Program-controlled ammunition over-burning system

A ammunition and program-controlled technology, applied in blasting and other directions, can solve the problems of low destruction efficiency and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

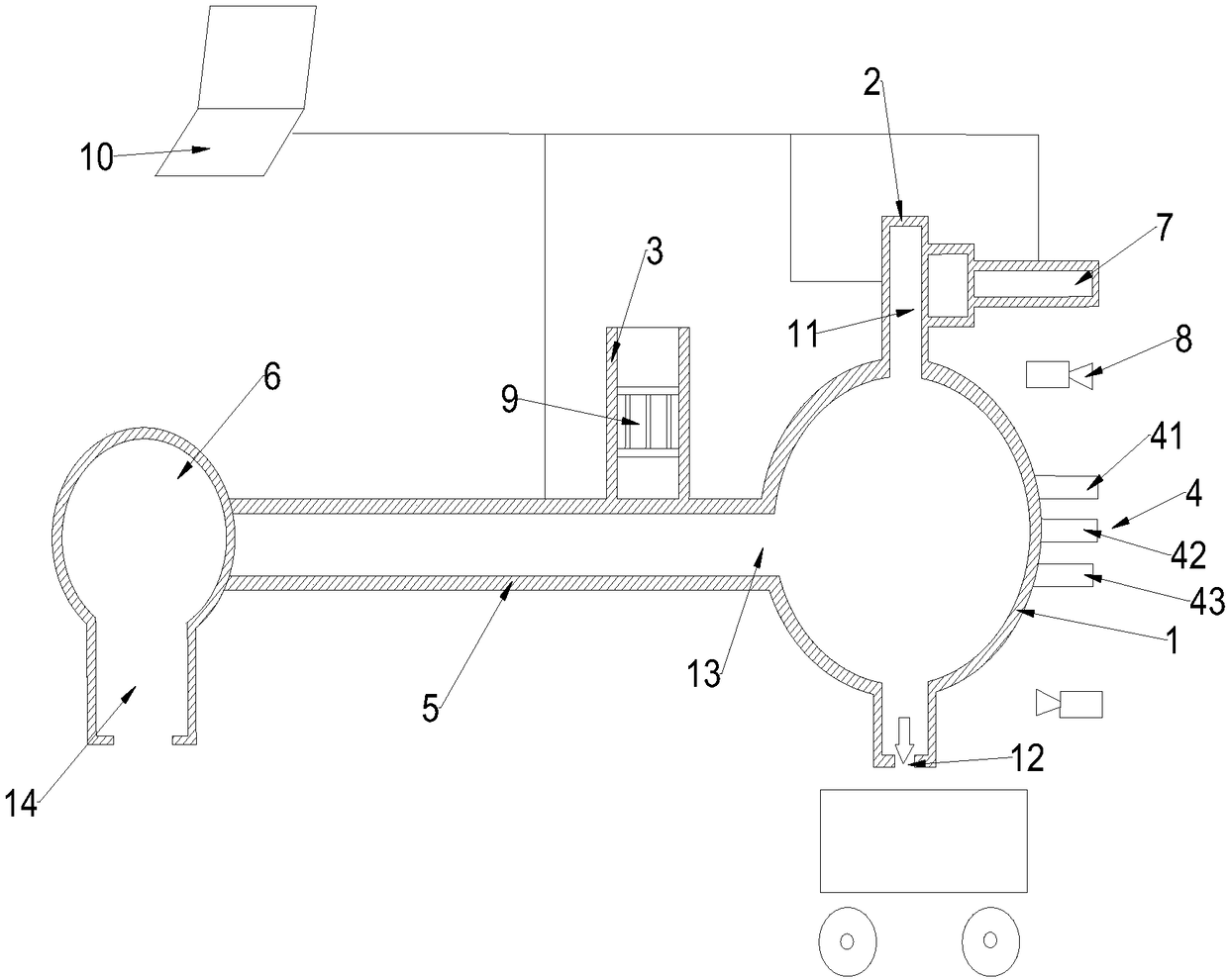

[0017] Such as figure 1 As shown, the program-controlled ammunition burning system includes a destruction furnace 1, a drilling machine 2, a smoke exhaust channel 3, a monitoring device 4, and a heating device. The destruction furnace 1 is a metal shell with a cavity structure. In this embodiment, the destruction The shell of the furnace 1 is a single-layer shell. One end of the destruction furnace 1 is provided with a feed port 11, the other end is provided with a discharge port 12, and one side of the destruction furnace 1 is provided with an explosion vent 13, and the drilling machine 2 is installed In the inlet 11, the drilling machine 2 is controlled by the remote console 10. When the waste ammunition enters from the inlet 11, the remote console 10 controls the drilling machine 2 to punch the waste ammunition to ensure that the waste ammunition is in It can burn or explode completely when burned. Further, in this embodiment, a screw conveyor 7 is also installed in the fee...

Embodiment 2

[0022] This embodiment is the same as the embodiment 1 in that the programmed ammunition burning system in this embodiment includes a destruction furnace 1, a drilling machine 2, a smoke exhaust channel 3, a monitoring device 4 and a heating device, among which the drilling machine 2 The smoke exhaust channel 3 and the monitoring device 4 are the same as the drilling machine 2, the smoke exhaust channel 3, and the monitoring device 4 in the embodiment. The above-mentioned devices have been described in detail in the first embodiment and will not be described in detail here. The embodiment is the same as the embodiment 1 in that the shell of the destruction furnace 1 in this embodiment is a double shell, the inner shell is completely closed, the heating device is an electromagnetic heating device, and the electromagnetic heating device is installed in the inner shell of the destruction furnace 1. When working, the electromagnetic heating device uses electromagnetic heating to hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com