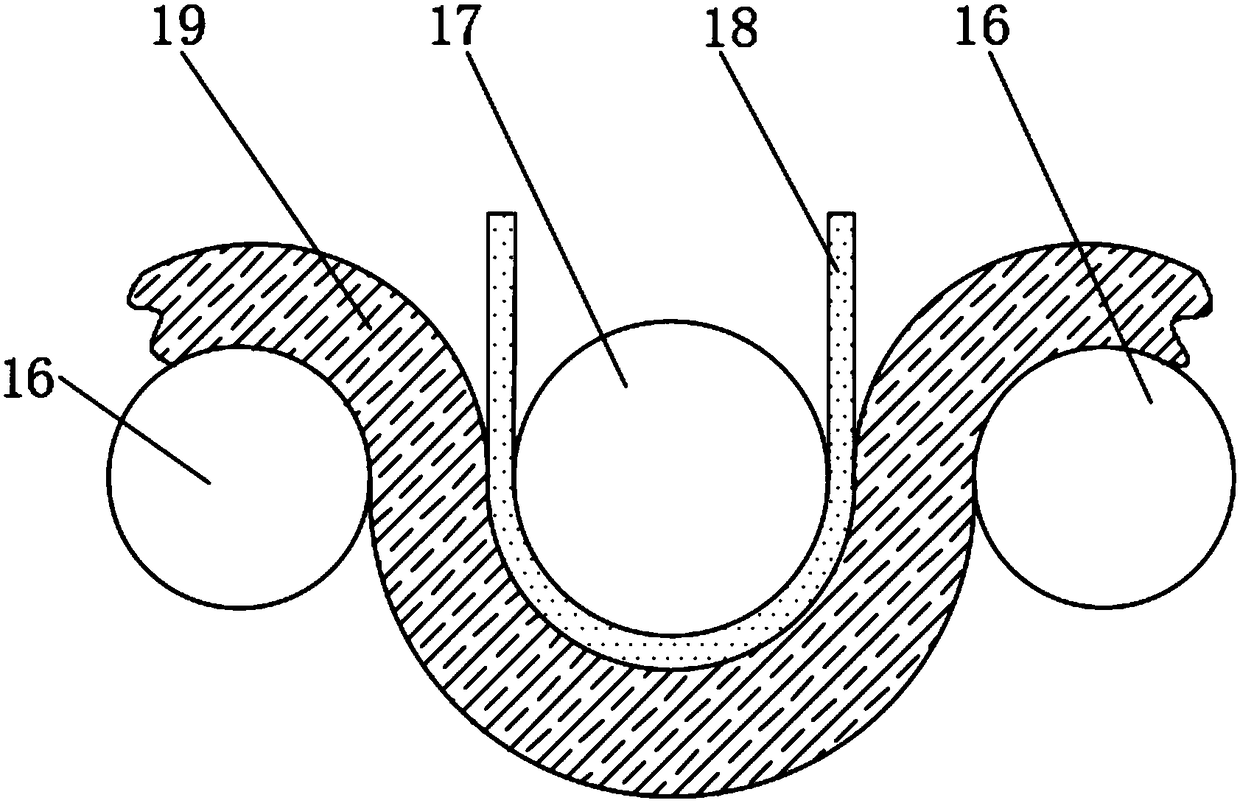

[0020] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a textile fabric pre-shrinking device, including a pre-shrinker body 1, a working chamber 3 is provided on the front surface of the pre-shrinker body 1, and the bottom of the pre-shrinker body 1 The universal wheel 2 is fixedly installed, the upper end of the pre-shrinker body 1 is provided with a cooling chamber 7, and the upper end of the pre-shrinker body 1 is provided with an inlet 8 on the side close to the cooling chamber 7, and the inside of the working chamber 3 is provided with a support plate 4. A motor 5 is fixedly installed on one side of the inner wall of the working chamber 3, a humidity sensor 6 is embedded and installed on one side of the inner wall of the working chamber 3 close to the lower part of the motor 5, and a control switch 9 is provided on the front surface of the working chamber 3, The inside of the working chamber 3 is provided with a bracket 10 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com